Ansys Sherlock

Ansys Sherlock is the only physics-based electronics design tool that can predict the existence of electronic hardware at the device, board, and system levels in early stages of development.

Ansys Sherlock is the only physics-based electronics design tool that can predict the existence of electronic hardware at the device, board, and system levels in early stages of development.

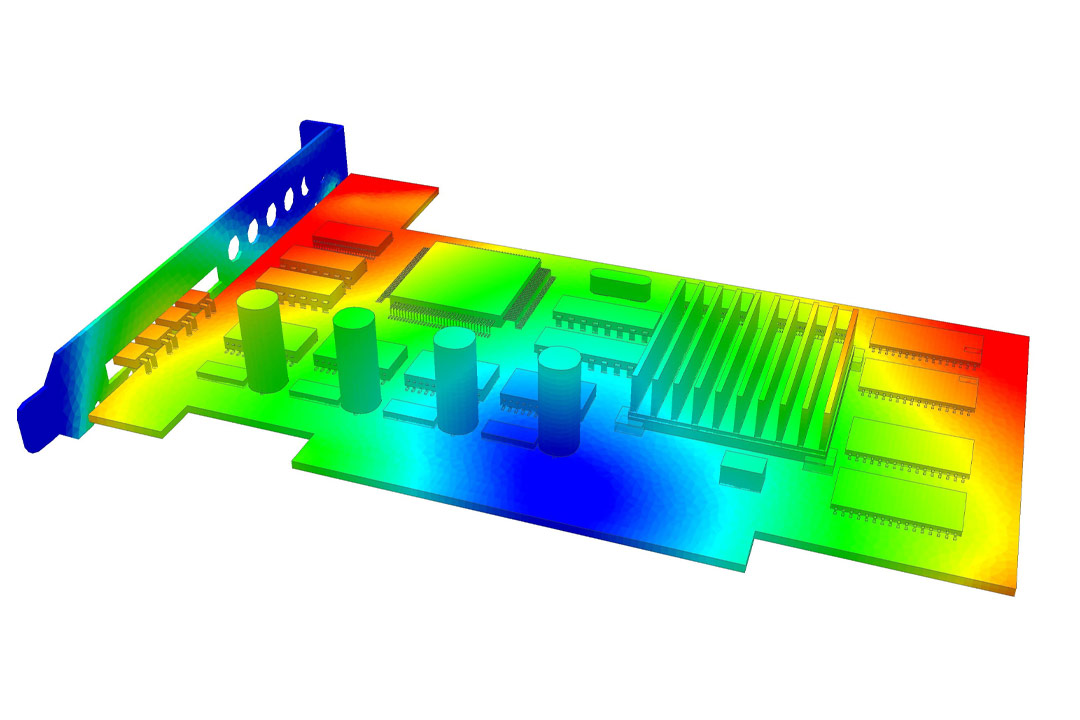

In the early stages of design, Ansys Sherlock automated design analysis offers quick and accurate life predictions. This is not merely base-level analysis for electronic hardware, but facilitation at each the component, board, and system levels. In addition, Sherlock bypasses the ‘test-fail-fix-repeat’ cycle by empowering designers to accurately model silicon.

Application types include metal layers, semiconductor packaging, printed circuit boards (PCBs) and assemblies. In fact, Sherlock will predict failure risks due to thermal, mechanical and manufacturing stressors, all before a single prototype is launched.

Electrical, mechanical, reliability engineers and more can work in tandem to implement design best practices. In effect, predicting product lifetimes and reduce failure risks.

Deploy thermal cycling, power-temperature cycling, vibration, shock, bending, thermal derating, accelerated life, natural frequency, CAF, and more. Indeed, Sherlock eliminates costly build-and-test iterations, allowing engineers to change designs in near real-time. In effect, permitting certification in just one round.

Additionally, Ansys Sherlock can forecast performance, predict thermal failure, and estimate warranty return rates. This automatic facilitation makes users more effective by directly linking simulation to material and manufacturing costs. That is, when post-processing simulation results from Icepak and Mechanical.

Ansys Sherlock Key Features

With a full and rigorous lifetime curve, Ansys Sherlock’s post-processor decides time to failure. In addition, minimizing the number of required physical testing iterations, while increasing the chances that prototypes can pass validation tests in the first round.

Ansys Sherlock gives users complete control over how they predict solder fatigue activity. The software’s completely validated 1D solder model predicts solder fatigue reliability for all electronic parts in thermomechanical and mechanical environments. Including, die attach, BGA, QFN, TSOP, chip resistor, through hole, and more.

As a function of ambient temperature, temperature rise due to power dissipation, and electrical loads, Ansys Sherlock predicts thermal failure rate. In terms of product fatigue and end of life, iterative simulations will nail-down anticipated half-life’s for multiple component technologies.

Sherlock reliably predicts the failure actions of electronic hardware and components. Moreover, using Physics of Failure and Reliability Physics techniques, supplies users with actionable findings to refine their product designs.

Sherlock, by industry standards, is the leading simulation tool for converting a range of ECAD files. More specifically, into computational-ready finite element models (FEM).

Ansys Sherlock recognizes your files and imports your parts list using its comprehensive parts and materials libraries. Including, parts, kits, materials, solders, laminates, and more. In minutes, simulative iterations create a 3D finite element analysis (FEA) model for your circuit board.

The intuitive user interface enables even novice users to add additional functionality to their PCBA model before simulation. This is just the beginning for this advanced physics-based electronic solver.