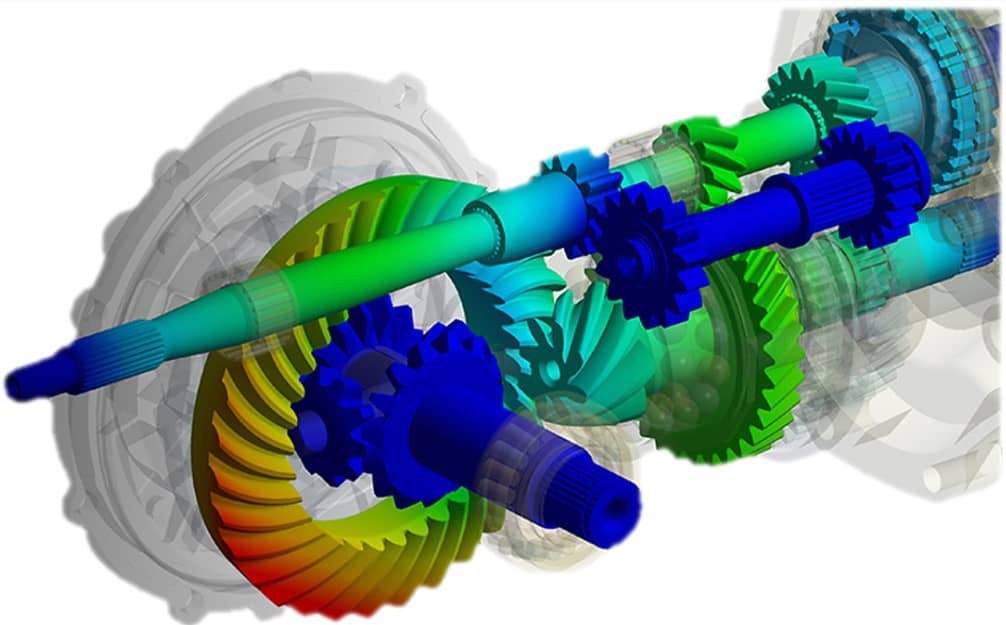

Ansys Finite Element Analysis (FEA) Software

Ansys software for structural analysis allows you to solve your most complex structural engineering projects and make superior design decisions more quickly.

Ansys software for structural analysis allows you to solve your most complex structural engineering projects and make superior design decisions more quickly.

Ansys provides software solutions for structural analysis, empowering engineers to address complex structural engineering challenges before ever building a physical prototype.

Ansys’ comprehensive suite allows engineers to conduct finite element analyses (FEA), tailor and automate solutions for structural mechanics issues, and evaluate various design scenarios. Implementing simulation software in the early stages of the design process enables businesses to cut costs, streamline design iterations, and expedite product launches.

Automate and customize your simulations, and even parameterize them for additional design scenarios.

Effortlessly manage the intricacies of diverse design environments you might encounter. The array of analytical tools empowers you to develop a product that aligns with your performance objectives and maintains durability over time.

Understanding component strength is needed to determine a product’s lifecycle, performance, and failure modes. Several factors dictate strength requirements for design and materials, including thermal stress, pressure conditions, bolt tension, mechanical loading, and fatigue.

Composite materials are versatile, strong, and light, making them suitable for manufacturing many types of products. Carbon fiber, for example, is often used in aerospace and automotive components. The use of composites is now common in applications such as musical instruments and bicycle frames. The Ansys FEA software suite allows engineers to create layered as well as fiber-reinforced composite models and verify them with various Composite Failure tools.

Simulating deformations, stresses, and possible damage due to low-speed and high-speed impact between bodies is critical in many applications. Engineers can use explicit as well as implicit dynamics technology for these types of simulations. Rigid Body Dynamics (RBD) is also available for kinematic assessment of components and assemblies.

Ansys Mechanical software helps engineers understand how their designs will respond to vibrations from rotating equipment, earthquakes, road transport, wind turbulence, acoustics, ultrasonic processes, and more. You can also determine and minimize the noise resulting from vibrations, such as brake squeal and motor hum.

To begin an analysis, engineers first simulate the performance of a base design. The model can then be re-used to examine variations in loading, design parameters, and manufacturing conditions. Response surfaces can be generated, and the design can be optimized using several available optimization algorithms.

All Ansys Mechanical solvers have been tuned to work with multiple cores on a single computer or hundreds of cores in a cluster of computers. High Performance Computing (HPC) allows engineers to model entire assemblies with the required level of detail and still get a solution in a reasonable amount of time. Productivity is greatly improved since multiple designs can be solved quickly instead of waiting for days or weeks.

Innovation continues to be driven by lighter, more efficient, and smaller designs. As that happens, heat and thermal management become more critical. Ansys Mechanical software allows engineers to perform steady state as well as transient thermal analyses that include conduction, convection, and radiation, heat transfer due to mass transport, frictional heating, thermoelectric effects, and so on.

The optimal shape of a part is often organic and counterintuitive. Ansys topology optimization technology lets engineers find these shapes simply by specifying where supports and loads are located on a volume of material. Design and manufacturing constraints can be applied, and the optimized design can be quickly verified to make sure it can withstand all loading condition.

Additive manufacturing is a method of fabricating complex parts layer-by-layer from a 3D model. Ansys additive manufacturing simulations help engineers optimize their designs for 3D printing. You can also compensate for distortions and stresses in the printed part, and predict the microstructure of the part based on the thermal history during fabrication.

To reduce the costs of warranties and improve reliability, engineers need to design durable products. Using Ansys FEA software for fatigue analysis, you can avoid unexpected failures and warranty expenses by learning how designs behave when subjected to repeated load cycles and load histories over time.

Ansys’s Rigid Body Dynamics module and Motion software allow engineers to simulate the dynamic behavior of large multibody systems. Models can include springs, dampers, bushings, and different types of joints, as well as contact between bodies. The bodies can be modeled as rigid or flexible.

Offshore structures often have specific design requirements. Ansys Aqwa provides an engineering toolset to simulate the effect of waves, currents, and wind on fixed and floating offshore and marine structures. A wide range of physical connections, such as mooring lines, fenders, and articulations can model various restraining conditions on the vessels. The analysis can also generate pressure and inertial loading for use in a structural analysis of a vessel hull.

Mechanical by Ansys is a finite element analysis (FEA) technique for analyzing complex product architectures and resolving difficult mechanical problems. In addition, you can use Ansys Mechanical to simulate real-world actions of components and subsystems.

Ansys LS-DYNA simulates the response of materials to short duration severe loading. As of 2022, it is the single most used explicit dynamics simulation program worldwide. The software is best suited for the experienced and highly technical user.

Gain quick, accurate electronic hardware life predictions with Ansys Sherlock Automated Design Analysis. In fact, Sherlock is the only PoF (Reliability Physics/Physics of Failure) software that provides insight at each the system, board, and component levels.

Ansys Motion is a third-generation engineering solution based on an advanced multibody dynamics solver. In addition, Motion enables fast and accurate analysis of rigid and flexible bodies in real-time.

Simplifying 3D Printing Part Orientation – engineers can determine the suitable orientation using heatmapping technology to orient components and specify build parameters.

Enhance ROI by Building Precision Parts – Rapidly check for distortion, stress and strain regions (static or dynamic), predict blade crash, and export for advanced post processing analysis.

Enterprise intuitively provides in-depth analyses of structural and coupled-field behavior in a highly productive, and realistic environment for optimal engineering.

Ansys Mechanical Premium is an FEA tool that gives you greater engineering insight with advanced nonlinear stress simulations and comprehensive linear dynamics.

Ansys Mechanical Pro is FEA software that provides robust general-purpose stress, thermal, vibration and fatigue simulations for fast and accurate solutions.