Nanofluids in the 21st Century

Introduction | Applications of Nanofluids

Power requirements for electronic mechanisms have risen steadily in recent years, with the rate of expansion sloping upwards, and that has necessitated enhanced thermal management solutions to preserve performance and maintain the mean time between failures of these mechanisms.

There are a range of solutions that can be implemented for cooling high power electronic mechanisms from air to liquid cooling. While air cooling is the default, liquid cooling is necessary when high-power electronic mechanisms dissipate to a greater extent than of 300-525 W/cm2. The addition of nanoparticles to a coolant (i.e. Nanofluid) is another alternative that can provide additional improvement within a liquid cooled apparatus.

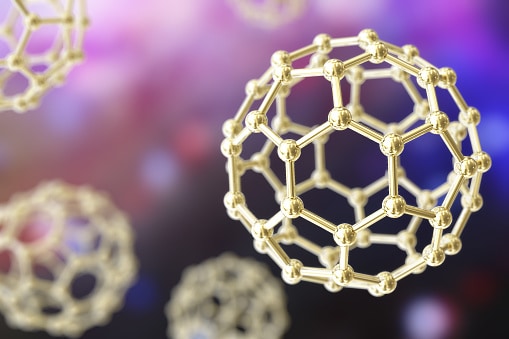

Engineered suspensions of nanoparticles in fluids have become known recently as nanofluids. The nanoparticles dispersed in a base fluid are typically metal or metal oxide particles with a dimension range of 1-100 nanometers.

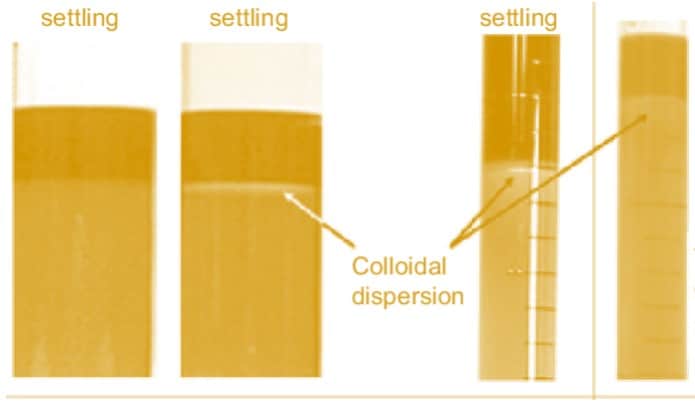

When suspended in the base fluid, nanoparticles create a colloidal solution that has been shown to eliminate the issues of erosion, sedimentation and clogging that plagued earlier solid-liquid mixtures that used larger particles.

Dispersion of nanoparticles in a base fluid alters the fluid’s overall thermo-physical properties (such as enhancing the thermal conductivity). Researchers were able to demonstrate as much as 20% enhancement in heat transfer performance of the single juncture, liquid cooled apparatus when nanoparticles were announced.

This report/analysis tries to offer a basic overview of nanoparticles and nanofluids for engineers unfamiliar with this topic, including a basic introduction of what nanofluids are, terminology and selecting criteria for engineers, price points, market trends, basic applications, challenges and suppositions. The conclusion of this report contains both a definition of terms for this topic and a list of recommendations for resources.

.

Nanofluid Structure | Basic Composition

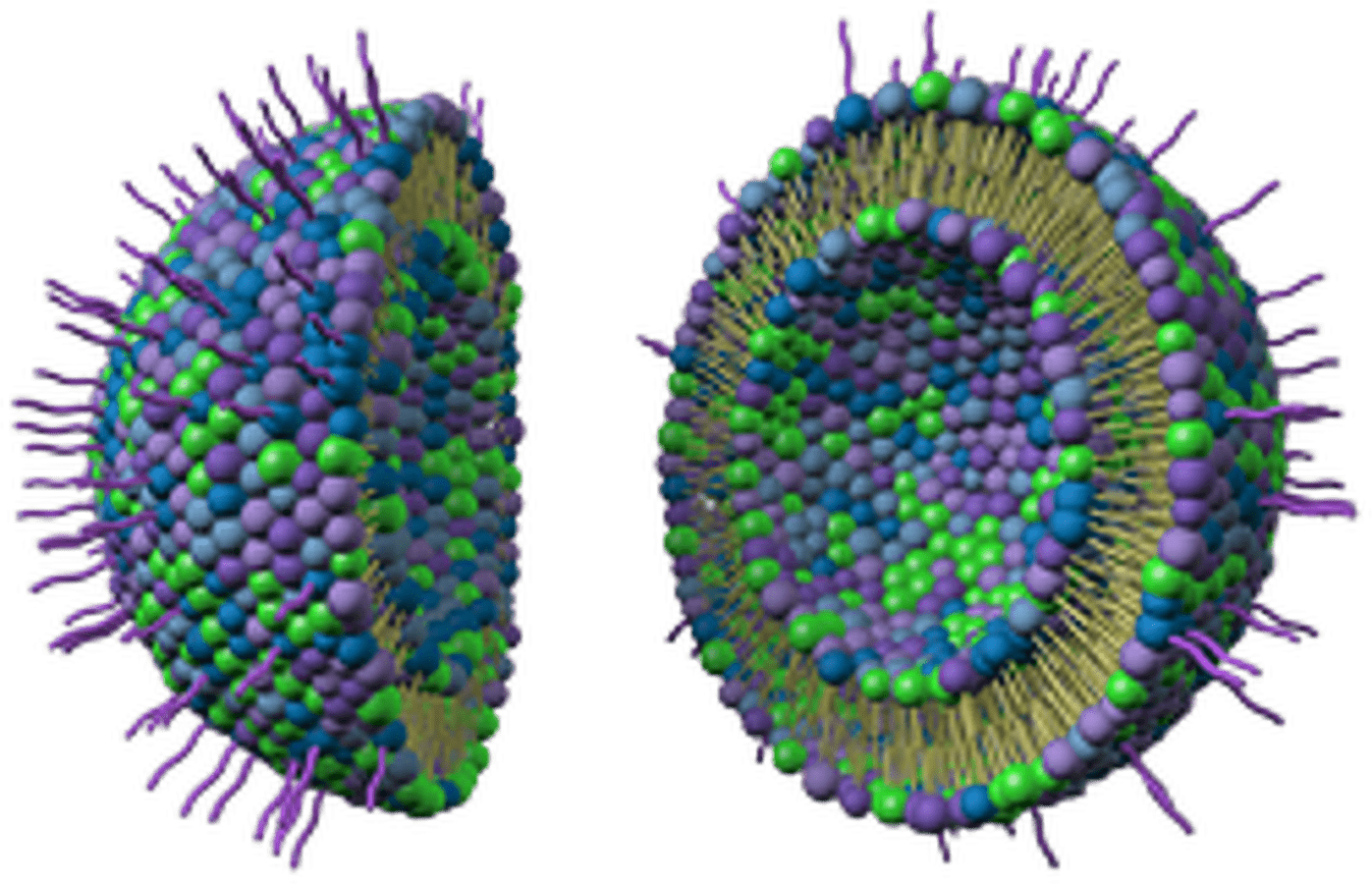

Nanofluids are made up of two basic components: nanoparticles and a base fluid. Surfactant is also used in some cases to expansion colloidal stability.

The nanoparticles used in nanofluids are typically metals, metal oxides, carbides, or carbon nanotubes. Common base fluids include water, ethylene glycol and oil. The mixture of nanoparticles into a base fluid creates a colloid, as shown in the figure below.

The addition of nanoparticles to a base fluid enhances thermal conductivity and viscosity of the resultant nanofluids. The degree of enhancement depends on various factors such as volume fraction of the particles being added, particle shape, etc. The reasons for the enhancement are attributed to several microscopic phenomena including particle dynamic effect, liquid layering on the surface of the nanoparticles, and particle clustering.

Relevant Industries and Practical Applications

Several key markets and applications for nanofluids include:

- Heat Transfer Enhancements

- Power Apparatuss (nuclear and conventional); heat exchangers (chemical industry); heat pipes; thermal management of power electronics and other semiconductors; air conditioning; and refrigeration apparatuss

- Mass Transfer Enhancements

- Fermentations; protein/cell separation; drug delivery; and catalysts

- Rheology

- Lubricants (deep hole drilling)

- Magnetic Nanofluids (Ferrofluids)

- Rotary seals; cancer therapy (hyperthermia); NMR imaging; as well as magnetic cell sorting

Determining the correct nanofluid from a thermal perspective

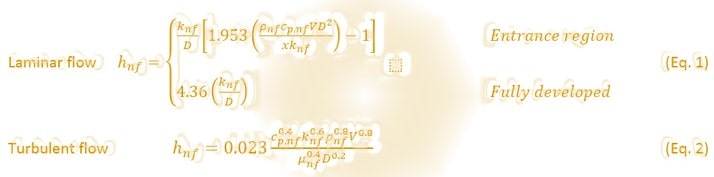

In the case of single-juncture heat transfer, it has been shown that the heat transfer coefficient and the amount of pressure loss can be projected by means of traditional correlations and models, as long as the measured temperature and loading dependent nanofluid properties are used.

Whereas hnf is the convective heat transfer coefficient of nanofluids; Knf, µnf, ρnf, cp,nf, are the thermal conductivity, viscosity, density and particular heat of nanofluid respectively; V is the fluid velocity, x is the space from the entrance of the tube and D is the conduit diameter.

Moreover, if accurate values of the thermo-physical properties for a specific nanofluid are available, the thermal conduct can be predicted. Apart from the specific heat and density, which can be identified by mixture guidelines, thermal conductivity and viscosity are the two most significant parameters for overall thermal evaluation of a specific nanofluid. It is expected that by dispersing nanoparticles with higher thermal conductivity in comparison to the base fluid overall thermal conductivity of the resultant nanofluid will be greater than that of the original base fluid.

This is advantageous because having a working fluid with higher thermal conductivity would result in a decrease of pumping power while achieving the same amount of heat removal. It can also be shown that if one can expansion the thermal conductivity of the working fluid by a factor of three (augmenting overall thermal conductivity is essentially what nanofluid does), the heat transfer in the same apparatus doubles. To give readers an idea, to expansion the heat transfer of conventional fluid by a factor of two, pumping power must frequently be expansion by a factor of eight. Consequently, using nanofluid with high value of thermal conductivity can provide large pumping power reduction in the apparatus.

Effective medium theory with Ck = 3 (for a dilute apparatus of spherical particles) can be used as a rule of thumb measures of the thermal conductivity estimation for the specific nanofluid. Obviously, measuring thermal conductivity and identifying Ck provides much more accurate value.

Wherever knf and kbf are the thermal conductivity of nanofluid and base fluid respectively; Ck is the constant that should be found by matching Eq. 3 to the experimental data; and ∅ is the volume segment of the particles.

Nevertheless, this is just half of the story, in addition to thermal conductivity, it was also evident that viscosity has a significant impact on the overall performance of a heat transfer fluid. Adding nanoparticles to the base fluid results in a higher viscosity of the resultant nanofluid. Clearly, pumping a fluid with expansion viscosity through a heat exchanger requires an expansion in pumping energy, thereby reducing the overall benefit of a fluid with higher thermal conductivity. Unfortunately, most of the equations for predicting viscosity of nanofluids under-predicts the experimental data by a huge margin. It was shown that for the first order estimation value of Cµ = 10 can be used in Equation 4 (please see below).

Whereas µnf and µbf are the viscosity of nanofluid and base fluid respectively and Cµ is the constant that should be found by matching Eq. 4 with the experimental data.

This shows that generally the enhancement in viscosity is higher than enhancement in thermal conductivity (Cµ = 10 compared to Ck = 3). Then the key question to be answered is: “Is there any advantage of employing nanofluids as a heat transfer fluid?”

Criteria for the overall effectiveness of nanofluids as heat transfer fluids have been proposed, which suggest that the expansion in the viscosity must be more than four times larger than the comparable expansion in thermal conductivity for a nanofluid to be not beneficial at all.

Therefore, the overall quick guideline for selecting a nanofluid for a specific application would be as follows:

- Use Equations 3 and 4 to estimate the thermal conductivity and viscosity of the nanofluid (measured values of the thermal conductivity and viscosity are obviously preferred).

- If the measured thermal conductivity and viscosity of the nanofluid of interest meets the requirements of Cµ<4 Ckmove to the next step. If not, the choice of nanofluid should be changed.

- Calculated/measured thermal conductivity and viscosity values should be implemented in Equations 1 or 2 (depending on flow) for the first order estimation of heat transfer coefficient enhancement.

Applications that Involve Boiling | Nanofluids

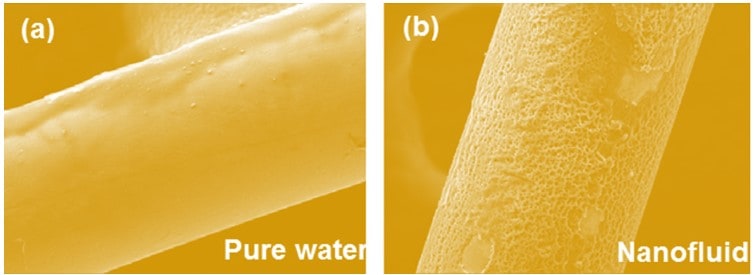

In applications that involve boiling, it was shown that the boiling of nanofluids result in a deposition of nanoparticles on the heated surface. Deposition of nanoparticles on the surface provides a porous, hydrophilic layer that alters the wettability of the surface. Due to the nano-scale porous nature of this layer, capillary wicking also plays an important role. Lateral flow of the liquid due to the capillary wicking supplies a fresh liquid to the dry region beneath the bubble and delays the irreversible growth of the hot spot, which results in critical heat flux (CHF). The exact mechanism behind the observed enhancement in the CHF value is still subject of debate in heat transfer community.

Scanning electron microscopy of the heated surface after boiling with (1a) DI-water and (1b) nanofluid

Cost Projections in the Field of Nanofluids

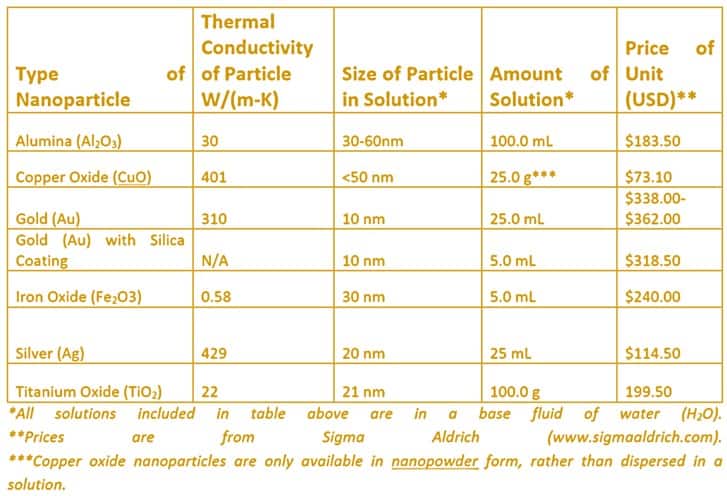

The overall cost of a nanofluid is determined by the price of the chosen base fluid and the price of the nanoparticles themselves. Prices are higher when the nanoparticles are more difficult to synthesize or the process for creating the stable colloidal suspension is more challenging. Table 1 presents an estimation of the price for some common nanoparticles with water as the base fluid. The thermal conductivity of the resultant nanofluid is a function of the nanoparticle’s thermal conductivity. Clearly, nanoparticles with higher value of thermal conductivity provide higher enhancement.

Regulatory Considerations

Many nanoscale materials are deemed merely as “chemical substances” under the U.S. Environmental Protection Agency (EPA) Toxic Substance Control Act (TSCA). TSCA requires manufacturers of new chemical substances to provide specific information to the Agency for review prior to manufacturing chemicals or introducing them into commerce. The EPA can take action to ensure that chemicals that may pose an unreasonable risk to human health or the environment are effectively controlled. The EPA’s bulletin, “Management of Nanoscale Materials under the Toxic Substances Control Act” outlines the regulatory framework for nanoscale materials. Most engineers implementing nanofluids for thermal management would be acquiring these materials from another manufacturer.

Core Industry Drivers in Nanofluids

Market drivers are forces that compel products and services to change in order to meet consumer or business demand. A useful construct for those drivers is a STEEPLE analysis, which considers seven broad factors of market drivers: Socio-Cultural, Technological, Economic, Environmental, Political, Legal and Ethical. This section deals with two to three key technological drivers for the most relevant heat transfer enhancement applications such as: power plants, power electronics and other semiconductors, and heat pipes.

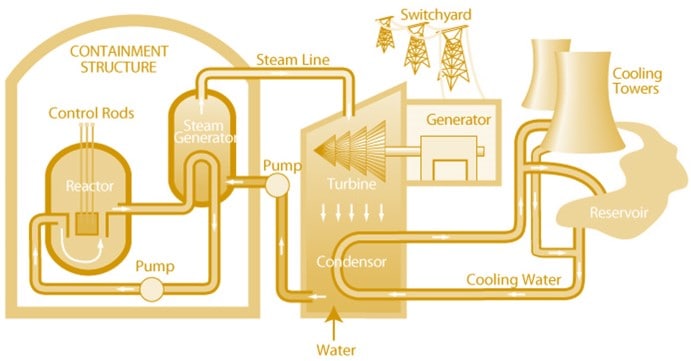

Power Apparatus’ (atomic and traditional)

Virtually all developed countries rely on a national power grid for their nations to grow and prosper. Nanofluids can play an important role in this space by improving the outcome and cost-efficiency of existing power plants. The use of nanofluids to cool a power plant can significantly reduce the resources consumed and the cost in electricity to run it. These cost savings and the greater efficiency that nanofluids provide can also eliminate the need for building additional power plants, which is a massive financial boost for a country, state, or municipality.

In power apparatus’, the key technological drivers to consider for the implementation of nanofluids include:

- Nuclear

– Improving the energy efficiency of a nuclear power plant by improving the functionality of existing power apparatus’.

– Cost and regulatory avoidance by not having to build additional infrastructure since the efficiency of existing infrastructure can be improved to the degree that more building is unnecessary.

– Safety of nuclear power plants by improving the cooling of nuclear rods (in a pressurized water reactor, by pushing the point at which a rod might overheat (CHF) to a higher value.

- Solar

– Improvement to heat transfer by increasing the heat transfer performance of the fluid in the solar collectors for hot water supply.

- Conventional

– Improvement in power plant efficiency through various methods including higher heat capacity of the heat transfer fluid.

– Reduction in the dimension of heat exchangers.

– Reducing vapor pressure to reduce plant risk.

– Improvement in the stability of heat transfer fluids with a goal of keeping the consistency of energy conversion stable.

Power electronics and Semiconductor Simulation Software (SoC)

With the advent of cloud computing, electric and hybrid vehicles, and the Internet of Things (IoT), electronics have become increasingly integrated into our lives. This integration of and the growth in applications drives an increasing need for more performance but at lower power and in smaller packages.

In power electronics and semiconductors, the core technology drivers are:

- Increasing speeds of semiconductors with simultaneous expansion in component densities.

• Increasing the performance of fluids for thermal management of electronics and migration from air to liquid cooling apparatuses.

• Improvement in energy efficiency of electronic apparatuses.

• Improving rack density for computing apparatuses through reducing apparatuses to sub-1U platforms.

• Improvement in power module life (MTBF).

• Thermal management of ever-increasing power densities.

Thermal Management & Heat Pipes

Heat pipes are increasingly used as a key component in thermal management solutions. Their ability to transfer large amounts of heat from one section of a apparatus to another makes them invaluable for keeping semiconductor junction temperatures within their proper range.

Core technology drivers for heat pipes and nanofluids are:

- Improving the heat transfer performance and temperature uniformity in heat pipes.

• Reduction of the thermal resistance (because of higher thermal conductivity of nanofluids).

• Increasing maximum allowable heat load of heat pipes by improving the wettability and providing larger surface area for thin-film evaporation in an evaporator (because of particle deposition because of evaporation).

Engineering Applications and Requirements | Nanofluids

Nanofluids are a broad category of engineered fluids. The composition and selection of a particular colloid is generally specific to a given application category. The following are some examples of applications that could use nanofluids and some general specifications as to why an engineer may want to choose them.

Computer servers for modern cloud computing

Cloud computing, with its large scale of servers, continues to grow and with this trend so too does the amount of energy data centers consume. Moving from air cooling to liquid cooling can create a more energy- and computationally efficient data center. When using water as the base fluid with nanoscale particles of zinc oxide, copper oxide or carbon nanotubes, for example, the colloid’s capability to conduct heat is improved 10-40% over water alone. The lower range of improvement is with a conventional heat exchanger, while the higher range requires a specially designed heat exchanger.

IGBT Modules and Power Electronics

Insulated-gate bipolar transistor (IGBT) modules, power brick and power semiconductors have ever-increasing heat dissipation requirements reaching 300 W/cm2 and higher. At those heat dissipation levels the constraints of cabinet dimension, apparatus density, noise levels and fan dimension make using liquid cooling with nanofluids a good thermal management strategy. As in other applications, an improvement of 10-40% may be possible by using nanofluids rather than water alone.

The implementations of liquid cooling can vary, but commonly involve heat pipes, vapor chambers or cold plates (either single or two-juncture) with a pump. Because of the unique thermal capabilities of nanofluids, all three implementations can be smaller, lighter, quieter and thinner than when deployed without nanofluids.

Developments in the field of Nanofluids

The idea of using liquid cooling for power electronics applications is no longer confined to theoretical observations or laboratory experiments. There is widespread use of heat pipes, for example, and personal computers frequently incorporate elaborate liquid cooling apparatuss. Nanofluids represent an enhancement to the technologies that are increasingly being used for cooling electronics.

Much of the ongoing research is focused on immersion cooling and boiling. In tests, boiling with nanofluids has been shown to improve the value of critical heat flux (CHF) by as much as 200% because of nanoparticle deposition on the surface of component. This has led to other research on, potentially, engineering the surface of high-powered electronic mechanisms with nanoparticles to improve heat dissipation without the need for an engineered liquid.

Researchers are also continually testing new materials to disperse in different fluids. For instance, aluminum oxide, iron oxide, zinc oxide, cerium oxide, and bismuth oxide are just some of the options that Nano-juncture Technologies Corporation offers to customers. In addition, there is work being done with carbon nanotubes that have shown promising results in heat transfer. New materials, such as graphene, are also being developed and tested to determine their potential for application in thermal management.

Other trends in the technology include the use of different materials such as copper, aluminum, and newly developed polymers for the loop of a liquid cooling apparatus or different wicking materials in the production of heat pipes and vapor chambers. In addition, improvements are being made in heat exchangers, pumps, and other components of liquid cooling apparatuses.

Trials and Tribulations, Nanofluids

While nanofluids have gained momentum and notoriety in the past two decades, there are still several challenges to their widespread commercialization. One of those challenges is that the concept of nanofluids is still relatively young. The term was only coined in the early 1990s and, while the number of studies has extended in recent years, there are no long-term assessments of how the addition of nanoparticles could affect a cooling apparatus over time. Nanoparticles could collect and cause degradation in a pump or heat exchanger, for example. There is a widespread belief in the stability and reliability of nanofluid solutions, but it has not been possible to document that over the course of a long period of time.

Also, there are questions that have been raised about the environmental impacts of disposing nanofluids from an apparatus, whether as vapor in the case of a nuclear power reactor or as liquid when replacing the fluid in a data center apparatus. While it is possible that nanoparticles in high quantities could be harmful, there are few studies that have focused on the environmental impacts or the impact on humans.

Conclusions | Approaching Market Disruptor

In conclusion, this report has summarized the potential applications of nanofluid in electronic cooling. It was shown that the thermal performance of the liquid cooled apparatus can be additional improved by dispersing nanoparticles in a base fluid. The guide for selection of the right nanofluid for specific application is provided. It was shown that the heat transfer coefficient enhancement in nanofluid can be predicted simply by implementing thermo-physical properties of the nanofluid of interest in the traditional models/correlation for single juncture convective heat transfer. It was also shown that the large enhancement in CHF value can be achieved by boiling nanofluid on a heated surface. Based on these basic principles employing nanofluid in different applications, their opportunities and challenges were discussed.