Industrial equipment and rotating machinery are designed by the need to deliver stronger performance with improved efficiency, safety, and durability to perform the necessary tasks.

However, as global integration pushes manufactures and heavy industries alike, the need to optimize processes and mitigate product failures has become more essential than ever.

Designers and Analysts look at every aspect of the machines to find areas to improve for enhanced performance.

Having to take in many factors such as emissions of NOx, SOx, hydrocarbons, and soot, design engineers face several challenges in making energy efficient machinery while addressing emissions guidelines and standards.

Ansys Multiphysics capabilities offer the ability to factor in various real-world interactions and stresses to ensure accurate predictability in machine design.

Common Mechanical Testing services requested by clients across the United States and Canada.

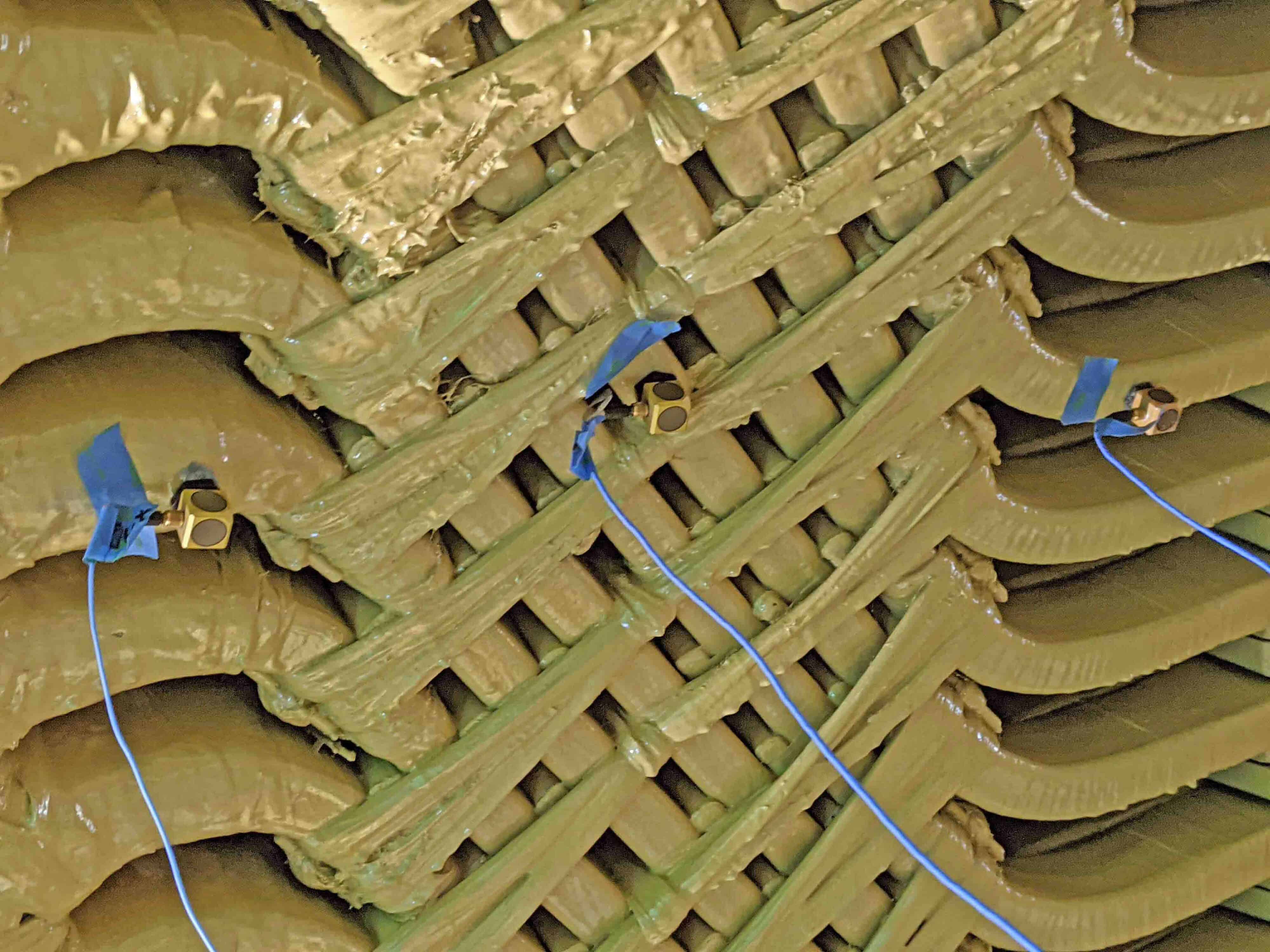

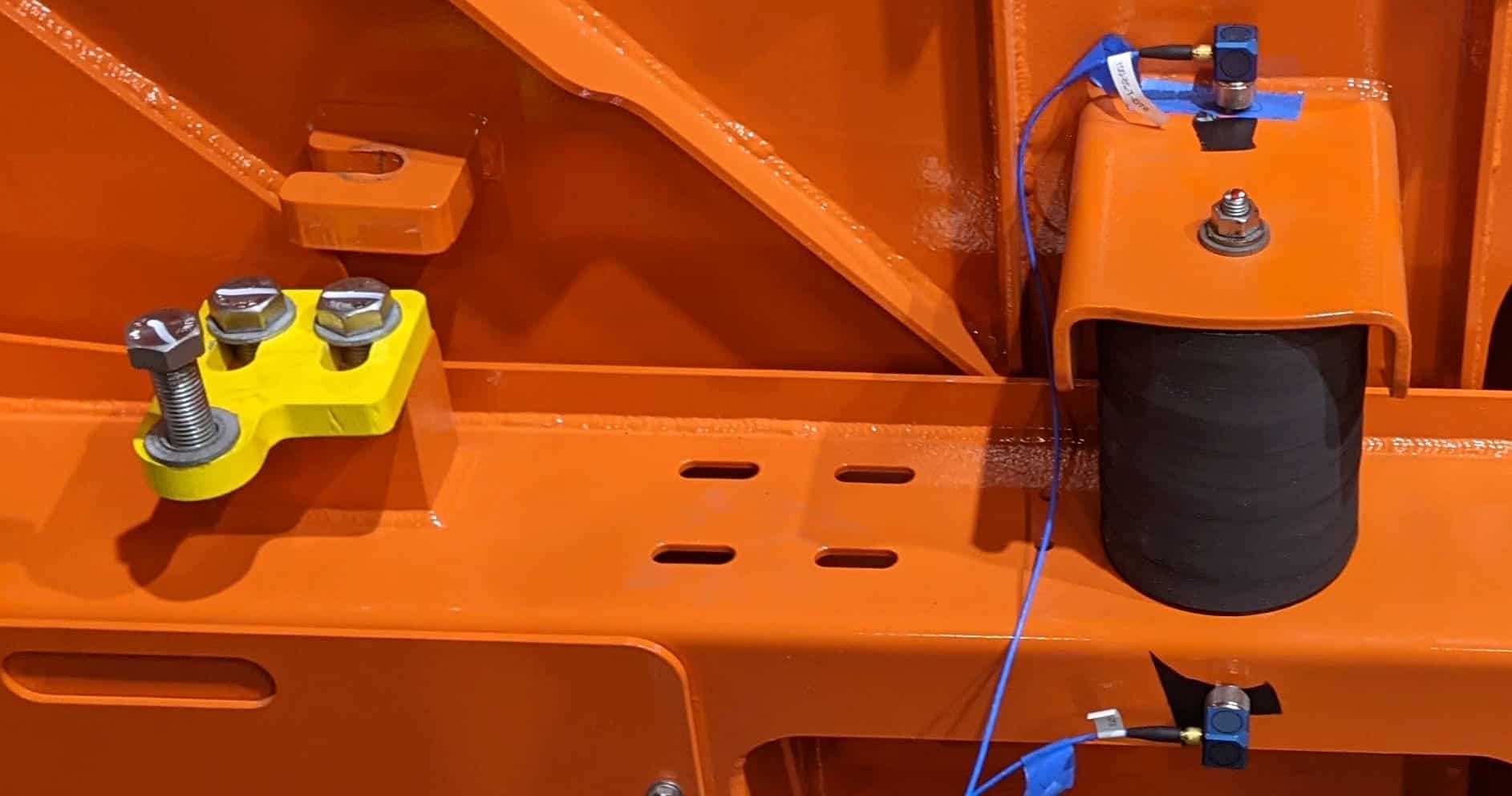

An instrumented modal hammer is used to perform a driving point measurement at the end winding series caps and phase connections.

Each location is excited and measured in three directions. Multiple impacts are applied in each degree of freedom with special care given to data quality and coherence.

Frequency response functions (FRFs) are calculated to provide timely preliminary results to the engineers responsible for system under repair.

An instrumented modal hammer is used to excite the structure in three directions. From here, the response is measured in multiple planes and circumferential locations for optimal spatial resolution.

Frequency response functions (FRFs) are calculated and processed in Siemens LMS to extract the natural frequencies and mode shapes.

An instrumented modal sledgehammer is used to excite the structure in multiple directions.

The response is measured in multiple planes and circumferential locations for optimal spatial resolution.

Frequency response functions (FRFs) are calculated and processed in Siemens LMS to extract the natural frequencies and mode shapes.

A mechanical engineer “taps” the core stage with a calibrated impulse hammer, sending vibrations along the structure. The collected data will validate or invalidate engineering models predicting how the structure will behave both in test and launch phases.

Applications for GVT and RAP testing include new airframe designs and modifications to established designs of fixed wing aircraft, rotorcraft, and spacecraft.

Knowledge gained from our vibration analysis services leads to practical solutions including:

Recent vibration diagnostics applications include:

SimuTech Group’s expertise in advanced vibration measurements and services has gained recognition across North America due to our quality of analysis and commitment to precision, allowing businesses to approach their engineering problems with confidence.

Advanced techniques for testing includes modal testing (rap testing or bump testing), operating deflection shape (ODS) analysis, strain gage measurements, spectrum (signature) analysis, order tracking, joint time frequency (waterfall) analysis, demodulation and finite element analysis (FEA).

These capabilities plus state-of-the-art equipment, enables SimuTech to diagnose the root cause of noise and vibration problems.