SimuTech Group provides a blade frequency testing service for new, refurbished, or reverse engineered turbine blades (buckets) to ensure that their natural frequencies are within specifications. This is especially critical for longer tuned last stage steam turbine blades that are susceptible to high-cycle fatigue failure due to resonance during operation.

Turbine blades are intended to withstand high static and dynamic stresses. Static stresses can be measured or computed with resembling accuracy, but dynamic stresses are evaluated more precisely through experimental rather than theoretical designs. Consequently, blade frequency testing requires specialized approaches by engineers well-disciplined in the field.

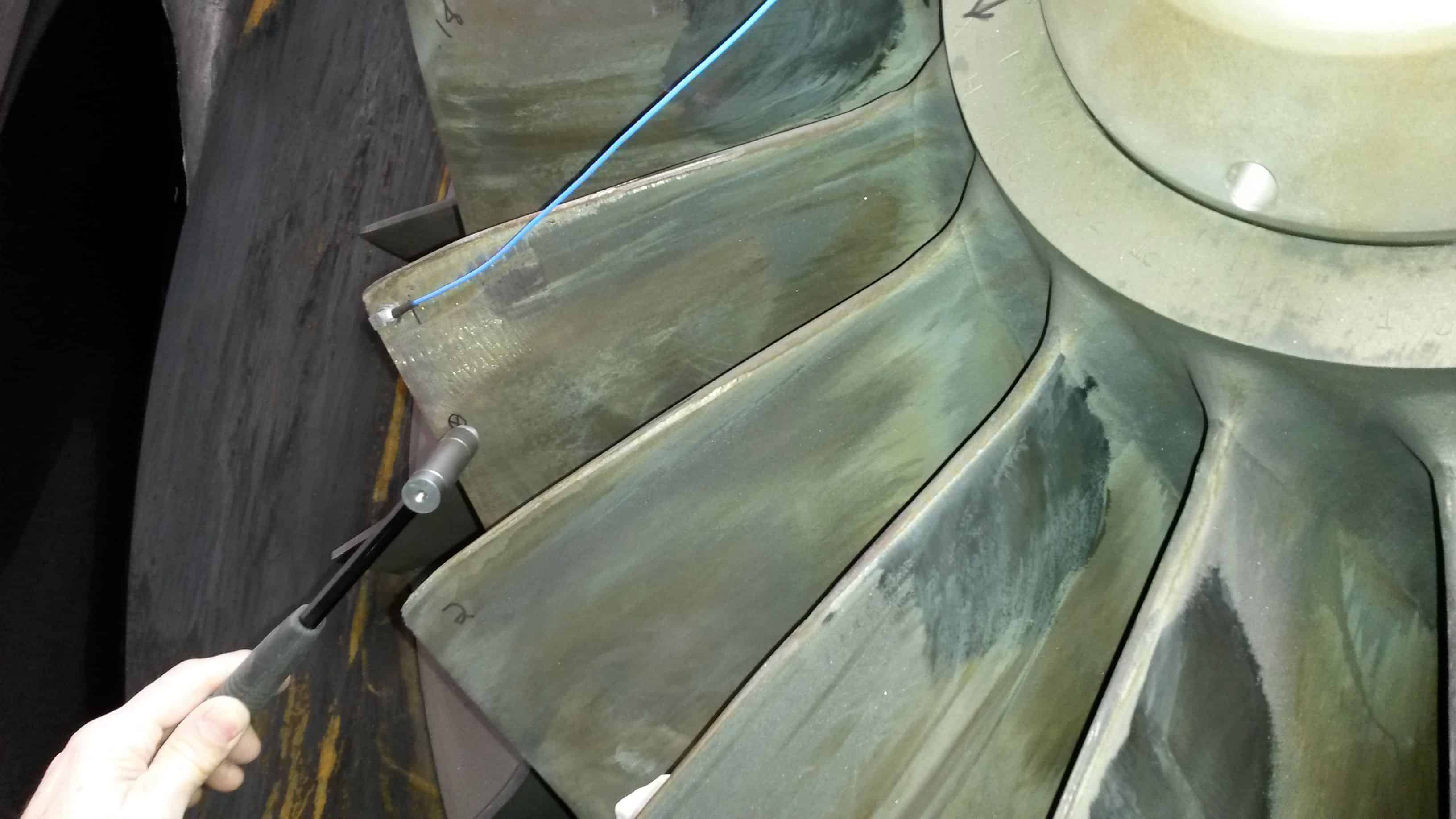

SimuTech Group performs laboratory & on-site testing of blades and blade groups on rotors, and has extensive experience with vibration test fixture design.

As for structural requirements, ensuring natural frequencies are within specifications is especially critical for longer tuned last stage steam turbine blades that are susceptible to high-cycle fatigue failure due to resonance during operation.

To ensure accuracy under various settings and conditions, SimuTech Group measures blade frequencies with distinct boundary conditions including “free-free”, fixtured, installed on a rotor, and during operation.

Due to commercial significance and core function of turbine in advanced industry, suitable design, routine testing, and upkeep of turbine blades can decrease cost and increase the life of turbines.

• “Free-Free”

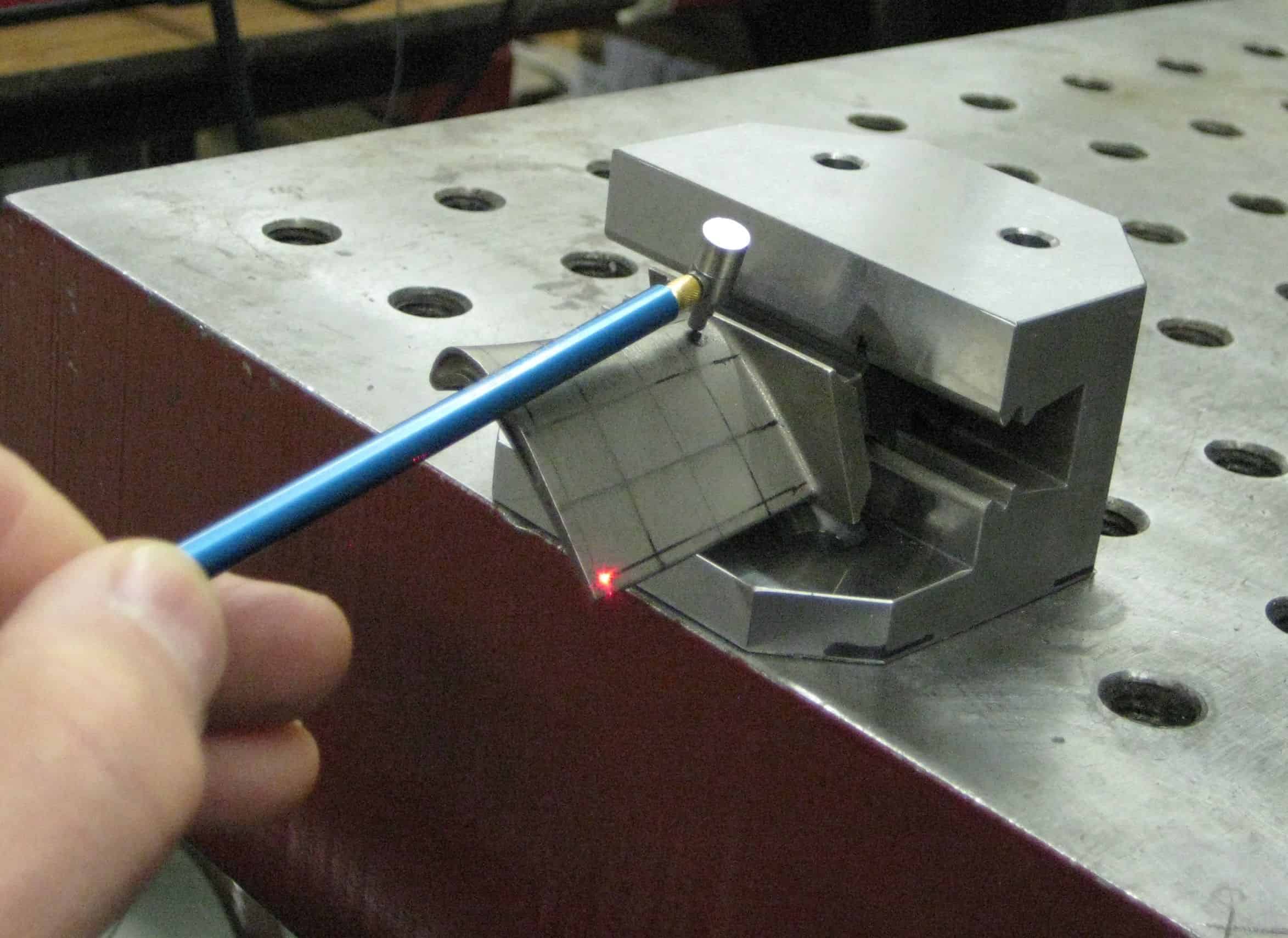

• Fixtured

• Installed on a Rotor

• During Operation

• Piezoelectric actuators

• Modal hammers

• Acoustic horns

• Shakers

• Accelerometers

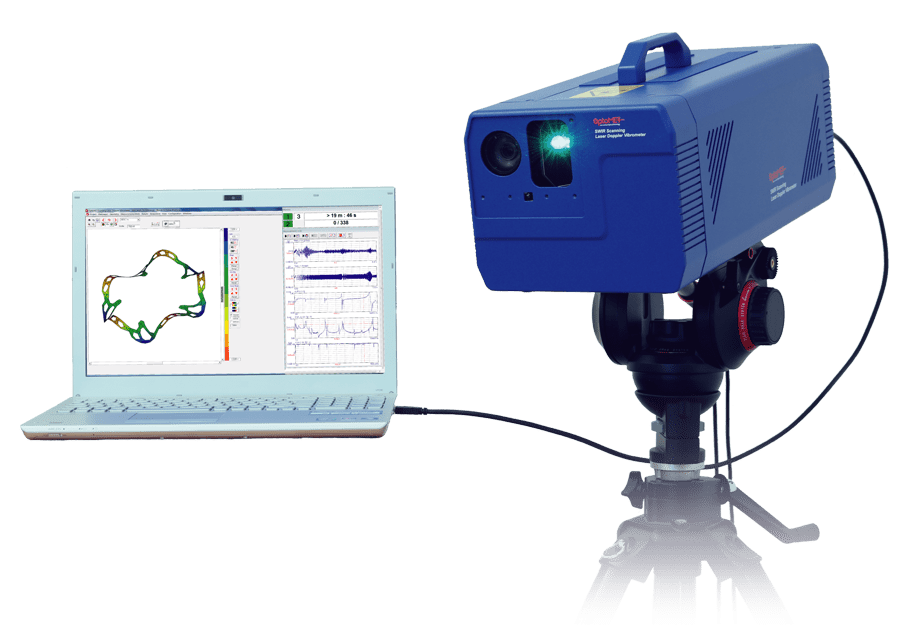

• Laser vibrometer

• Microphones

SimuTech Group engineers test and analyze the effects of blade deformation under running conditions on the performance of a highly loaded transonic mixed flow impeller.

Cyclic symmetry analysis enables the efficient assessment of full blade sets in gas or stream turbines. In the video above, our team spotlights Ansys’ software capabilities, providing a blanket overview for cyclic symmetry analysis.

Measuring the natural frequencies and mode shapes of rotating turbine blade (bucket) rows.

Determine the natural frequencies and mode shapes of a rotor train as it twists about the axis of rotation.

Identify the root cause of noise and vibration problems in machinery via ODS, spectral, order tracking or joint time frequency analysis.

Our team of experienced engineers can assist you at any step of your process.