Introduction

Electronics play a pivotal role in modern product development. Whether it’s high-tech consumer electronics, electrical automotive parts, electric motors, or air and spacecraft, electronic components and systems are indispensable. As products become more complex and feature-packed, the risk of failure increases, making dependable systems and advanced electronics reliability solutions essential.

By leveraging simulation software to verify reliability early in the design process, engineering teams can:

- Cut material costs

- Shorten development timelines

- Improve first-pass success rates

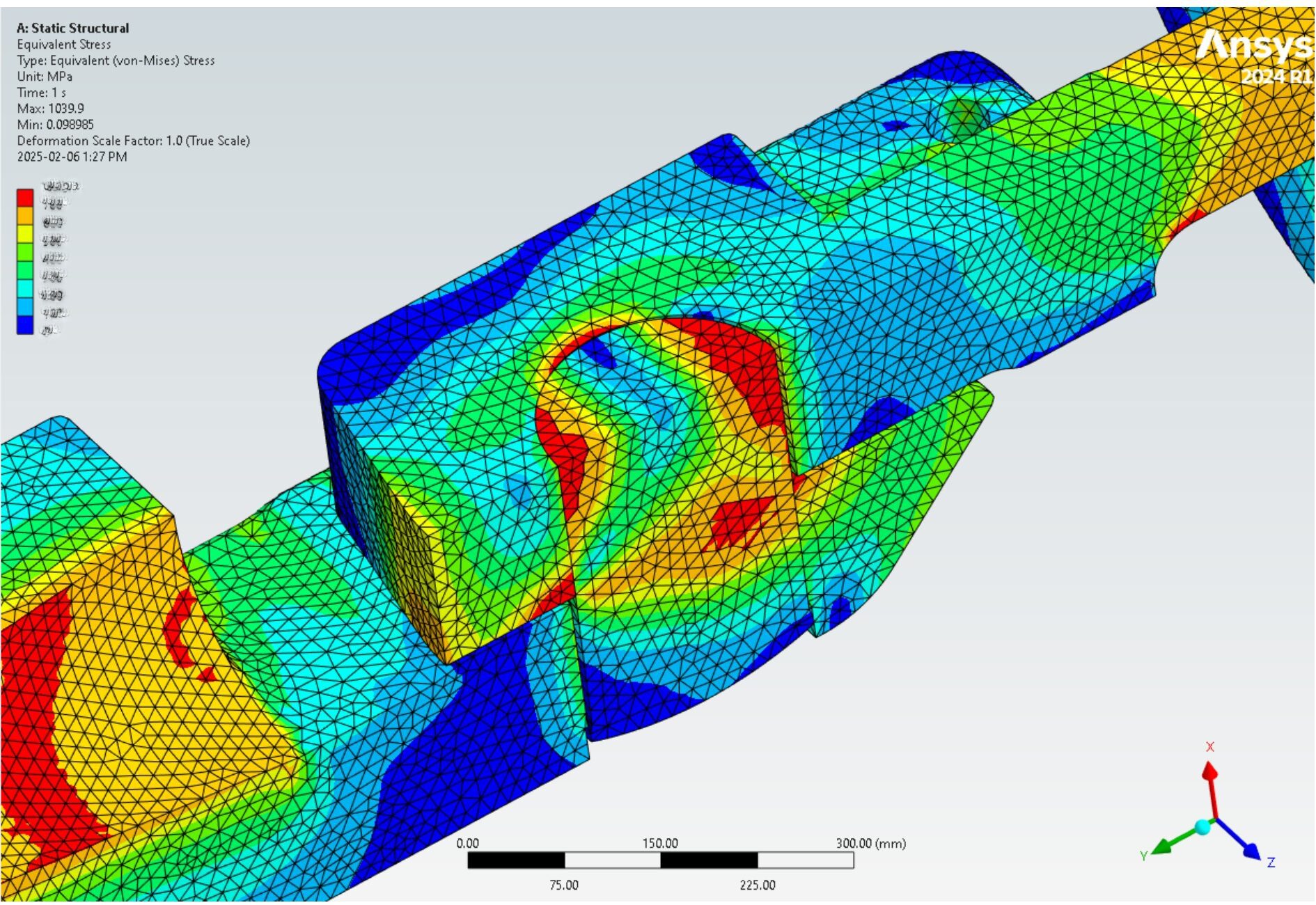

Achieving high reliability in electronics requires rigorous testing, quality control, and design practices to ensure devices and systems perform as expected throughout their lifespan. Advanced simulation tools like Ansys™ software enable engineering teams to uncover potential problems before they become critical.

What is Electronics Reliability?

Electronics reliability refers to the ability of electronic devices and systems to perform their intended functions without failure over a specified period under predefined conditions. This concept involves several key aspects:

- Durability: The capacity of electronic components to endure environmental conditions (for example: temperature, humidity, vibration) and operational stress without deterioration.

- Consistency: Ensuring the device maintains performance standards and quality specifications throughout its lifecycle.

- Fault Tolerance: Designing redundancies and fail-safes to allow systems to continue operating correctly despite component failures.

- Mean Time Between Failures (MTBF): A statistical measure estimating the average time between inherent failures during operation.

- Mean Time To Failure (MTTF): The average time expected before the first failure of a non-repairable device.

- Failure Rate: The frequency at which failures occur within a given time frame.

- Life Cycle Testing: Accelerated aging tests to predict long-term reliability.

Electronics reliability extends beyond individual components. It examines how electrical, thermal, and mechanical systems interact within the broader product design.

In fact, a recent Consumer Reports survey revealed that electric vehicles (EVs) experience 42% more problems than gas-powered vehicles, though this is an improvement from the 79% reported last year. Plug-in hybrids have 70% more issues compared to internal combustion models, down from 146% previously. These statistics highlight the ongoing challenges in electronics reliability within modern vehicles.

Advanced electronics reliability solutions ensure electronics systems in any type of product, not just EVs, work seamlessly to deliver long-lasting performance.

The Role of Simulation in Electronics Reliability

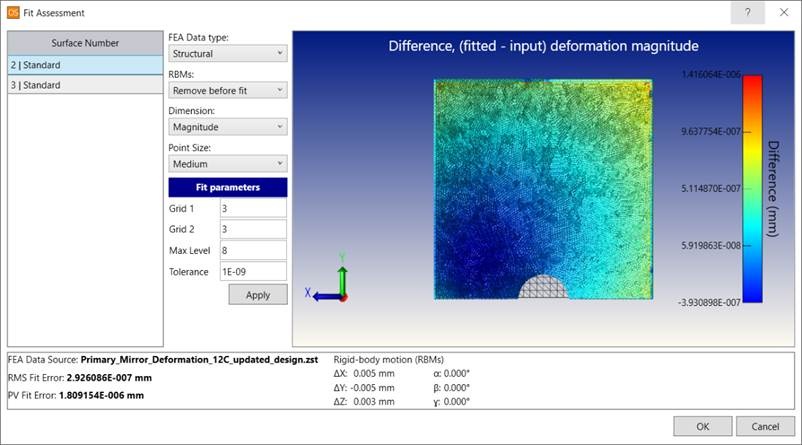

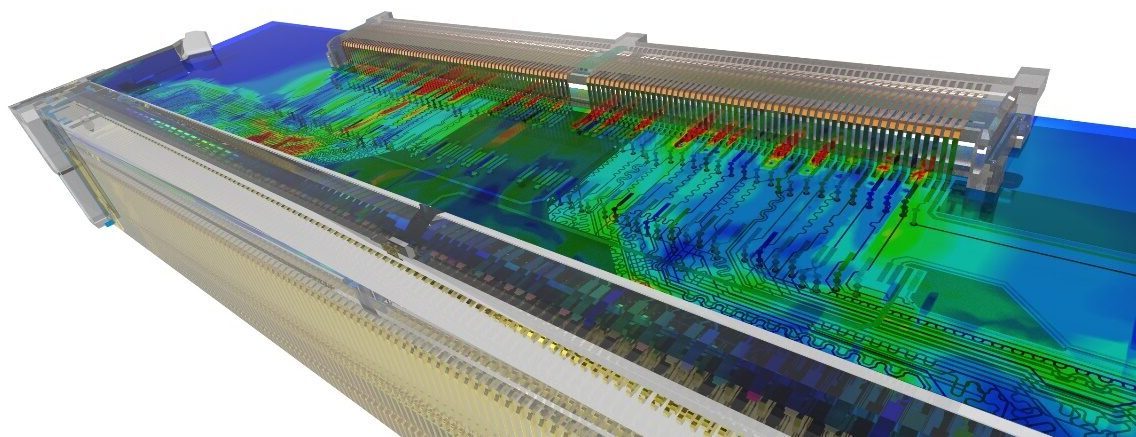

Simulation tools like Ansys Electronics Suite software provide a dedicated multiphysics solution for evaluating and improving electronics reliability. These tools help engineering teams:

- Identify at-risk components and failure modes

- Predict the full product lifecycle

- Make quick, informed design changes

By addressing electrical, thermal, and mechanical influences on printed circuit boards (PCBs) and other components, these electronics reliability solutions optimize overall system performance.

Electrical Reliability

At a larger scale, electrical reliability focuses on the consistent delivery of power within an electrical network, while electronics reliability refers to the dependable operation of electronic components and circuits within a device. Key aspects of electrical reliability include:

- Signal and Power Integrity: Engineers use simulations to evaluate multiple design options and optimize performance. Fully coupled systems integrate thermal and mechanical reliability with electrical simulations.

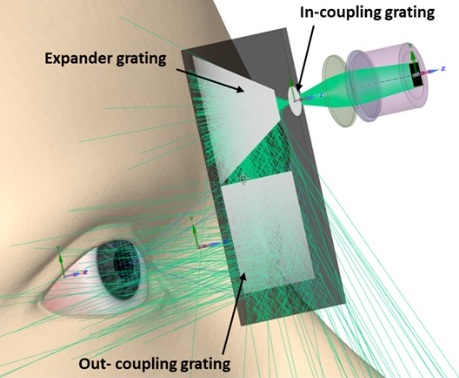

- Electromagnetic Interference (EMI): Simulation tools help mitigate EMI risk, which can cause systems to operate unintentionally and lead to unforeseen product failures.

By leveraging advanced simulation tools, engineers can ensure that electrical and electronic systems meet reliability standards, minimizing risks and enhancing performance across applications.

Conclusion

As electronics become more sophisticated, ensuring their reliability is paramount. Tools like Ansys simulation software enable teams to design products that stand the test of time, reducing costs, improving efficiency, and minimizing the risk of failure. By addressing the interplay of electrical, thermal, and mechanical factors, engineers can create systems that consistently perform as intended throughout their lifecycle.

Investing in simulation software is not just a means of preventing failure; it’s a strategy for delivering high-value, dependable products that meet the demands of an increasingly complex technological landscape.

Reach Your Electronics Reliability Goals Through Simulation

Ready to enhance your systems? SimuTech Group’s electronics reliability solutions can help you quickly and cost-effectively optimize designs for lasting performance. Contact us to connect with a simulation expert today!