Background

Headquartered in Millersburg, PA, Advanced Scientifics Inc. (ASI) (www.asius.com) is a leading global provider of advanced single-use systems for the Healthcare and Life Sciences Industries. The company’s Quality Management System and award-winning ERP system gave ASI the ability to provide an unparalleled level of customization rapidly and error free.

ASI’s Life Sciences division provides fully customized systems that allow Bio-Pharmaceutical manufacturers the flexibility to maximize efficiencies, minimize costs and alleviate risks in the production of Bio-Pharm therapies. Closely allied with industry supplies, the company is dedicated to providing the flexibility to integrate single-use systems for the Bio-Pharmaceutical Manufacturers’ unique processes.

Challenge

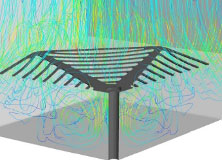

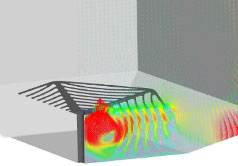

ASI’s imPULSE Single-Use Mixing System allows manufacturers to mix their powder/liquid or liquid/liquid solutions in an environment that eliminates cross contamination, requires less validation, and efficiently provides shorter cycle times and quicker start-up.

The imPULSE platform consists of a range of sizes starting at 30 L to 5,000 L for commercial mixing. The company needed a way to predict that the mixing would remain consistent across the size range.

Solution

In keeping with ASI’s constant diligence toward quality and service that has allowed the company to provide fully customized systems in the industry’s shortest lead-time with the highest level of quality. ASI turned to SimuTech Group’s team of CFD consulting engineers to predict the mixing across all sizes. Using Ansys Fluent CFD software, SimuTech Group’s engineers were able to confirm the mixer scalability using 250 L, 1,500 L, and 5,000 L sizes as baselines for small, medium, and large mixing. The CFD analyses provided a timely and cost-effective solution. The alternative would have been for ASI to build and test three physical prototypes which would have been more expensive and taken more time.