Commercial CFD Solvers

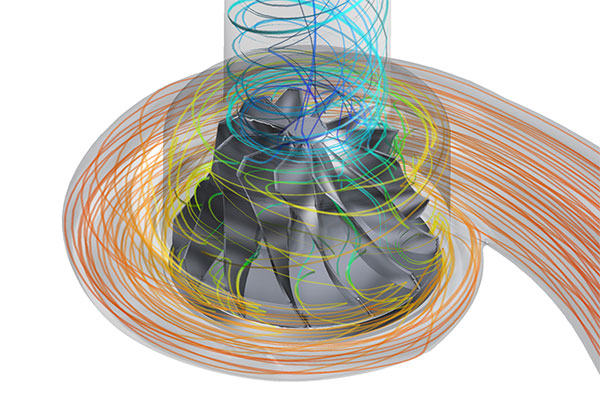

Turbomachinery Technologies at the Cutting Edge.

When it comes to turbomachinery applications, CFX is the gold standard CFD program due to its extreme robustness. Both the solver and the models have a modern, intuitive, and versatile user interface with extensive customization and automation capabilities via session files, scripting, and a powerful expression language. Pumps, fans, compressors, and turbines can all benefit from highly scalable high-performance computing.

- Streamlined Turbo Setup and Post

- Transient Blade Row Methods

- Rotor-stator Interaction Models

- Highly Scalable HPC

Purchase Ansys CFX

Ansys CFX Capabilities

Engineers can use Ansys CFX’s advanced physics simulation capabilities to address the most difficult problems in turbomachinery applications. This strong software has undergone rigorous testing and is known for its reliability and accuracy. You’ll have more time to spend refining your product thanks to streamlined turbo setups and blade design tool integration. CFX is the dependable tool you can use to save both time and money, whether it’s for blade design optimization or advanced material modeling.

Ansys CFX Key Features

Streamlined workflows with integrated blade design to aid in the optimization of your design.

From template to mesh to a robust result, streamline your workflow with our blade design tools or software partner offerings. For the best product changes, our turbo workflows provide design tools and optimization methods.

Improve the safety of rotating components through accurate and high-fidelity aeromechanical simulations.

Performing aeromechanical simulations early in the product design and development process helps improve the safety and the durability of rotating components. Transient blade row (TBR) methods are used to reduce geometries from full-wheel to a simple single passage. Aeromechanical simulation problems can be solved through time marching or harmonic balancing.

There are several turbulence models to choose from, helping you to find the right one for your needs. Ansys CFX includes the industry leading Generalized k-ω (GEKO) model which is a ground-breaking concept that uses tunable coefficients that can be adjusted to different flow regimes.

Validated models for bubble formation, phase shift, drag and non-drag forces are used to accurately model wall boiling and measure the critical heat flux.

Get the most accurate results with real gas and fluids properties.

The advanced material simulation capabilities of CFX assist in producing the most reliable performance. To effectively address changes in material properties, adaptive methods can be used to construct real gas and fluid property tables from the REFPROP database (near critical point, for example). The built-in IAPWS database can be used to pick liquid water and steam properties.

Exhaustive List of Ansys CFD Products

Fluent

Ansys’ most powerful computational fluid dynamics tool, Fluent, includes well-validated physical modeling capabilities to deliver fast, accurate results across the widest range of CFD and multiphysics applications.

Fluent Meshing

Fluent meshing provides automation to highly crafted meshing. Methods available cover the meshing spectrum of high-order linear elements to tetrahedral and polyhedral analysis.

EnSight

Ansys EnSight is the market leader for data visualization. Its post-processing tool includes models with more than hundreds of millions of cells, providing engineers with insights unavailable elsewhere.

Polyflow

Ansys Polyflow provides advanced fluid dynamics technology for companies in the polymer, glass, metals, and cement processing industries.

Chemkin-Pro

Ansys Chemkin-Pro is the gold standard for modeling and simulating complex gas phase and surface chemistry reactions for fast, accurate development of combustion systems.

TurboGrid

Ansys TurboGrid complements rotating machinery simulation with a specialized, easy-to-use tool for the rapid 3D design of rotating machinery components.

Forte

Ansys Forte accurately simulates IC engine combustion performance with nearly any fuel, helping engineers rapidly design cleaner burning, high-efficiency, fuel-flexible engines.

VistaTF

Ansys Vista TF complements rotating machinery simulation by enabling engineers to quickly develop blade geometries that achieve desired performance objectives.

BladeModeler

Ansys BladeModeler complements rotating machinery simulation with a specialized, easy-to-use tool for the rapid 3D design of rotating machinery components.

Mosaic Meshing

Mosaic Mesh, a Hexahedral Dominant Mesh Software accelerates the meshing process with a reduced face count, higher quality cells and efficient parallel scalability.

FENSAP-ICE

FENSAP-ICE is the premier in-flight icing simulation system. Its innovative, graphical environment provides intuitive file management and makes it easy to interact between simulation modules.

Ansys CFD Licenses

CFD Enterprise

To benefit from all the computational fluid dynamic solvers that Ansys offers, choose the CFD Enterprise toolkit. CFD Enterprise offers full versions of Ansys Fluent, AIM Pro, and CFX to help you optimize product performance with well-validated physical modeling capabilities that deliver quick, accurate results.

Engineers use Ansys CFX for the most accurate, robust, and rapid simulation for rotating machinery such as fans, pumps, compressors, and gas and hydraulic turbines. Companies in the glass, metals, polymer, and cement industries can choose Ansys Polyflow for advanced fluid dynamics technology.

CFD Premium

Today’s experienced engineers need well-validated CFD results to analyze products quickly and thoroughly. With full versions of Ansys Fluent, CFX, and SpaceClaim included, CFD Premium provides accurate, quick, and robust results.

Engineers can simulate IC engine combustion performance with Ansys Forte. Simulate with nearly any type of fuel to quickly design high-efficiency, clean-burning engines that are fuel flexible. To ensure speed and safety for in-flight icing certification, Ansys FENSAP-ICE provides accurate, rapid aircraft icing assessments, along with other comprehensive analysis in the aerospace industry.