Vibration diagnostics are used to identify the root cause of noise and vibration problems in machinery.

In standard vibration diagnostics testing, techniques such as these are used to detect abnormal vibration characteristics.

These techniques are applicable to a broad range of vibration related problems such as:

Knowledge gained from our vibration analysis services leads to practical solutions including:

Recent vibration diagnostics applications include:

SimuTech Group’s expertise in advanced vibration measurements and services has gained recognition across North America due to our quality of analysis and commitment to precision, allowing businesses to approach their engineering problems with confidence.

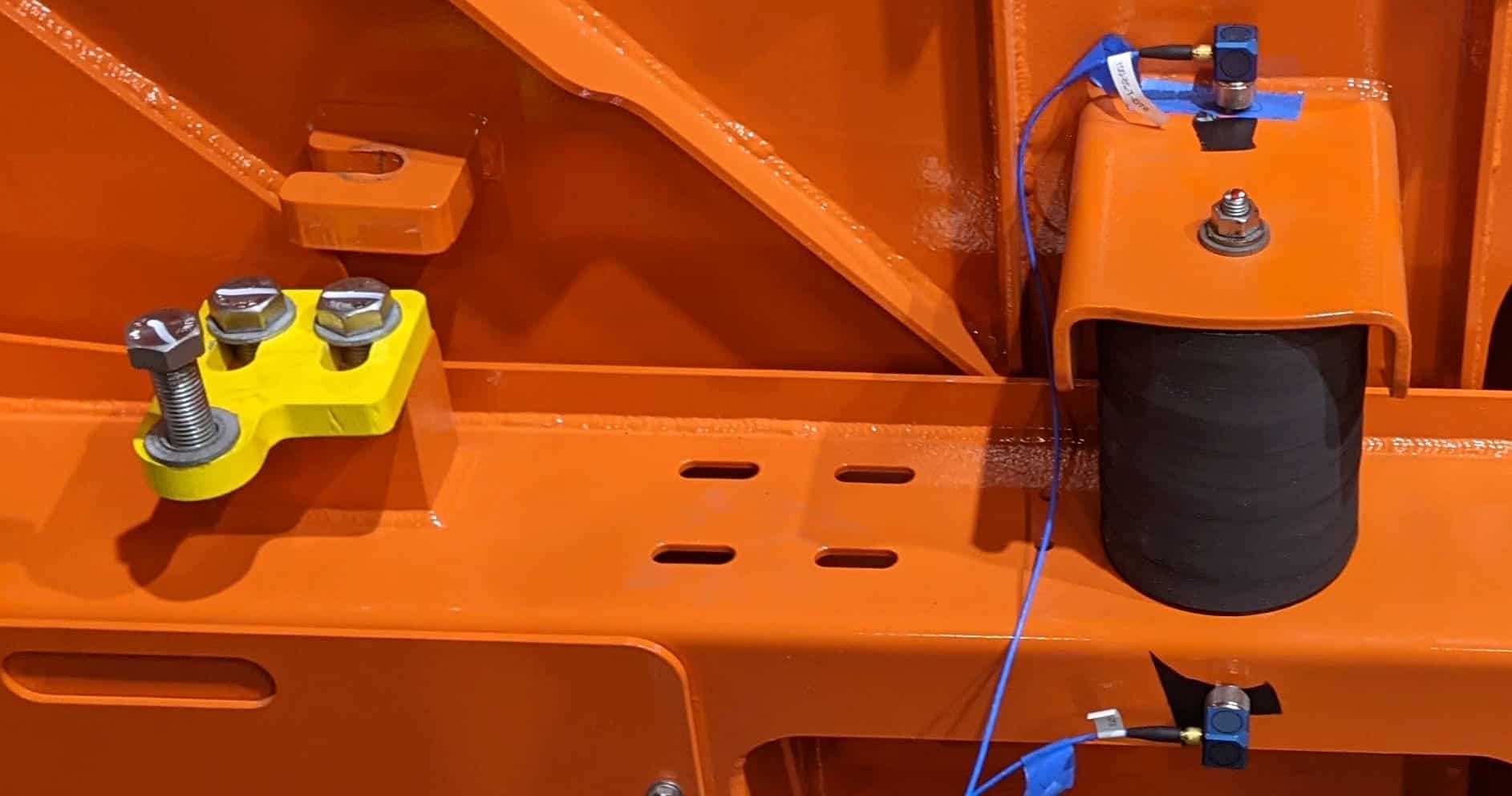

Advanced techniques for testing includes modal testing (rap testing or bump testing), operating deflection shape (ODS) analysis, strain gage measurements, spectrum (signature) analysis, order tracking, joint time frequency (waterfall) analysis, demodulation and finite element analysis (FEA).

These capabilities plus state-of-the-art equipment, enables SimuTech to diagnose the root cause of noise and vibration problems.

Based on a clear understanding of the problem, SimuTech Group provides practical solutions including specification of isolation systems, tuned mass dampers, surface damping treatments, shaft balance and alignment procedures, excitation source control, repair procedures, natural frequency detuning, and active vibration control.

SimuTech Group’s vibration diagnostics and troubleshooting services offer advanced techniques at competitive prices with an emphasis on communication and customer service.

Noise and vibration testing is extremely flexible in application and can be used in almost any field with a dynamic system. NV testing can be performed without causing alteration or damage to the structure while being sensitive to design, manufacture, and operation.

Below is a non-exhaustive list of examples:

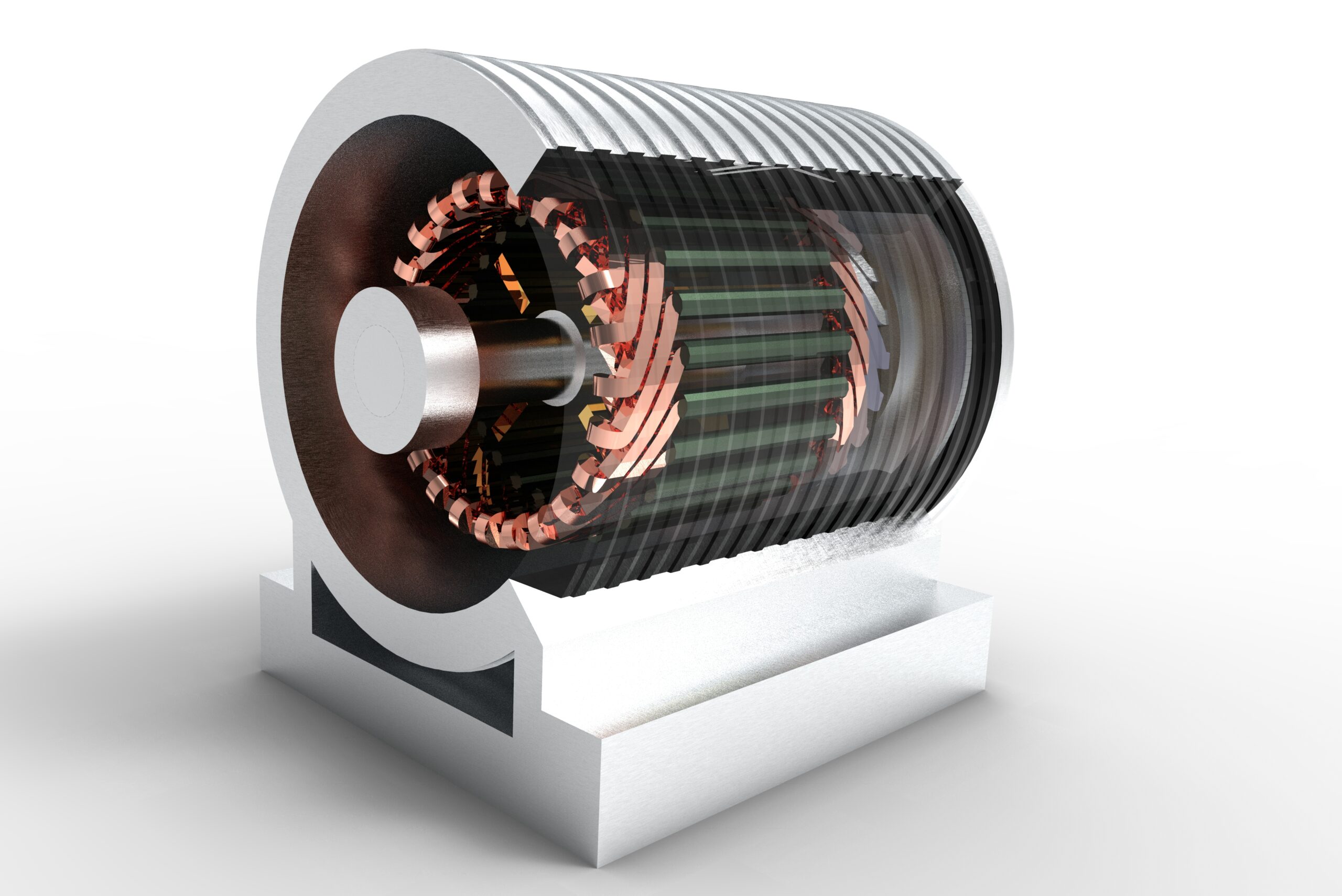

Measure and analyze blade weight and the COG location to determine the optimum blade stacking position.

Determine the natural frequencies and mode shapes of a rotor train as it twists about the axis of rotation.

For new, refurbished, or reverse engineered turbine blades (buckets) to ensure that natural frequencies are within specifications.