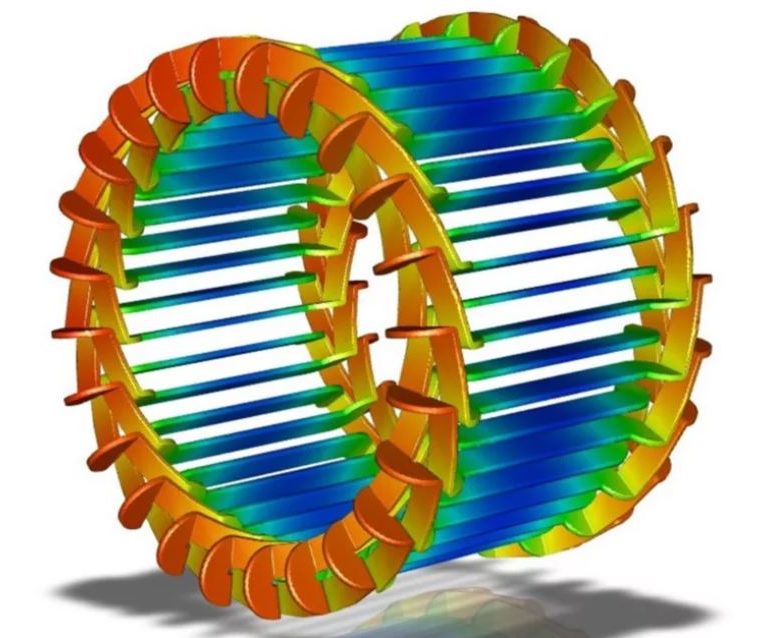

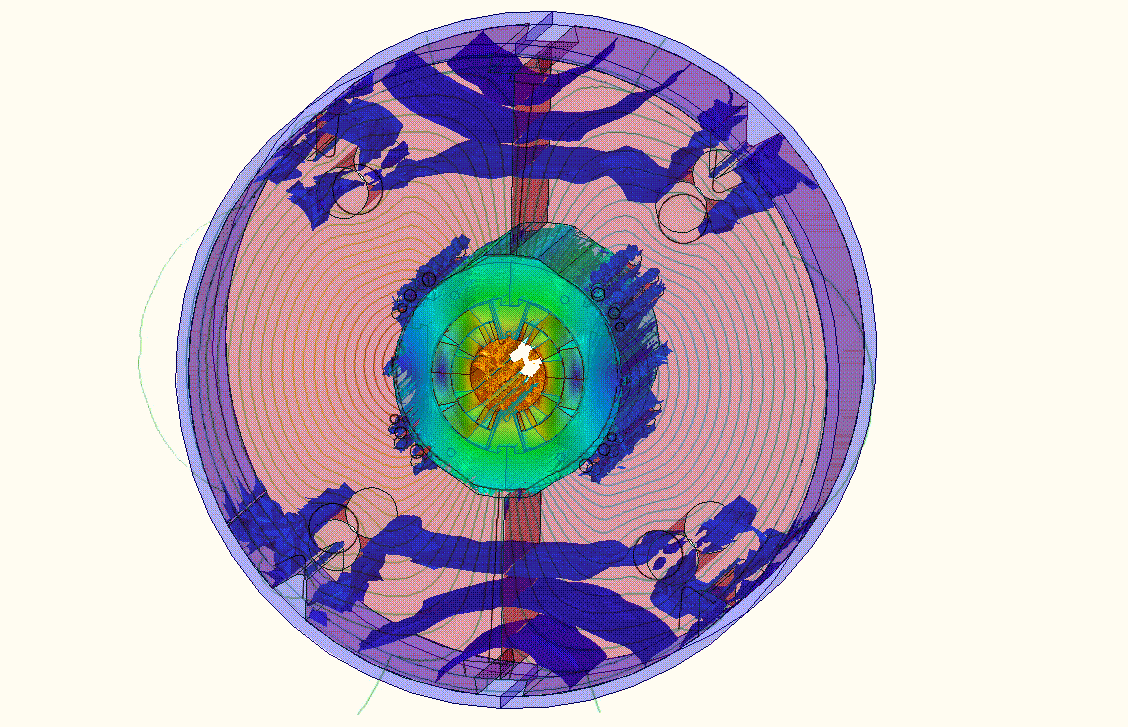

RMxprt produces geometry, motion and mechanical setup, material properties, core loss, winding and source setup for comprehensive finite element analysis in Ansys Maxwell, in addition to providing traditional motor output measurements.

The template-based interface for transformers and inductors in RMxprt can generate a configuration automatically based on voltage waveform or converter inputs. To optimize the magnetic configuration, the autodesign process considers all combinations of core shapes, sizes, materials, gaps, wire types and gauges, and winding strategies.