Ansys Mechanical

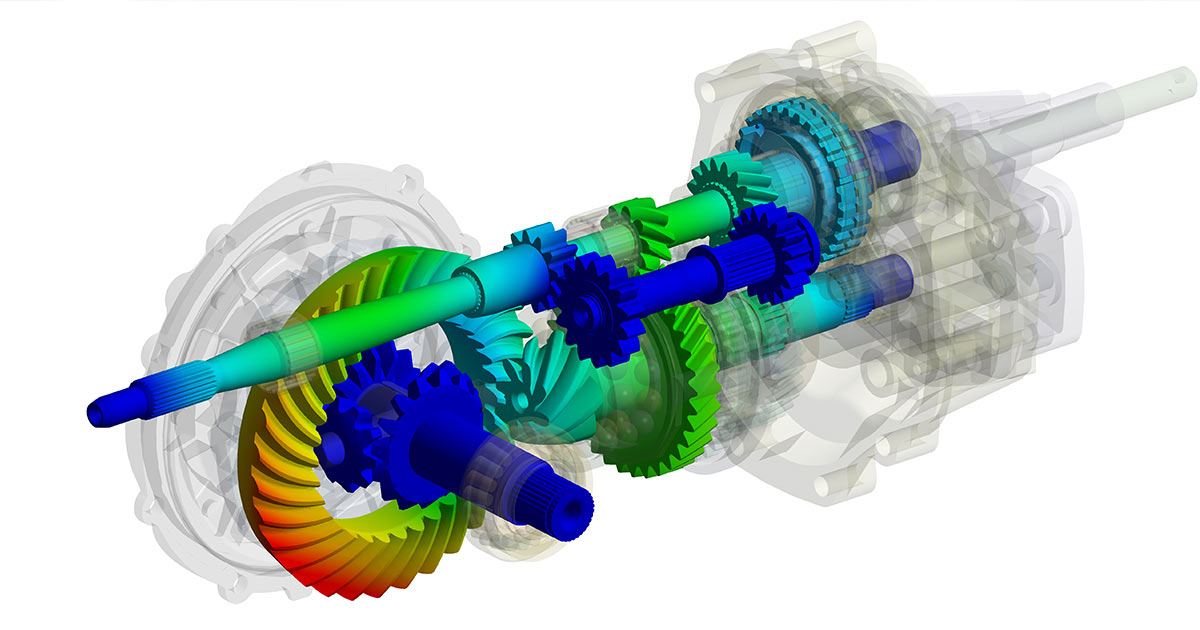

Ansys Mechanical is a best-in-class finite element solver that improves the modeling with structural, thermal, acoustics, transient, and nonlinear capabilities.

Ansys Mechanical is a best-in-class finite element solver that improves the modeling with structural, thermal, acoustics, transient, and nonlinear capabilities.

You can use Ansys Mechanical to solve complex structural engineering problems and make smarter, quicker design decisions. You can configure and automate solutions for your structural dynamics problems using the suite’s finite element analysis (FEA) solvers, and parameterize them to evaluate different design scenarios. Ansys Mechanical is a dynamic tool that has a complete range of analysis tools.

Ansys Mechanical develops an integrated framework for structural analysis that employs finite element analysis (FEA). Mechanical is a complex environment with a comprehensive set of research methods, ranging from preparing geometry for analysis to connecting additional physics for even more accuracy. Engineers of all levels can get answers quickly and confidently thanks to the intuitive and customizable user interface.

Ansys Workbench provides a secure link to commercial CAD software, allowing for design point notifications with the click of a button. Fluids and electrical solvers all have multiphysics capabilities that are seamlessly integrated.

Ansys Mechanical Key Features

Ansys Mechanical has all of your linear dynamic analysis needs covered, including modal, harmonic, continuum response, and random vibration with pre-stress, as well as advanced solver options for fast results.

Conduct acoustics simulations to better understand the vibroacoustic behavior of structures, whether or not structural pre-loading is used. Pre-loading adds fidelity and allows for the simulation of self-weighted, bolted assemblies — or even squealing brakes.

You may simulate the action of materials as they undergo plastic or even hyperlastic deformation in addition to linear, elastic materials (materials like rubber and neoprene).

Contact and significant deflection of parts moving around relative to each other, with or without friction, are also taken into account in nonlinear simulation.

Ansys Mechanical has a wide range of communication capabilities that enable you to account for the interactions between multiple components.

It can simulate anything from a bonded contact, which treats parts’ joints as if they were fused or welded together, to contact interfaces, which enable parts to move apart and together with or without friction.

Parametric, form (mesh morphing), and topology optimization are all included in Ansys Mechanical. A parametric optimization can be powered by any model in Ansys Mechanical.

A parametric optimization can be powered by any model in Ansys Mechanical. Shape and topology optimization capabilities allow efficient geometries to be created, which can then be exported to CAD for production or further simulation work. This technology has many applications, including additive manufacturing, lightweighting, and rugged construction.

Heat conduction, convection, and radiation simulations through assemblies enable you to predict component temperatures, which can then be used to investigate induced stresses and deformations.

You can read in power losses or measured temperatures from other measurement systems or files with Ansys Mechanical, which means CFD or electromagnetic simulations can be used as a starting point for thermal analysis. Fluid flow through pipes and heat produced by friction between parts can also be taken into account. All of these features allow you to run more accurate simulations and get better results.

Ansys Mechanical can accurately model a wide variety of material models, including hyperlastics, shape-memory alloys, soils, concrete, plastic, and metallic structures.

If necessary, you can also add user-defined material models. Granta Materials Data for Simulation gives you instant, clickable access to the materials property data you need, saving you time and money on data searches. Material Designer can easily create representative volume elements (RVE’s) based around lattice, fiber, weave or user-created geometries to facilitate multiscale modeling of complex material structures.

Modeling short fiber composites with data from upstream manufacturing simulation software is possible with Ansys Mechanical.

Ansys Composite PrepPost (ACP) is a dedicated modeling and failure analysis platform for composite layups. For implied and explicit structural, thermal, and fluid simulations, you can build layered composite models. ACP offers a forum with many ways to share model knowledge, as well as powerful layup and best-in-class solid element modeling capabilities. It communicates with third-party tools using the vendor-independent HDF5 composite CAE file format. Ansys Composite Cure Simulation (ACCS) simulates the curing manufacturing process in addition to modeling composite structures. It aids in the simulation of a part’s curing mechanism and the prediction of residual stresses and process-induced distortions.

Predict fluid-solid interactions accurately using pressure and/or thermal loads. Ansys has automated, easy-to-use solutions for both one-way and two-way coupling as the fluid-structure interaction grows and the problem requires more rigorous analysis.

The data is automatically transferred and mapped to the other device after the initial CFD or Ansys Mechanical simulation is solved. The fluid and structural simulations are set up and solved at the same time in a two-way coupling simulation, and data is automatically shared between two solvers to obtain stable and reliable performance.

The vast majority of research criteria associated with hydrodynamic evaluation of all forms of offshore and marine structures are addressed by Ansys.

SPARs, FPSOs, semi-submersibles, tension leg platforms, vehicles, green energy devices, and breakwaters are only a few examples. Ansys Aqwa, our product, has been used extensively in the oil and gas, renewable energy, and general engineering sectors to model equipment installation and use in open water, harbors, and sheltered locations.

The quickest and simplest way to customize the simulation workflows. Ansys Mechanical’s customization allows repetitive tasks or complex workflows to be automated and shared by users.

Journaling and scripting capabilities enable quick development and easy education of new scripts.