Background

The Southerly Wastewater Treatment Plant (WWTP) is the largest of the three wastewater treatment facilities serving the Cleveland, Ohio metropolitan area. The plant cleans wastewater collected from homes and businesses and safely returns the water to local lakes and rivers. The wastewater removal is done in two stages: mechanical separation for removing large solids and biological processes for removing the remaining smaller solids.

IN 2011, civil engineering firm Burgess & Niple (B&N) entered into a contract with the Northeast Ohio Regional Sewer District for a proposed upgrade of the Southerly WWTP preliminary treatment facilities including an improved grit removal system.

Challenge

The primary function of the grit capturing tanks is to remove heavy inorganic sand and grit particles from wastewater. These large grit particles can cause problems for the downstream sewage pumps and settling tanks that are designed to process smaller grit particles and suspended wastewater solids.

Solution

B&N proposed to improve the particle removal capability by retrofitting the existing grit tanks with air injection nozzles near the bottom of the tank and a series of submerged flow baffles. These changes were intended to redirect slowly swirl the wastewater in the grit tank to increase the capture rate of larger sized grit particles. To evaluate the impact of the proposed grit tank modifications on removing the desired level of particulates under both nominal and peak flow conditions, B&N turned to SimuTech Group to conduct computational fluid dynamics (CFD) simulations.

The CFD analysis consisted of three phases:

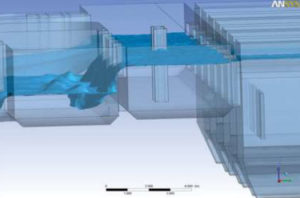

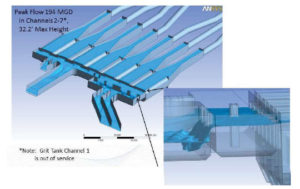

- Verify the water levels at normal and peak flow rates through the facilities’ seven grit channels matched B&N hydraulic models and actual water levels measured at the wastewater facility.

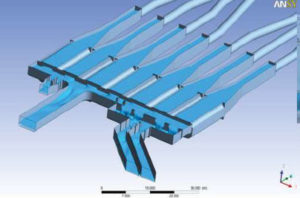

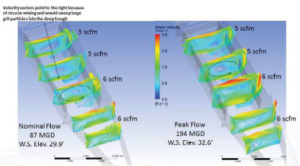

- Model wastewater flow through a single grit tank with the proposed air injection nozzles and flow baffles installed. The CFD model was used to determine the required air flow from the nozzles to get the desired rotational flow in the grit tank. The analyses show that the proposed longitudinal baffle near the wall opposite the air inject nozzles was impeding the rotational motion in the flow. The elimination of this baffle saved $70,000 in proposed costs.

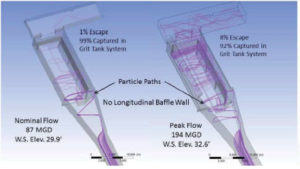

- Use the air injection conditions determined from the prior phase and release small and large grit particles into the wastewater flow upstream of the grit tank and track the path of these particles as they flowed through the grit tank system. The CFD model predicted particle removal rates of near 80% for the smaller particles increasing to more than 90% for the larger sized particulates, for both nominal and peak flow conditions. This removal rate met the design goal and compares favorably with the performance of the current proposed grit tank design.

![]()