Expedite your Blade Design to CAD Process.

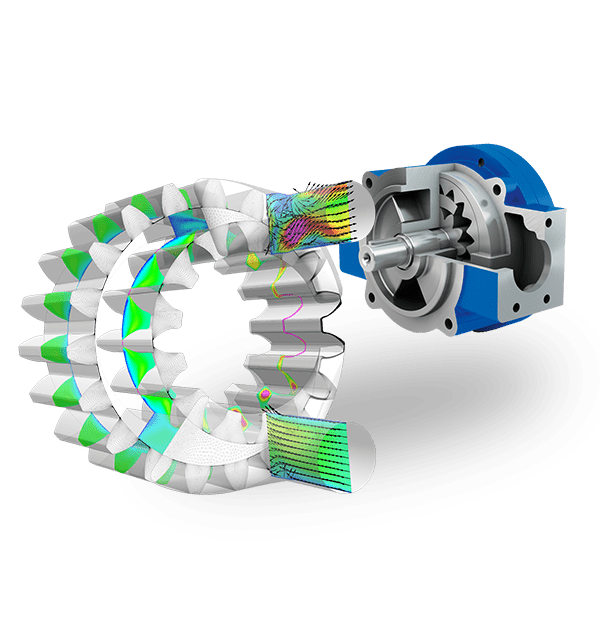

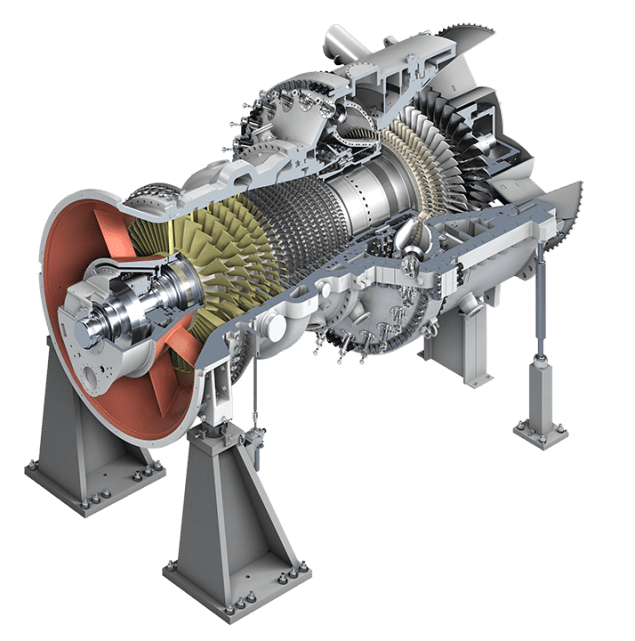

Our Blade modeling software empowers engineers through all phases of the design stage, and renders superior versatility – accommodating all varieties of rotating machinery. The software delivers complete 3D geometry modeling control and even allows for non-bladed equipment to be imported from other CAD software (and all major CAD vendors are compatible).

3D Blade Modeling Software |

Importing CAD Blade Geometry

Full Blade Modeling Design Control and Analysis

- Ansys BladeModeler is fully integrated into the Workbench platform to provide engineers with powerful options for defining the workflow and connecting to different applications in your design process with simple drag-and-drop actions.

- The user-friendly program allows you to directly transfer designs to throughflow analysis using Ansys Vista TF or to mesh generation with the Ansys TurboGrid tool.

- Once the 3-D geometry is optimized, you’ll have the freedom to calculate an inviscid equation of motion and full 3-D flow simulation all within the same gas turbine blade design program software.

- Keeping all these features warehoused in the same place allows you to quickly analyze and tweak your design, making the overall process much quicker and efficient.

Ansys Modélisateur de Lame ➢ Optimisation de la Conception de Votre Billet à la Lame

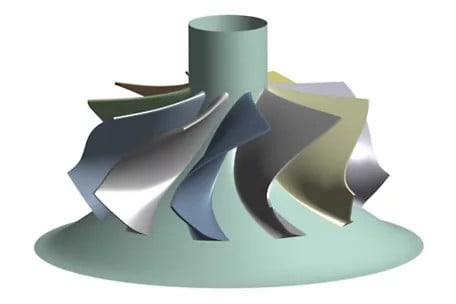

Start with a few of your own defined parameters (pressure ratio, mass flow rotational speed, gas properties, geometric constraints) and the software will calculate a 3-D blade geometry and calculates aerodynamic performance parameters. It will also provide you with a meridional view of the impeller.

- Computations consider 1D in-line analytical model for centrifugal compressors with variable inlet guide vanes

- Simulated 1D models are developed to predict the effect of varying the inlet guide vane angle at different rotational speeds

- Iterative algorithms embedded within software, providing a fast and efficient method for evaluating the performance of the compressor under different operating conditions

How are centrifugal compressors and pumps used in industrial applications?

Centrifugal compressors and pumps are universally used in a range of industrial applications like refrigeration and air conditioning, turbo-machinery, power generation, and turbochargers. While a compressor can be designed with a specific operating condition in mind, it is often imperative to run the compressor over a wide flow range. As a result, off-design performance and efficiency are often an essential consideration. The mass flow rate, and subsequently the pressure change across the compressor, can be maintained by adjusting the rotational velocity of the impellers. Yet, this may not be efficient, especially if frequent adjustments are needed. An alternative approach is the application of Inlet Guide Vanes (IGVs). A positive vane angle generates preswirl in the direction of impeller rotation and, therefore, diminishes compressor work at a provided revolutions-per-minute (RPM).

- Ansys BladeModeler uses the turbo-designer language to help make complex 3D blade geometries. Allowing users to control blade angles and thickness on 2D span-wise layers.

- Blademodeler’s database readily describes the functional design of a high-level language architecture directed towards the execution of programs written in Turbo-designer language (among others), with the ideas being applied to other block-structured languages in general.

- In fact, Blademodeler’s language processor does not necessitate complex software of compilers, assemblers, and linkage editors in order to run Turbo Pascal source code programs. The language processor can execute Turbo Pascal programs numerous orders of magnitude faster than conventional systems without specified language orientation.

- The Blademodeler language processor closely reflects the data and control constructs of the high-level language. The language processor is crafted as a pipelined processor in which several dedicated hardware processors are operating simultaneously. Other innovations in Blademodeler’s language processor are also described, making greater use of current developments in Very Large Scale Integration (VLSI) technology.

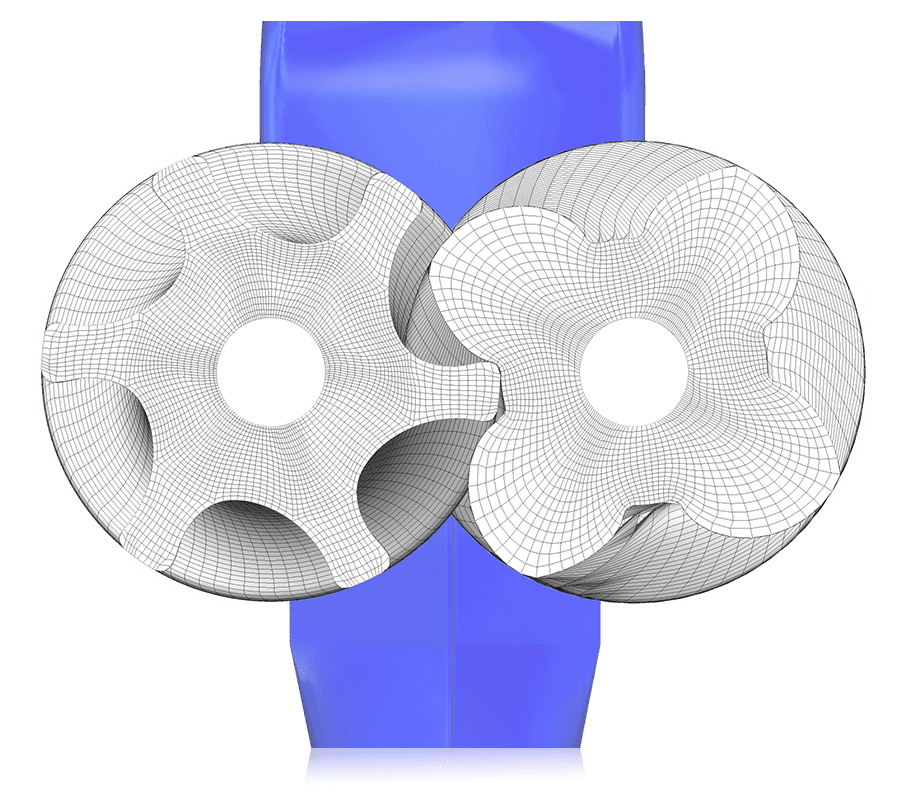

- Flank milling operations are particularly common in aerospace industry, especially when milling impellers and blades of the gas turbines.

- The fundamental operations are usually conducted on three-, four- and five-axis machine tools depending on the complexity of the airfoils to be machined.

- The part is modeled and multi-axis NC tool path is generated in CAD environment. However, traditional machining process physics is not considered in selecting feeds, speeds and depth of cuts during NC tool path generation step. Blademodeler solves this oversight through integrative capabilities.

- The software seamlessly present unique solution (based on industry) that integrates process simulation and optimization to flank milling operations conducted with tapered helical ball end mills.

- Majority of the past research in flank milling has been dedicated to modeling of the ruled surface which can be machined in flank milling mode. Ansys Blademodeler trailblazes where most researchers left off.

- Ansys BladeModeler allows you to easily import other non-blade components from all major third-party CAD vendors.

- All components such as hub metal, blade fillets and cutoffs can be also be defined within the software. From there they can be quickly exported and ready for simulation.

- Ansys Workbench integration allows you to streamline your turbomachinery workflow from blade design all the way to post-processing and design exploration and parametric studies.

- One of Blademodeler’s main objectives of efficient modern gas turbine engine design is to reduce secondary flow loss at any stage.

- Normally, the gas turbine has a higher end-wall angle design to achieve high-efficiency execution.

- The high endwall angle is devised to reduce the large deflection angle of the blade profile and meet the constraints of the expansion ratio.

- Due to the large expansion angle, the end-wall boundary layer splits early, resulting in a large secondary flow loss. At the same time, the thermal load of the endwall is impacted by the secondary flow and becomes more complex.

- Various studies on this topic have shown that fillet structure plays an important role in reducing secondary flow loss. However, few software’s have been optimized specifically for Fillet Characteristics.

- Our team understands the significant value to build software accommodating the influence of fillet structure on the flow and heat transfer characteristics of the large meridional expansion turbine stators.