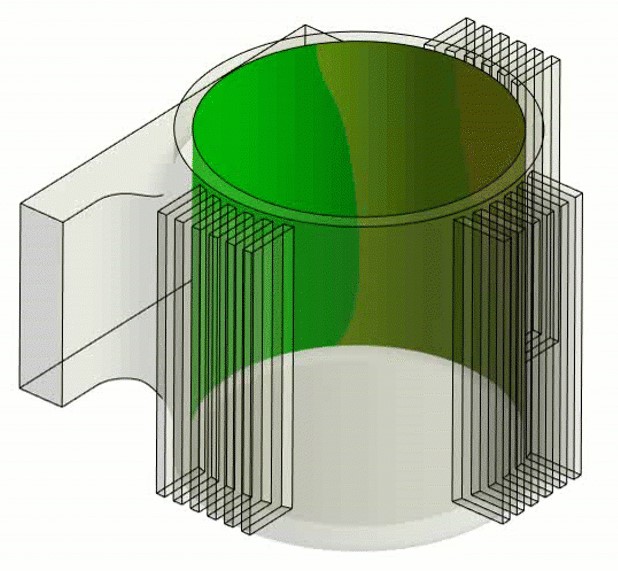

CFD Simulation of Mixing Tank Process

In manufacturing settings, a mixing tank is often used to prepare materials for production. Large amounts of materials are put into an enormous tank in order to blend components together through a refined CFD Mixing Tank, which can be measured in Ansys software.

Mixing tanks are an important piece of equipment in industries such as:

- Water/Effluent Treatment

- Pharma/Bio-Tech

- Biofuels

- Cosmetics

- Oil & Petroleum

- Mineral Processing

- Flue Gas Desulpherization

- Paints & Coatings

- Adhesives & Sealants

- Polymer & Plastics

- Mining

- Chemical Processing

Manufacturing Variables | Effects on Speed, Temperature, Quality

The $64,000 question for the manufacturer: Do the quality and consistency of the final mixture meet the intended goals? If not, what needs to change? Obviously, the manufacturer can adjust the material inputs, the speed of the mixer, and other factors through trial and error. However, this approach provides information only on the inputs and outputs. If I add so much of product A and so much of product B, and mix at a certain speed for a certain time and at a certain temperature, then I get product C. This method doesn’t offer much information on the actual mixing process itself.

Simulation in CFD Mixing Tanks

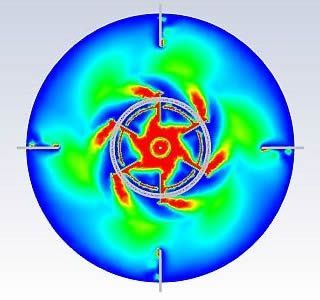

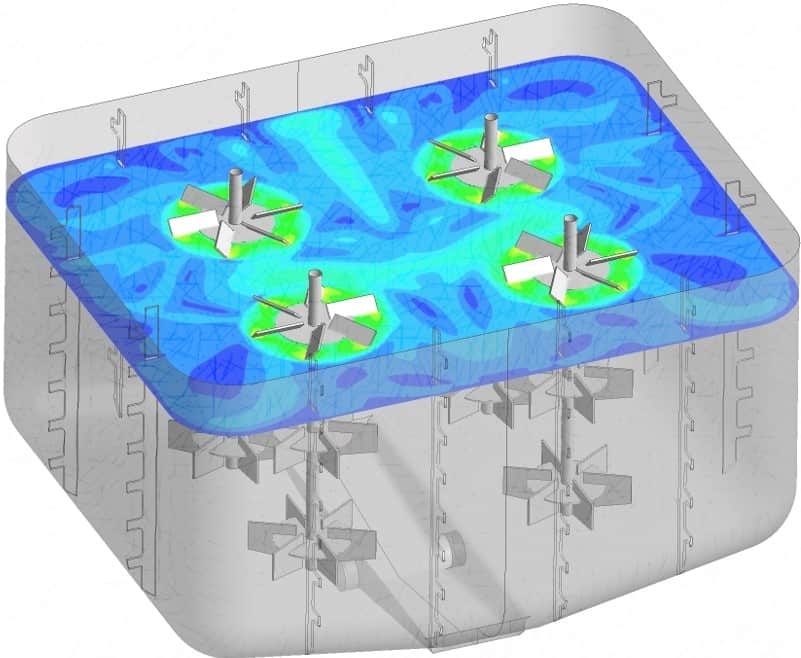

Computational Fluid Dynamic (CFD) simulation software can provide much more insight into the mixing process, showing the manufacturer a detailed picture of what is happening inside the tank and how the materials are reacting over time. For example, what if the mixing process could be shortened by 30 seconds? What kind of economic impact would that make?

To demonstrate how Ansys CFD works powerfully in these situations, we recently hosted a one-hour webinar, “Modeling Mixing Tanks Using Ansys CFD.” This webinar covers setting up a mixing vessel simulation in Ansys CFD and discusses rotating components and their interaction with stationary components. Specifically, rotating and stationary domains and their interfaces are explored in depth. There is also a discussion of multiple phases and changing material properties during the mixing process.

Watch this webinar: Modeling Mixing Tanks Using Ansys CFD

Also, there is a helpful Ansys CFD App – Mixing Guided Process Template that provides easy-to-use and automated workflow for creating mixing tank geometry, running single phase (flow blend and exposure analysis) simulations and generating comprehensive mixing report.

Expert CFD Consulting

Our CFD engineers can assist you with any of your mixing tank simulations. Contact us today at (800) 566-9190 or info@simutechgroup.com to discuss your needs in modeling all types of mixing vessels.