Engineering Design Optimization

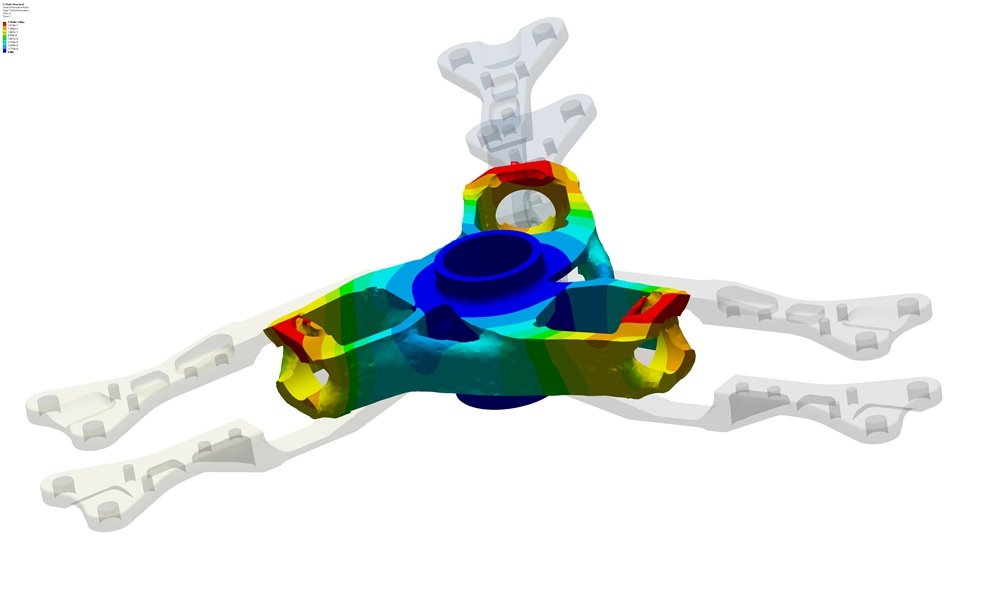

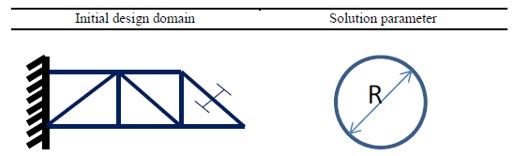

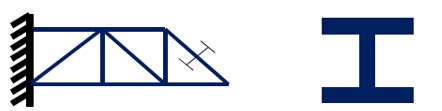

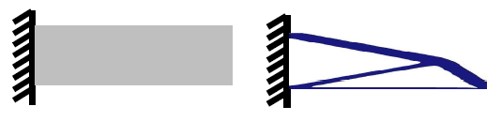

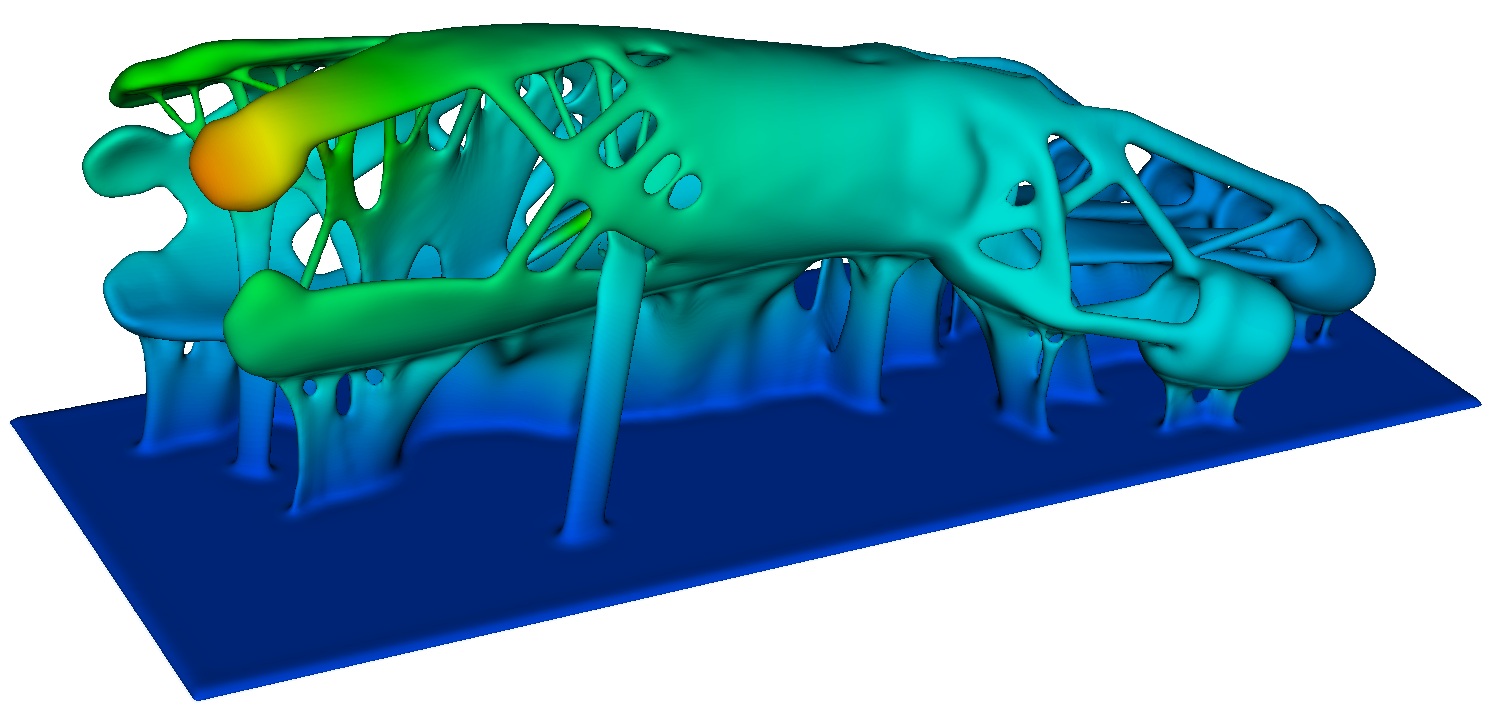

Unlock the potential of your engineering designs with SimuTech Group’s FEA optimization services. We specialize in parametric, shape, and topology optimization using advanced simulation tools from Ansys to deliver reliable, efficient solutions tailored to your needs.