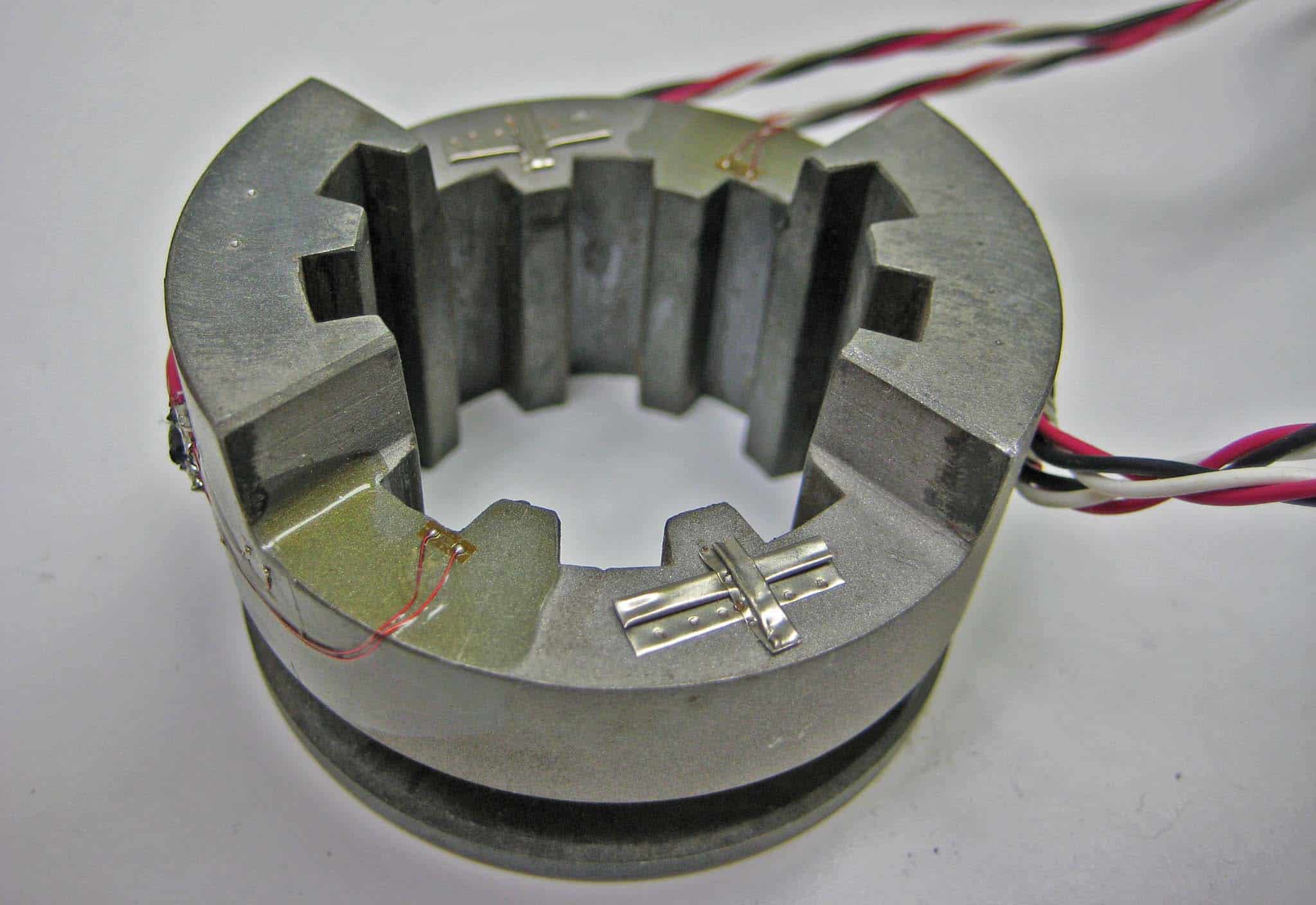

SimuTech Group performs strain gauge measurement both in its laboratory and on-site at customer facilities.

Strain gauge testing may be used to measure static strain due to relatively constant loads such as pressure or thermal expansion.

Strain gauges may also be used to measure dynamic strain due to transient events or vibration. Information from gauge measurements is useful for validation of finite element analysis (FEA) models, establishing more accurate operating loads and failure investigations.

SimuTech Group’s services also include selection of gauge size and type, specification of gauge locations and orientations, strain gauge installation, and recommendations for bonding methods.

Our engineering experts will help your team develop practical strategies for dealing with lead wire paths, connection terminals, clearances and gauge environmental protection, data acquisition and analysis.

Gauge measurements are applicable to a wide variety of structures including industrial equipment, turbomachinery, aircraft, piping, automotive components, and electronics.

Recent strain gauge measurement applications by SimuTech include automotive radiators, a helicopter airframe, a forging press, a bridge truss structure, and a high-pressure gas main.

Strain gauges are ideal for verifying stress and displacement simulation models. The strain gauge measurements are taken at specific locations and correlated with the simulation results.

Modeling assumptions such as boundary conditions, contacts, and loads may be updated to make the simulation better fit the observed behavior.

Once the model accurately reflects the measurements, more detailed information about the system can be inferred.

In addition, simulations of the modified system can be used to predict behavior with confidence.

SimuTech Group specializes in both strain gage measurement as well as simulation, allowing seamless support when conducting investigations.