Selecting the Correct Strain Gauge for Testing

Strain Gauge selection may appear to be a simple task with little significance for the stress analysis, but this is far from the case.

Strain Gauge selection may appear to be a simple task with little significance for the stress analysis, but this is far from the case.

The selection of the proper strain gage for the task is the first step in preparation for any strain gage installation. At first glance, gage selection may appear to be a simple task with little significance for the stress analyst; yet, in practical application, this is far from the case.

Optimizing gage performance for specified environmental and operating conditions, obtaining accurate and reliable strain measurements, contributing to ease of installation, and minimizing the total cost of gage installation. Indeed, all these benefits can spawn from careful, rational selection of gage characteristics and parameters.

The following parameters, which are configurable to varied degrees, determine the installation and operating characteristics of a strain gage:

Essentially, the gage selection procedure is identifying the specific available combination of parameters that is most compatible with the environmental and other operating circumstances while also meeting the installation and operational limits. These restrictions are typically expressed as requirements such as:

The cost of the strain gage is usually not a major factor in gage selection because the most important economic factor is the total cost of the entire installation, of which the gage cost is usually only a minor part. In many circumstances, choosing a gage series or an optional feature that raises the gage cost actually lowers the overall installation cost.

It’s important to remember that gage selection is usually a compromise approach. This is due to the fact that parameter selections that tend to meet one constraint or requirement may work against satisfying others. In the instance of a small-radius fillet, where gage installation space is restricted and the strain gradient is exceptionally high, one of the shortest possible gages might be the apparent choice.

At the same time, gages with a length of less than 0.125 in (3 mm) have a lower maximum elongation, a shorter fatigue life, less steady behavior, and are more difficult to install. The stock of gages on hand for day-to-day strain measurements is another factor that might influence gage selection and lead to compromise.

The parameters for strain gage selection discussed here are mostly for stress analysis applications. While many of the selection criteria for strain gages used on transducer spring elements are similar to those described here, they can differ greatly from application to application and should be handled as such.

Need help determining which Strain Gage your business should be working with? This is something that the SimuTech Group Mechanical Testing Engineers can help with.

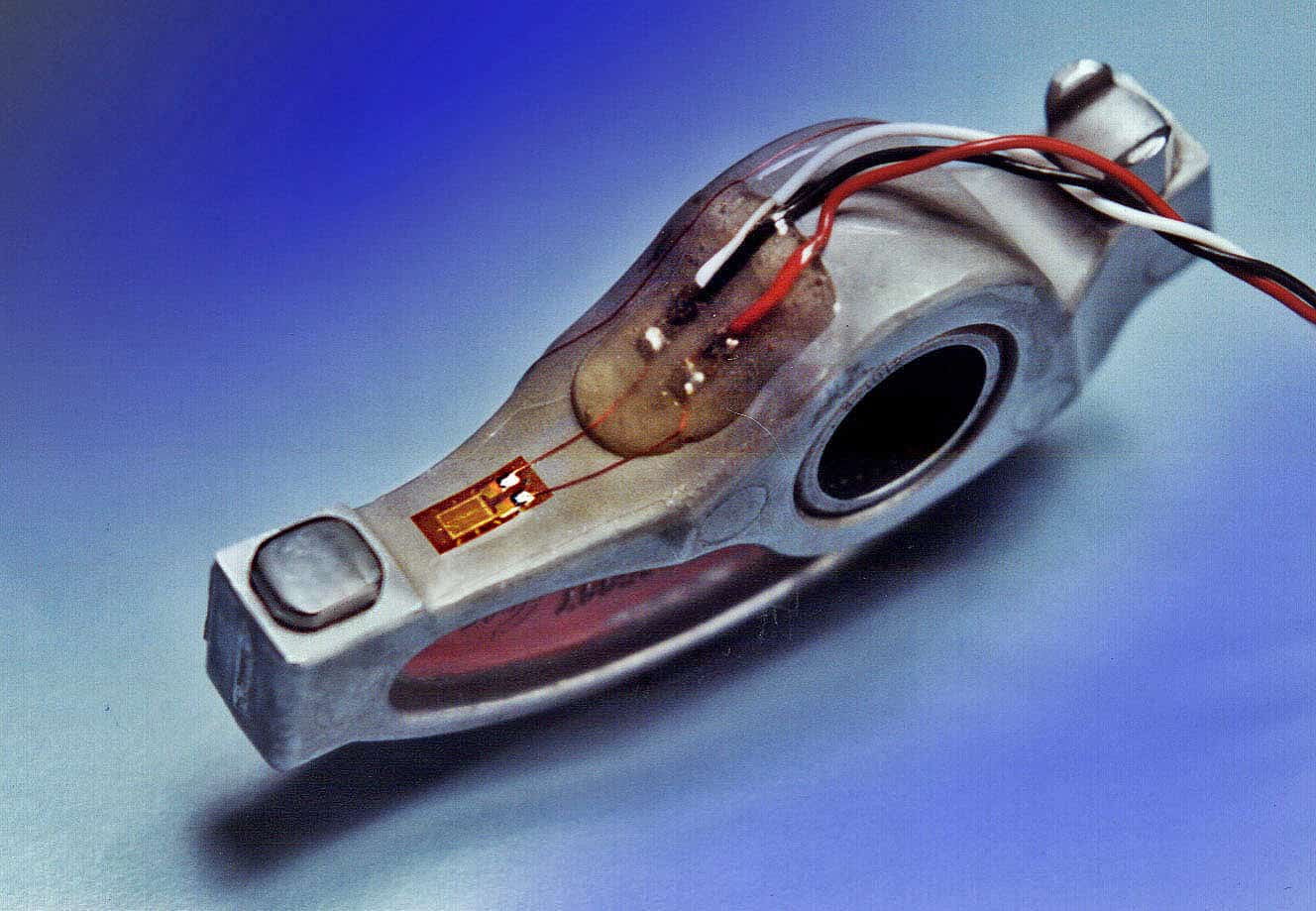

Strain gauges are ideal for verifying stress and displacement simulation models. The strain measurements are taken at specific locations and correlated with the simulation results.

Modeling assumptions such as boundary conditions, contacts, and loads may be updated to make the simulation better fit the observed behavior.

Once the model accurately reflects the measurements, more detailed information about the system can be inferred.

In addition, simulations of the modified system can be used to predict behavior with confidence.

SimuTech Group specializes in both strain gage measurement as well as simulation, allowing seamless support when conducting investigations.

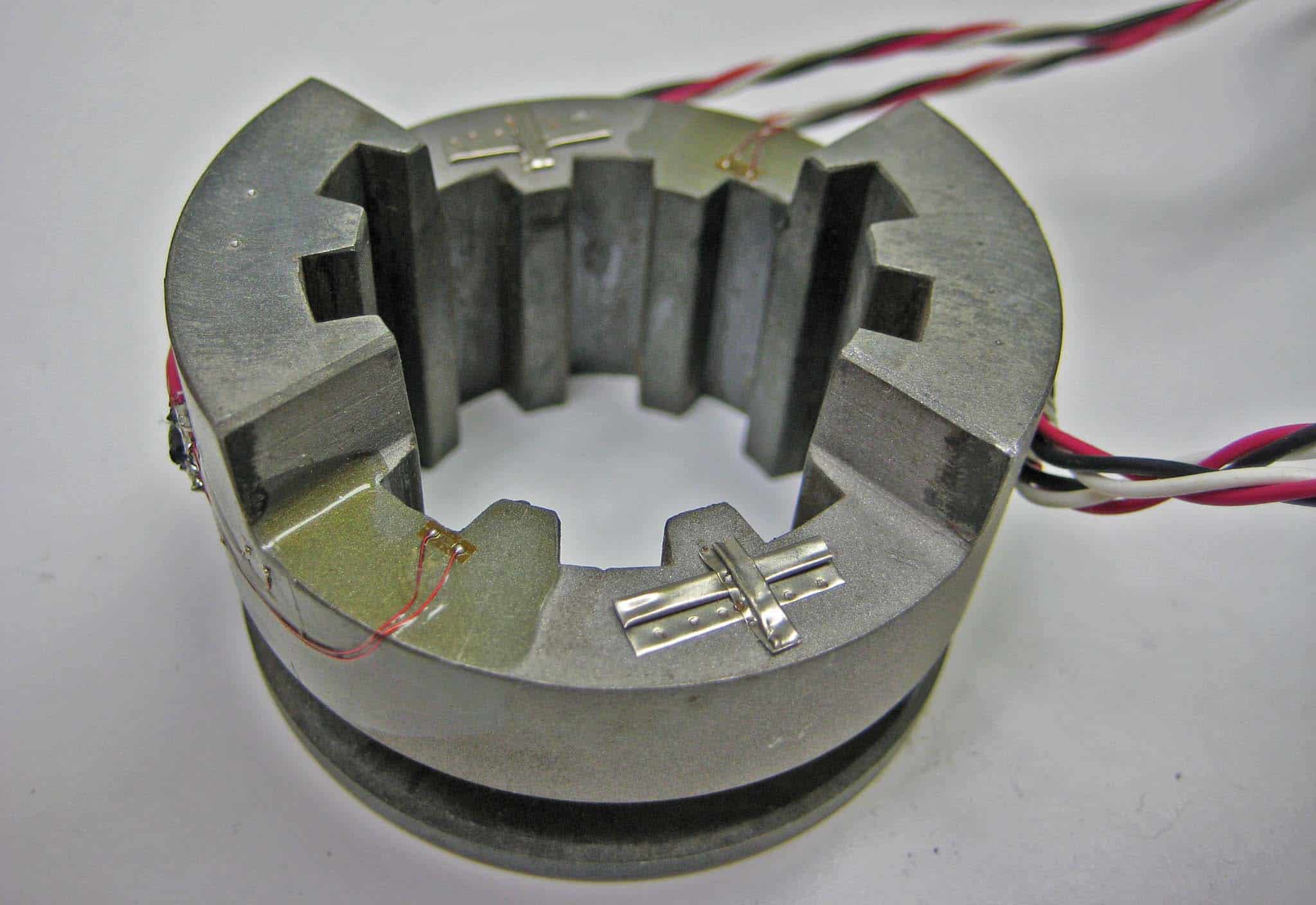

For new, refurbished, or reverse engineered turbine blades (buckets) to ensure that natural frequencies are within specifications.

Determine the natural frequencies and mode shapes of a rotor train as it twists about the axis of rotation.

Identify the root cause of noise and vibration problems in machinery via ODS, spectral, order tracking or joint time frequency analysis.