Electronics reliability has become a critical factor for an increasing number of industries and applications. Manufacturers’ trends toward adding new features, accelerating time-to-market, improving first-pass yield, and decreasing warranty rate create a significant challenge for the design and development of modern electronics systems.

The Ansys Electronics solution suite reduces testing costs, maintains regulatory compliance, increases reliability, and cuts product development time in half, all while assisting you in developing world-class and cutting-edge goods.

Electronics reliability has become a critical factor for an increasing number of industries and applications. Manufacturers’ trends toward adding new features, accelerating time-to-market, improving first-pass yield, and decreasing warranty rate create a significant challenge for the design and development of modern electronics systems.

The Ansys Electronics solution suite reduces testing costs, maintains regulatory compliance, increases reliability, and cuts product development time in half, all while assisting you in developing world-class and cutting-edge goods.

What is Electronics Reliability?

Electronics reliability is a metric that assesses how well an electronic component or system performs over time in its intended usage environment. Electronics reliability is vital to product performance and the company’s image, whether you work in the automotive, aerospace, military, medical, or high-tech/consumer electronics industries.

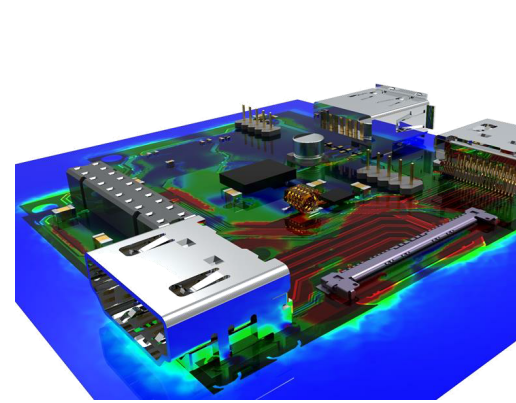

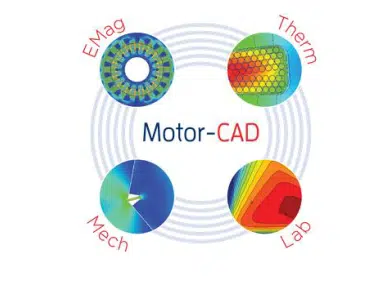

Ansys’ Electronics Reliability solution solves potential electrical, thermal, and mechanical issues with an automated product workflow that identifies at-risk components and failure modes, as well as providing full product lifetime predictions — all while being accessible by multiple teams and departments through Ansys’ intuitive interfaces including Ansys Electronics Desktop, Workbench, Mechanical, LS-DYNA, Sherlock, and Icepak integrations. This comprehensive Electro-Thermo-Mechanical Reliability workflow can improve product reliability and operational performance while addressing the challenges of modern electronics systems.

Why is Electronics Reliability Important?

- Increasing Number of New Features

- Lowering BOM Cost

- Maintaining Engineering Headcount

- Accelerating Time-to-Market

- Improving First-Pass Yield

- Decreasing Warranty Rate

- Electronics Reliability is Critical to All Industries and Technology Trends!

Ansys Electronics Reliability Engineering Challenges

It is becoming more difficult to ensure the reliability of electronic designs, and businesses cannot afford to be in an endless loop of test-fail-fix-repeat during the product development cycle. In addition to the challenges of reducing overall time and cost for product development, the following design requirements are often needed to meet the demands the modern world places on electronic systems:

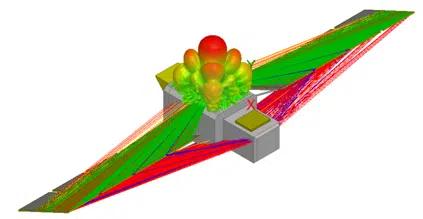

- Meet or exceed power and signal integrity goals

- Minimize EMI (Electromagnetic Interference)/EMC (Electromagnetic Compatibility) risk

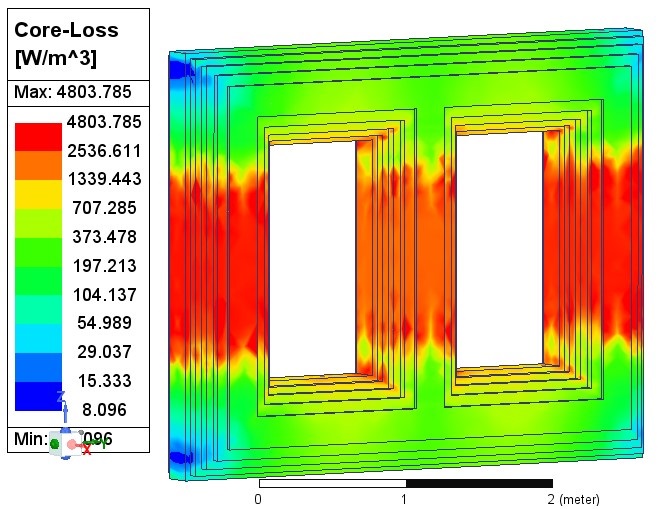

- Optimize cooling strategies for improved thermal performance

- Withstand severe shock, vibration, and drop events

- Robustness in the presence of design, material, and manufacturing variations

- Minimize system integration, assembly, and product transportation risks

Simulation Capabilities Required to Realize These Benefits

Learn how your products will behave by optimizing design via simulation rather than prototype building and testing, which is expensive and time-consuming.

Design Democratization: Organizations may use Ansys Electronics Reliability solutions to enable a wide variety of engineers to perform reliability assessments. These solutions allow for rapid iteration of design-reliability trade-offs and communication of results across the organization.

Workflow Automation: Engineers can build detailed simulation workflows with high levels of automation using Ansys Electronics Reliability software.

Robust Reliability Predictions: The cornerstone of the Ansys Electronics Reliability portfolio is reliability predictions based on physics of failure (PoF) concepts. Electronics manufacturers may use Ansys modeling software to figure out how long it takes for a product to fail and why it fails.

Electrical, Thermal, and Mechanical Analysis: Integrated workflows between Ansys Sherlock, Icepak, Mechanical, LS-DYNA, and more provide the simulation results necessary to optimize product designs and ensure reliability in the field.

Electronics Design Simulation

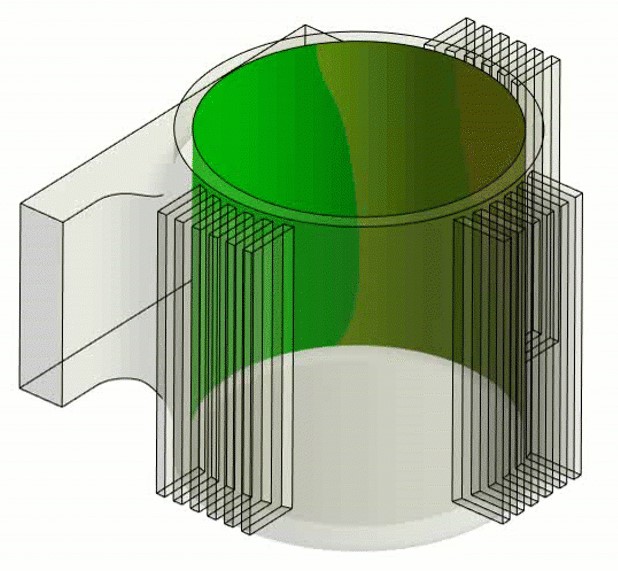

Solve the most important aspects of your product designs with Ansys simulation solutions. If you work with antenna, RF, microwave, PCB, package, IC design or even an electromechanical device, we provide you with the industry gold standard simulators. These solutions help you solve any electromagnetic, temperature, SI, PI, parasitic, cabling and vibration challenges in your designs. We build on this with complete product simulation, allowing you to achieve first pass success designing an airplane, car, cellphone, laptop, wireless charger, or any other system.

Learn how you can reduce your design-cycle and time-to-market by ensuring your electronics design is validated, cost-effective, operable, and certification ready. View this on-demand webinar: Address Electronics Reliability Challenges with Ansys Solutions