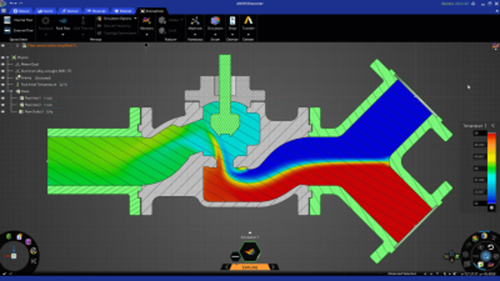

Case Study: Effect of Flows on Thermal Shock Clearances in a Globe Valve

The effectiveness of valves in a nuclear power plant must be demonstrated under challenging operating circumstances. Approximately 225°C thermal shocks are one of the certification tests that satisfied this empirical testing.

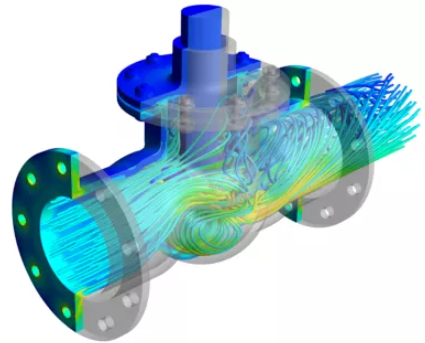

Here, such shocks are experimentally and numerically investigated on a large globe valve with a nominal diameter of 150 mm. Ansys Maxwell‘s automated testing loop is the internal software site of the experimental campaign.

In pressurized cold and hot water, 10 thermal shocks are carried out one after the other. The tested valve has 40 thermocouples installed evenly along its height.

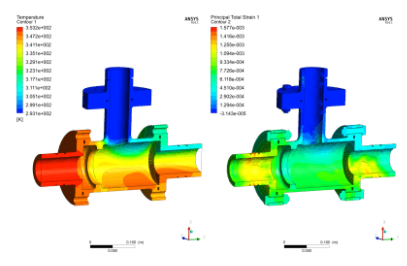

The body-bonnet flange’s 10 studs are equipped with strain gauges. In effect, enabling close-monitoring of the evolution of the clamping forces within the flange. From here, it is carried out a 3D numerical simulation of such a shock in the valve.

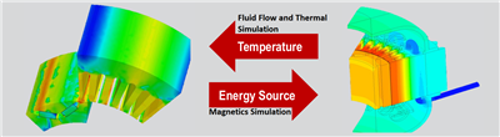

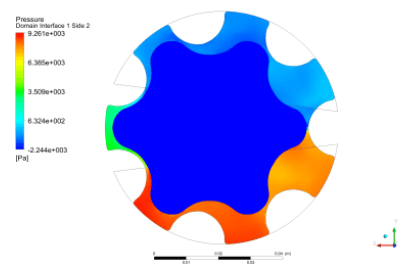

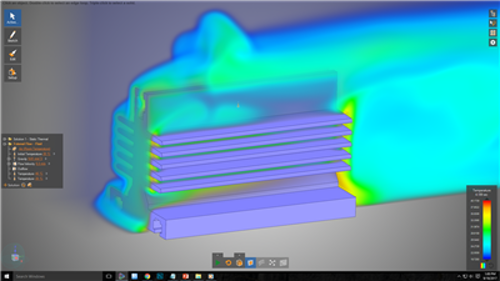

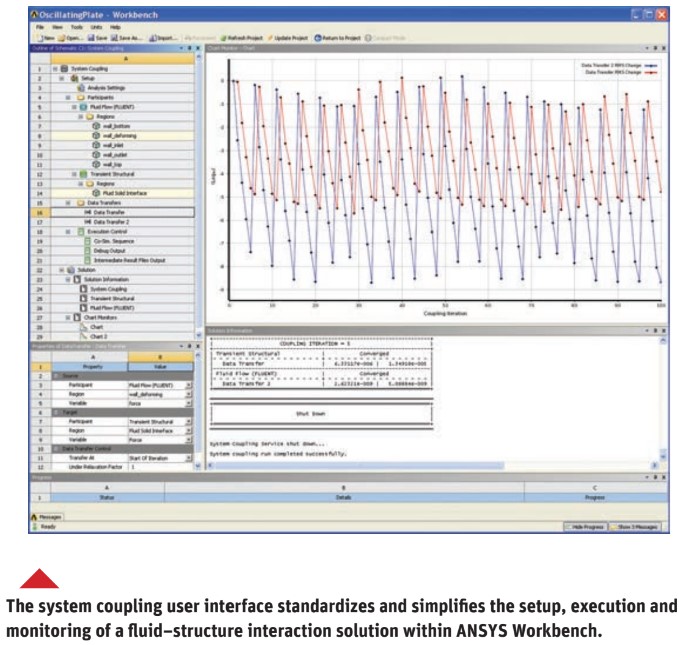

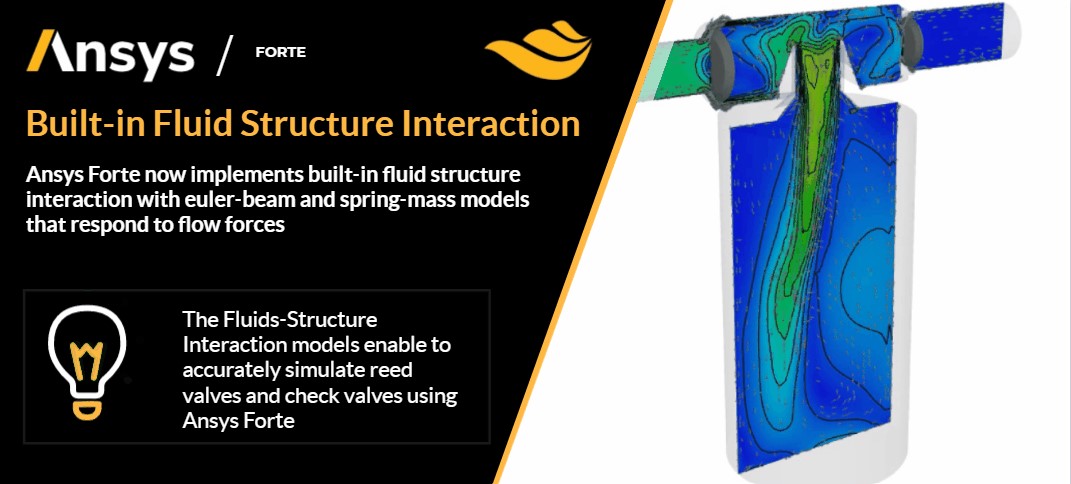

A series of multiphysics simulations, including fluid, heat conduction, kinetics, and mechanics, are used to carry out simulations. With multiple contacts, the mechanical simulation represents over 50 different pieces. Pertaining to Fluid-Structure Interaction (FSI) Consulting services, this simulation is presented in two different iterations. The second of which, accounts for the heat transfer that occurs in clearances.

When it comes to the temperature in the studs, there is a high correlation between modeling and experiment. Only the second simulation is able to accurately capture the tightening changes. That is, seen experimentally at the start of cold and hot shocks in terms of clamping forces.

For more information on this case study, contact our engineering experts HERE.