Ansys Forte

Ansys Forte is a computational fluid dynamics (CFD) software for modeling internal combustion engines and positive displacement compressors.

Ansys Forte is a computational fluid dynamics (CFD) software for modeling internal combustion engines and positive displacement compressors.

Accurately Model your Engine or Compressor with Advanced Chemistry and Meshing

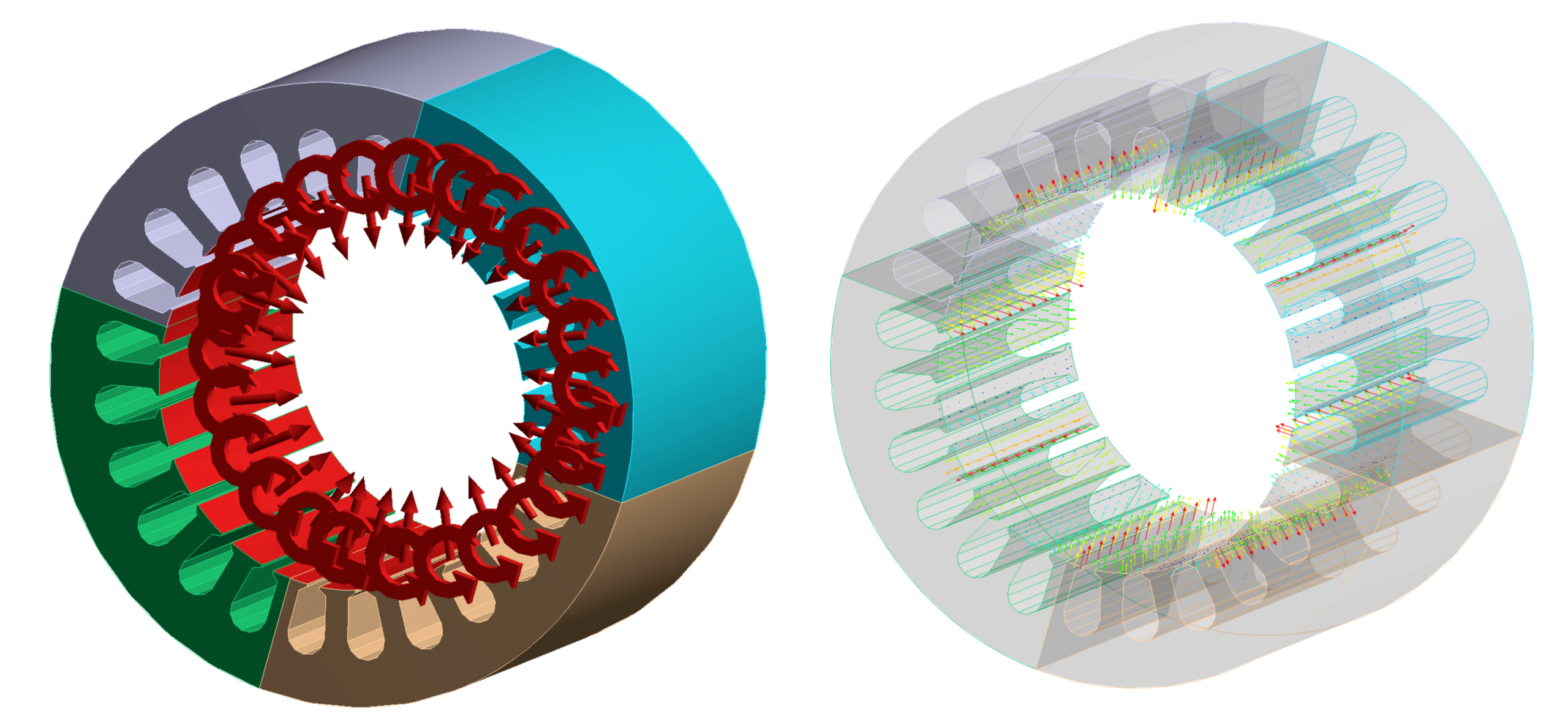

Forte incorporates the proven Ansys Chemkin-Pro solver technology for validated gas phase and surface chemistry. This positive displacement compressor and internal combustion engine design software can accurately predict performance and design improvements in real-time.

Streamlined workflows and automatic mesh generation reduce hands-on time. In addition, multicomponent fuel models expand scope of design applicability, and mitigate overall design and prototype costs.

Reduce time-to-market with the industry-leading engine modeling software. Utilize a fast chemistry solver to predict ignition, emissions, fuel effects and soot.

During the fuel vaporization process, the volatile components evaporate first, which dominate the location near the nozzle exit. Important insights for these multicomponent fuel models and associated processes, includes:

Ansys’ most powerful computational fluid dynamics tool, Fluent, includes well-validated physical modeling capabilities to deliver fast, accurate results across the widest range of CFD and multiphysics applications.

Ansys CFX is a high-performance computational fluid dynamics tool that delivers reliable and accurate solutions quickly for a wide range of applications, including leading capabilities for rotating machinery.

Ansys EnSight is the market leader for data visualization. Its post-processing tool includes models with more than hundreds of millions of cells, providing engineers with insights unavailable elsewhere.

Ansys Polyflow provides advanced fluid dynamics technology for companies in the polymer, glass, metals, and cement processing industries.

Ansys Chemkin-Pro is the gold standard for modeling and simulating complex gas phase and surface chemistry reactions for fast, accurate development of combustion systems.

Ansys TurboGrid complements rotating machinery simulation with a specialized, easy-to-use tool for the rapid 3D design of rotating machinery components.

Ansys BladeModeler complements rotating machinery simulation with a specialized, easy-to-use tool for the rapid 3D design of rotating machinery components.

Ansys Vista TF complements rotating machinery simulation by enabling engineers to quickly develop blade geometries that achieve desired performance objectives.

FENSAP-ICE is the premier in-flight icing simulation system. Its innovative, graphical environment provides intuitive file management and makes it easy to interact between simulation modules.

Mosaic Mesh, a Hexahedral Dominant Mesh Software accelerates the meshing process with a reduced face count, higher quality cells and efficient parallel scalability.

Fluent meshing provides automation to highly crafted meshing. Methods available cover the meshing spectrum of high-order linear elements to tetrahedral and polyhedral analysis.