Ansys SIwave

SIwave models, simulates and validates high-speed channels for modern high-performance electronics.

SIwave models, simulates and validates high-speed channels for modern high-performance electronics.

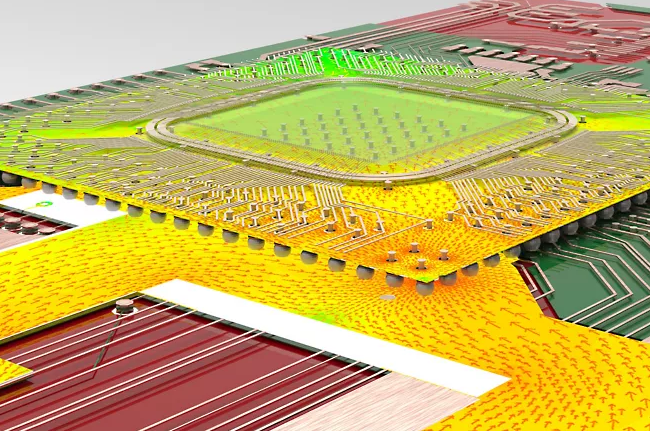

Model, simulate and evaluate high-speed channels and full power delivery systems found in modern high-performance devices with Ansys SIwave. In tandem with customized PCB signal integrity measurement settings, engineers can ensure product compliance for a variety of architectures.

Additionally, Ansys SIwave extracts multi-gigabit SERDES and memory buses with precision. SIwave’s full-wave extraction of complete power distribution networks (PDN) allows users to check noise margins, and make certain they are within acceptable limits.

Ansys SIwave dynamically links circuit and system simulations using powerful electromagnetic, thermal, and mechanical simulators. As most EEM engineering are aware, Co-analysis of power integrity, signal integrity, and thermal integrity is required for the successful design of next-generation electronic products.

Thankfully, Ansys Slwave uniquely preforms die-to-die connectivity design across ICs, packages, connectors, and boards. With shorter time to market, lower costs, and greater system performance, Slwave helps customers gain a competitive advantage.

Slwave supports a variety of extraction types. Including, signal and power RLCG IBIS for IC packaging, touch panel RLCG unit cells, bus bar RLCG, power inverter/converters. In addition, a dedicated thin-plane solution for touch panel extractions.

Automatic and configuarbale EMI deisgn rule checks are readily provided by an EMI Scanner and EMI Xplorer. Crucially, this ensures swift detection for regions of potential interference on the design prior to simulation.

Ansys Slwave offers a DDR virtual compliance package that, when used in conjunction with the DDR Wizard, delivers end-to-end virtual compliance for DDR-based designs. In addition, our new SPISim Technology makes compliance reporting for USB-C and COM calculations for IEE 802.3bj and 802.3bs channels a breeze. Moreover, customization and assistance are also possible in the programming environment. This is only the scratching the surface of Ansys SIwave capabilities and integrations.

Using DC power loss from Ansys Slwave as a heat source, this multiphysics approach provides realistic thermal modeling of IC packages and PCBs. Remarkably, Icepak overcomes the difficulties of dissipating thermal energy from electronic components. Which, if left unattended, can lead to component failure due to overheating.

After that, you can use Ansys Mechanical to calculate thermal stress. Ultimately, this multiphysics technique enables you to do a linked EM-thermal-stress analysis before production to gain a thorough understanding of the design.

Ansys HFSS simulates 3-D full-wave electromagnetic fields for accurate and rapid design of high-frequency and high-speed electronic components.

Ansys Maxwell simulates 2-D and 3-D low frequency electromagnetic fields for accurate and rapid design of electromagnetic and electromechanical devices.

Ansys Icepak provides electronic cooling solutions that utilize the industry leading CFD solver for T&F flow analyses of integrated circuits, PCBs and electronics.

Ansys SIwave is a specialized design platform for power integrity, signal integrity and EMI analysis of electronic packages and PCBs.

Ansys Q3D Extractor provides 2-D and 3-D parasitic extraction for engineers designing electronic packaging and power electronics.

Electronics Desktop is a unified platform for electromagnetic, circuit and system simulation. Free download available for students!

Nuhertz FilterSolutions provides automated RF, microwave and digital filter design, synthesis and optimization in an efficient, intuitive process.

Ansys Motor-CAD is a specialized electric machine design tool that allows for quick multiphysics simulation over the entire torque-speed working range.

Delivers simulations of cloud-to-ground lightning strikes, high-intensity radiated fields & emissions, EM pulses, EMI/EMC, crosstalk and more.