Rocky Discrete Element Modeling (DEM) Simulation Software

Simulate granular flow behavior accurately and quickly with Rocky DEM.

Simulate granular flow behavior accurately and quickly with Rocky DEM.

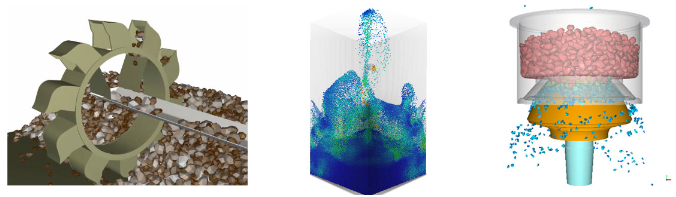

Ansys Rocky DEM, a robust 3D Discrete Element Modeling program, allows engineers to model particles with different shapes and sizes within materials handling equipment such as a conveyor chute or a mill. Ansys Rocky DEM is the industry gold-standard for particle simulation software.

Large-scale design exploration for design optimization and verification is made possible by seamless interaction with Ansys optiSLang, which also offers model calibration. Furthermore, users of Rocky can now create reduced-order models (ROMs) for their process simulations in order to develop digital twins in Ansys Twin Builder and on a range of software and hardware platforms.

In recent updates, all apps’ performance and scalability were enhanced by multi-CPU and multi-GPU. Performance studies conducted on this new edition compared it favorably to earlier versions, with improvements ranging from 50% to 1000%, depending on the type of application.

A wider variety of particle-fluid applications, as well as solutions for flows when particles are much larger than CFD mesh, are now included in the expanded CFD-DEM capability, all in a well-integrated workflow with Ansys Fluent.

More than 90% of all goods we consume were, at some point during their lifecycle, in the particulate form. Gaining insight into the manufacturing processes of particles would enable engineers to reduce waste, and improve product quality and durability. This is why having a robust particle simulation software with apposite modeling capabilities is a must-have to stay competitive in the current market.

Discover a revolutionary way to enhance mining and metallurgical processes. Compare design modifications, replicate changes to production or environmental conditions by simulating coherent flow structures, equipment, and liner wear, mixing efficiency, and more.

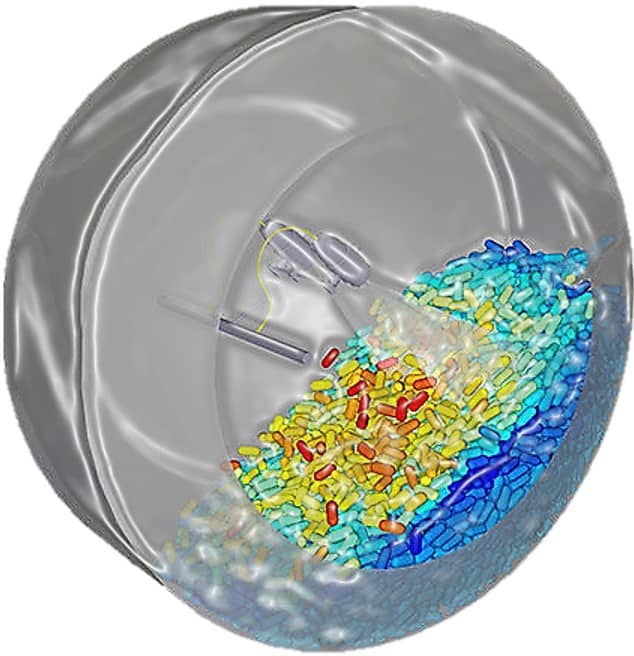

The accurate shape representation and fragmentation models found in Rocky can be used to evaluate the behavior of tablets, pills, snack chips, and more inside various kinds of screening, sorting, and mixing equipment.

Rocky DEM’s unique ability of utilizing one or more GPU cards on the same motherboard greatly speeds up the computational time and allows for large-scale simulations involving tens of millions of particles.

Rocky’s discrete element modeling uses genuine, non-spherical particle models that behave like real-world particles, which produces more realistic results.

Simulate breakage by calculating the fracture of each particle based upon the energy generated from impact or friction, direct in Rocky’s discrete element modeling interface.

Rocky DEM simulates breakage by calculating the fracture of each particle based upon the energy generated from impact or friction.

With unprecedented similarity to real-world conditions, Rocky DEM quickly and accurately simulates granular flow. Additionally, more and more mining and manufacturing organizations the world over are choosing Ansys Rocky Dem. Specifically, to analyze their bulk material handling systems.

Rocky creates variable dust-like and sticky conditions, and uses realistic shapes that behave, settle, and compact exactly like actual particles. Nearly any type of material handling environment can be replicated with Rocky.

Finally, Rocky DEM’s integration with CFD and FEA enlarges the range of industrial processes that can be modeled using DEM. Learn how companies just like yours have found solutions, resolved problems, and reached success with Rocky DEM.

Yes. Any particles modeled in Rocky DEM can have different friction coefficients, or other material properties custom-defined within Rocky.

Rocky DEM can model solids, shells, flexible fibers and more. Virtually any shape or size 3D volumetric shape which can be imported in an STL format can be used as particle for bulk modeling and particle interactions within Rocky DEM.

Yes. Rocky DEM is tightly integrated with Ansys tools and can also provide 1-way coupling to other 3rd party FEA or CFD analysis systems.

Yes. Rocky DEM has its own proprietary solver technology and can also provide fully bundled or separate Pre and Post processing capabilities.

Yes! Rocky DEM provides solving on 2 CPU cores out of box but can enable scaling to a virtually unlimited count of CPU or GPU (recommended*) cores with associated licensing.

Rocky DEM provides solving on 2 CPU cores out of box. There are also CPU and GPU “packs” for multi-core processing. Because each model and hardware/software configuration is different, we recommend talking to our sales and technical personnel.

Yes! There are a number of sample files that help get you acclimated with the GUI and workflow.

Unlimited! As much as you have time and hardware to support. The greatest limiting factor in terms of particle count is solve time, which varies with each model and hardware configuration.

Run the following procedure on each system that you have designated to be a license server.