An Automated Solution for Turbomachinery Blade Meshing.

TurboGrid is a superior turbomachinery meshing software. Its hallmark automated mesh generation capabilities rollout in a simple-to-use, streamlined workspace. The provisions offered can be adapted to a wide array of turbomachinery equipment and will produce better simulation results, regardless of your businesses market niche.

Ansys TurboGrille Proficiencies

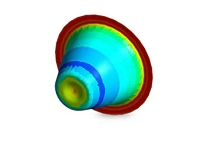

- Ansys TurboGrille is the industry-leading automated mesh generation tool. Although it is automated, you’ll be able to customize your experience by defining detailed mesh settings, such as desired mesh size or blade boundary layer resolution.

- Furthermore, it contains a rapid mesh quality feedback and will help you fix regions that do not meet target quality. TurboGrid contains many tools that exhibit similar display properties to other blade design software such as the 2-D blade-to-blade views and meridional planes.

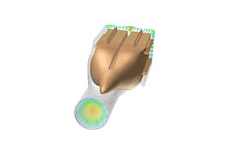

- It is a very intuitive workspace that allows for simple, yet powerful, mesh generation including automated capabilities in Axial, Radial and Mixed Flow, Meridional Splitter, Splitter Vanes, Fillets, SMART Tip Clearances, and Boundary Layer Refinement.

TurboGrille, the First-Class Solution to T-MAC Blade Meshing.

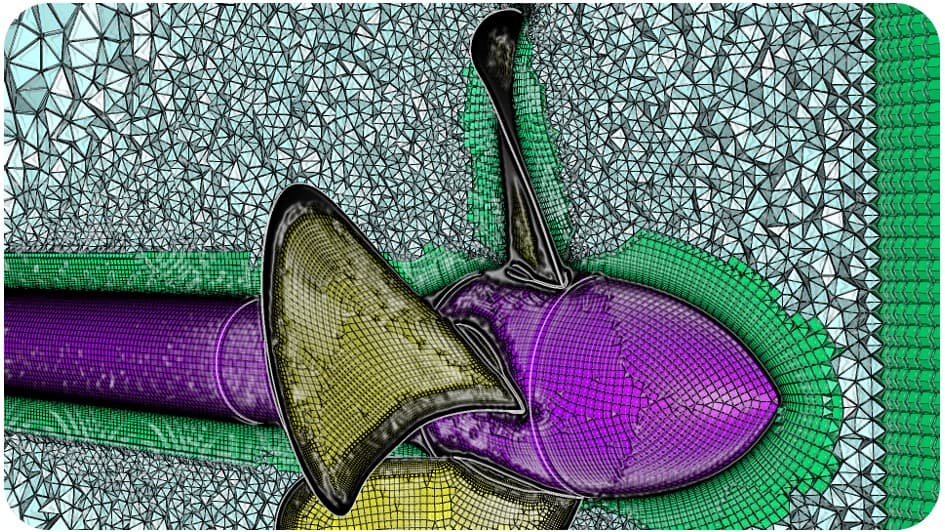

- TurboGrid software includes novel technology that targets complete automation combined with an unprecedented level of mesh quality for even the most complex blade shapes.

- The desired final mesh size is defined (and, optionally, the blade boundary layer resolution), and all the other steps can be performed automatically to produce a mesh of extremely high quality.

- Grid angles are exceptionally precise, mesh sizes transition smoothly, and high aspect-ratio elements are generated in the near-wall regions to resolve these regions efficiently and capture boundary layer flows accurately.

What exactly is Topology Optimization (TO)?

The goal of TO is generally to maximize part performance by mathematically modelling and optimizing for factors such as external forces, load conditions, boundary conditions, constraints, and material properties within the design parameters.

- Isolated Emphasis on Turbo ► The TurboGrid software architecture for design, analysis and optimization provides an integrated and streamlined approach to turbomachinery design.

-

Ease of Use ► Offering a user-friendly point-and-click environment with display functions familiar to blade designers, including 2-D blade-to-blade and meridional planes for viewing flow path and blade position. The view is updated automatically with each input to reflect the latest changes.

- Explicitly for blades with clearances at the shroud, or even at the hub, Ansys TurboGrid provides an all-encompassing solution.

- Users can specify the amount of tip clearance in numerous ways: for example, as a percentage of span or at a specified distance from the hub or shroud.

- The grid in the tip can be either matching or nonmatching along the center of the blade thickness, ensuring optimal grid quality and accurate prediction of blade tip flow.

- Unlike conventional software requiring downtime for analysis, TurboGrid provides immediate feedback on mesh quality.

- Precise criteria in instantly available such as grid skew angles, mesh expansion rates and aspect ratios of mesh elements.

- Any mesh elements that do not meet target quality criteria are highlighted, guiding the user in adjusting user input and controls accordingly.

- TurboGrid also permits users to import customized CAD models and mesh secondary flow paths, such as bleeds, cavities, labyrinth seals, back disc cavities and ported shrouds. A simplified virtual geometry can also be specified and exported to third-party applications.

- In addition, Hub and Shroud casing can be designed by manipulating their meridional contours. This supplemental feature is available when solids are activated for the impeller, neighboring static components are specified, and an offset between impeller and neighboring components is loaded.

- The secondary flow path is defining the ‘real’ object geometry. This can make all the difference in your business design.