Design Elements

|

Challenges in the Automotive Industry

|

Simulation Benefits in Automotive

|

Aerodynamics

|

- Resolve pressure distribution around the vehicle

- Minimize vehicle drag (to improve fuel economy)

- Assess vehicle handling and stability (side forces, lift)

|

- High-end turbulence models

- Sophisticated and accurate numerics

- Highly efficient transient solvers

- Mesh-adapt-on-the-fly ability

- Industry-leading parallel scalability

|

Automotive Acoustics

|

- Noise propagation for external and internal flows

- Qualify acoustic sources

- Determine dominant frequencies and sound pressure level (SPL)

- Understand effect of modifications to local geometric features on SPL and frequency

|

- High-end turbulence models

- Highly efficient transient solvers

- Highly accurate numerics

- Built-in acoustics-specific tools

- Industry-fastest turnaround times

|

Airbag Inflators

|

- Optimize inflator design from the aspect of gas flow delivery in the airbag

- Gas flow data are input for crash simulations

- Need detailed characterization of the gas flow inside and/or outside the inflator

|

- Robust explicit solver able to deal with highly compressible, unsteady, flows and propagating pressure waves

- Species transport model

|

Brakes & Wheels

|

- Design brakes and wheels that are durable and can sustain variable loads

- Predict stress and fatigue

- Predict local temperature distributions and thermal loads

- Optimize brake venting

|

- Flow and structural solution from the same CAE vendor

- Easy and seamless transfer of CFD and FEA data between applications

|

Climate Control System

|

- Design HVAC system able to provide thermal comfort to passengers over a wide range of driving and ambient conditions

- Deliver appropriate cabin airflow for clearing windshield and windows as required by safety regulations

- Optimize performance of HVAC components

|

- Hexcore technology for efficient meshing

- Robust and accurate solver regardless of mesh type

- Deicing and defogging models

- Solar load model

|

Electronics (automotive)

|

- Design components capable of sustaining harsh operating environments

- Proper thermal management is crucial for reliability and durability

- Accelerated failure mechanism in materials

- Packaging constraints

- Vibrations

|

- Variety of products targeted for electronics, from full-feature applications to highly application-focused and automated vertical tools

- Easy and seamless transfer of flow and structural data between CFD and FEA

|

FSI Simulations

|

- Capture the flow-induced structural deformations (one-way coupling)

- Capture the alterations of the fluid flow due to structural deformations (two-way coupling)

|

- Both 1-way and 2-way FSI simulations can be performed entirely within the Ansys Workbench environment

- A single environment with a consistent graphical user interface, making it easier to learn and use

- Simulation process completely streamlined

- Automated mesh morphing

- Both CFD and FEA results can be simultaneously post-processed in the Ansys CFX post-processor

|

Headlights & Lamp Housing

|

- New polymer materials have lower thermal resilience than glass

- Thermal stresses caused by absorption of emitted light

- Condensation is visible in case of clear panes

- Flow distribution needs to be optimized for proper ventilation

|

- Complete solution: CFD and FEA

- Choice of several radiation models

- Condensation model

- Material nonlinearity

- Easy mapping of CFD data onto FEA

|

Underhood Thermal Management

|

- Predict cooling system performance (e.g. air flow distribution in heat exchangers, top hose temperature, fan-off temperature…)

- Minimize simulation turnaround time while meeting accuracy targets

- Preprocessing: Complexity of the geometry, number of parts (in hundreds), dirty CAD data, etc.

|

- Powerful pre-processing tools (e.g. TGrid, Ansys ICEM CFD)

- Full suite of physical models (e.g. radiation, buoyancy, shell conduction, fan model, heat exchanger model)

- Robust and accurate numerics via automotive software

- Fully parallelized calculations for fast turnaround

- Fully coupled solution with major 1-D fluid system (e.g. Flowmaster) and engine simulation codes (e.g. GT-Power and WAVE)

|

Automotive Mechanics

|

- Analyze the mechanisms of complex assemblies involving many parts

- Determine forces experienced at the joints

- Predict stresses in critical regions

- Rapid modeling of mechanisms and optimizing the design

|

- Automatic joint detection for complex assemblies

- Quickly switch simulation from fully- rigid to flexible in the same environment

|

Body in White

|

- NVH and point mobility analysis of full BIW structures

- Accurately model spot welds

- Crash simulation of structure

|

- Feature rich surface meshing tools including variable thickness

- Auto creation of spot welds from weld data

- Ability to export the model from static to crash analysis

|

Hyperelastic Seals

|

- Predict leakages and failure of seals

- Highly non-linear material and load behavior

- Complex physics involving self-contact

|

- Ability to model non-linear materials

- Easy to set up self-contact

- Easy to model 2-D as well as 3-D solutions

- Advanced diagnostic tools to help convergence

|

Fuel Cells

|

- Channel design that optimizes distribution of oxygen (hydrogen) to the cathode (anode)

- Water management via automotive consulting

- Thermal stresses and cooling plate design

- Property variation

- Space limitations

|

- Probabilistic design in virtual prototypes

- Minimize costly physical prototypes using analysis based on first principle physics (electrochemistry, fluid flow, heat and mass transfer, structural mechanics)

|

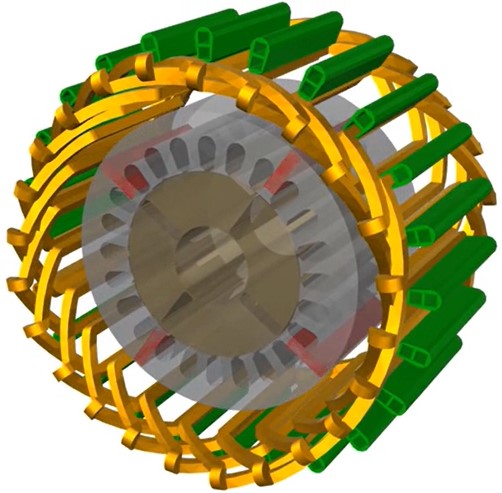

Battery Packs

|

- Increase power capability, while avoiding hot spots that cause premature failure

- Insure proper thermal management of the battery pack for performance and reliability

- Battery pack performance impacted by performance of individual cells and modules

- Capture heat transfer of the actual cell or module (case, terminal posts, connectors, interconnects, relief valves, seals, etc.)

|

- Multiphysics modeling capabilities (electro/thermal, CFD, FEA) all in a single CAE package

|