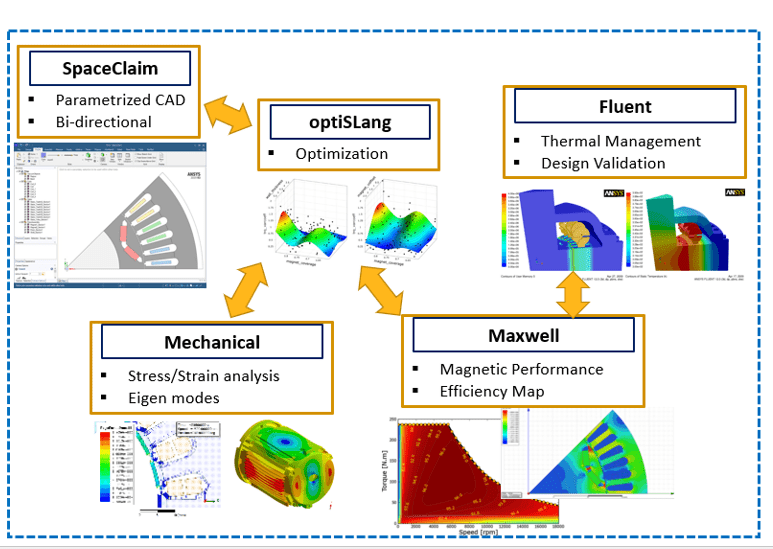

Turbomachinery design is increasingly carried out by means of automated workflows based on high-fidelity physical models and optimization algorithms concurrent in geometry parametrization.

Currently, parametrization methods used for this purpose are often tailored to one particular type of turbomachinery blade, and do not provide shape derivatives required for gradient-based optimization.

Additionally, these methods are not suited to re-parametrize a baseline blade geometry defined by a set of scattered point coordinates in a systematic way.

Here, this research presents a general blade parametrization method for axial, radial, and mixed flow blades based on typical turbomachinery design variables, along with NURBS curves and surfaces.

The shape derivatives are computed by means of the complex-step method, allowing the integration of the parametrization into gradient-based shape optimization workflows.

In addition, the method permits the re-parametrization of a blade geometry defined by a cloud of points by solving a two-step optimization problem. The capabilities of the method are demonstrated by replicating eight blade geometries in two and three dimensions with an accuracy comparable to the tolerances of current manufacturing technologies.

Multi-Objective Optimization |

Mixed Flow Impeller

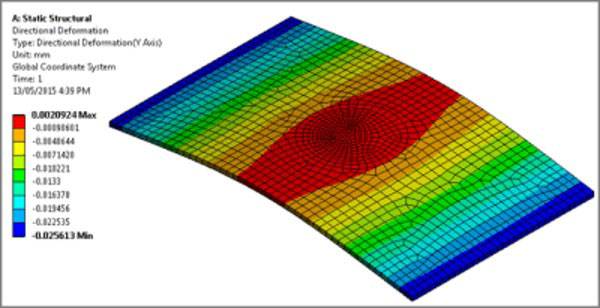

SimuTech Group engineers test and analyze the effects of blade deformation under running conditions on the performance of a highly loaded transonic mixed flow impeller.

Analyse de Symétrie Cyclique |

Assemblage de la Lame de Ventilateur

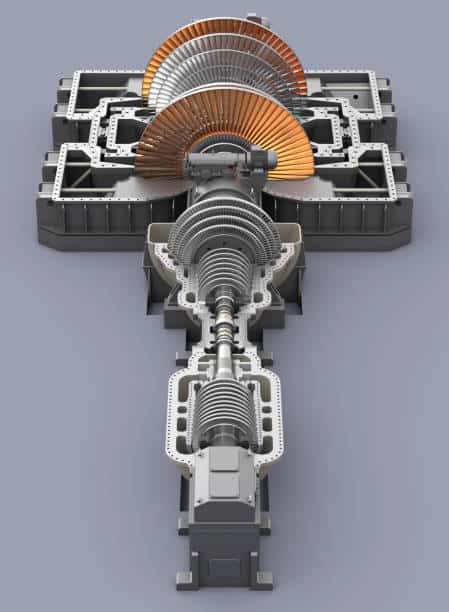

Cyclic symmetry analysis enables the efficient assessment of full blade sets in gas or stream turbines. In the video above, our team spotlights Ansys' software capabilities, providing a blanket overview for cyclic symmetry analysis.