Mesh Refinement in Ansys Fluent

A CFD result is only as truthful as its mesh. If the grid misses steep gradients near walls, rotating components, or reacting zones, the solver can converge on numbers that look stable yet remain physically off the mark. Mesh refinement in Ansys Fluent gives you the control to place cells where physics demand them, trim cells where they add little value, and reach mesh-independent answers within your schedule and hardware limits.

This guide collects a few of the most effective Fluent tools and habits for refining the mesh with intent, not guesswork.

The Three Pillars of a Reliable Mesh

Enhance mesh refinement in Ansys Fluent: target critical gradients, protect solver stability with good quality metrics, and manage cell economy so every refinement measurably improves the solution.

Resolution Where it Counts

Refine near large gradients: boundary layers, shear layers, wakes, impingement zones, free surfaces, mixing regions, flame fronts, shocks, and narrow gaps.

Quality that Doesn’t Degrade the Solver

Watch skewness, aspect ratio, orthogonal quality, and smoothness between neighboring cells. Aerodynamic and turbomachinery cases benefit from low skewness and gradual size transitions.

Cell Economy

Add cells only where the solution improves. Use solution-based adaptation, local controls, and modern meshing technologies to avoid uniform over-refinement.

A Practical Workflow for Mesh Refinement in Ansys Fluent

Step 1. Start clean

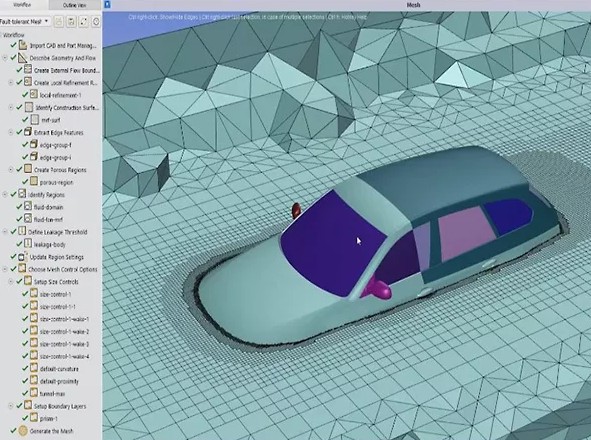

Import CAD in the Fluent single-window workflow. Use the watertight geometry tasks to fix gaps, slivers, and intersections. Poor geometry leads to poor mesh quality cells and long solve times.

Step 2. Build a baseline mesh

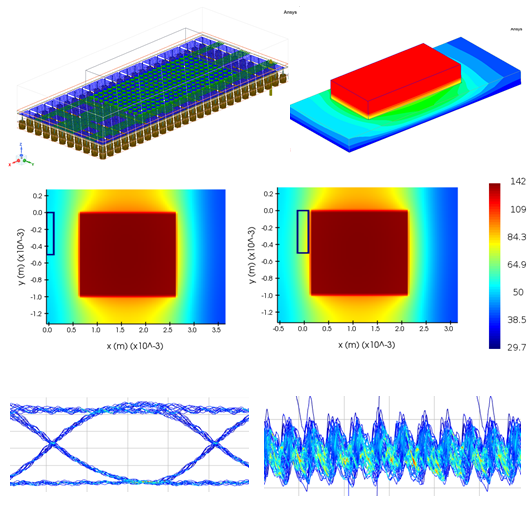

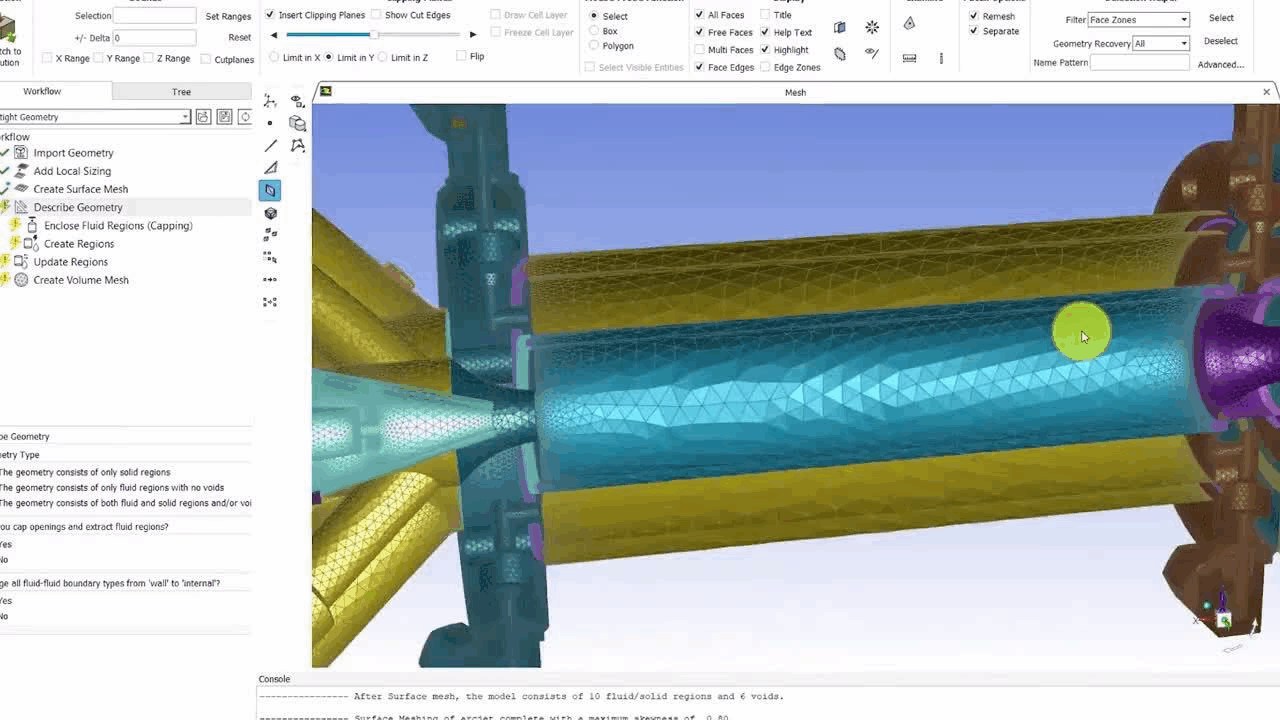

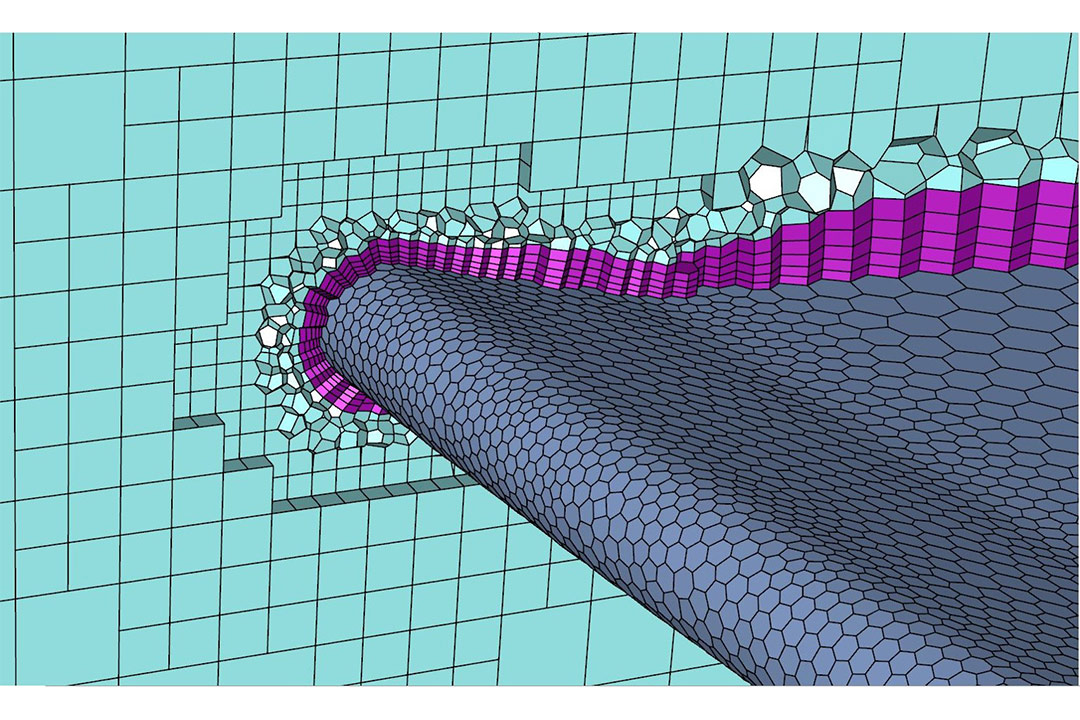

Create a coarse but well-structured grid. Use Ansys Mosaic poly-hexcore meshing for complex parts with inflation layers along walls for capturing near-wall gradients. Solve until the residuals level off and monitor points stabilize.

Step 3. Inspect what the flow wants

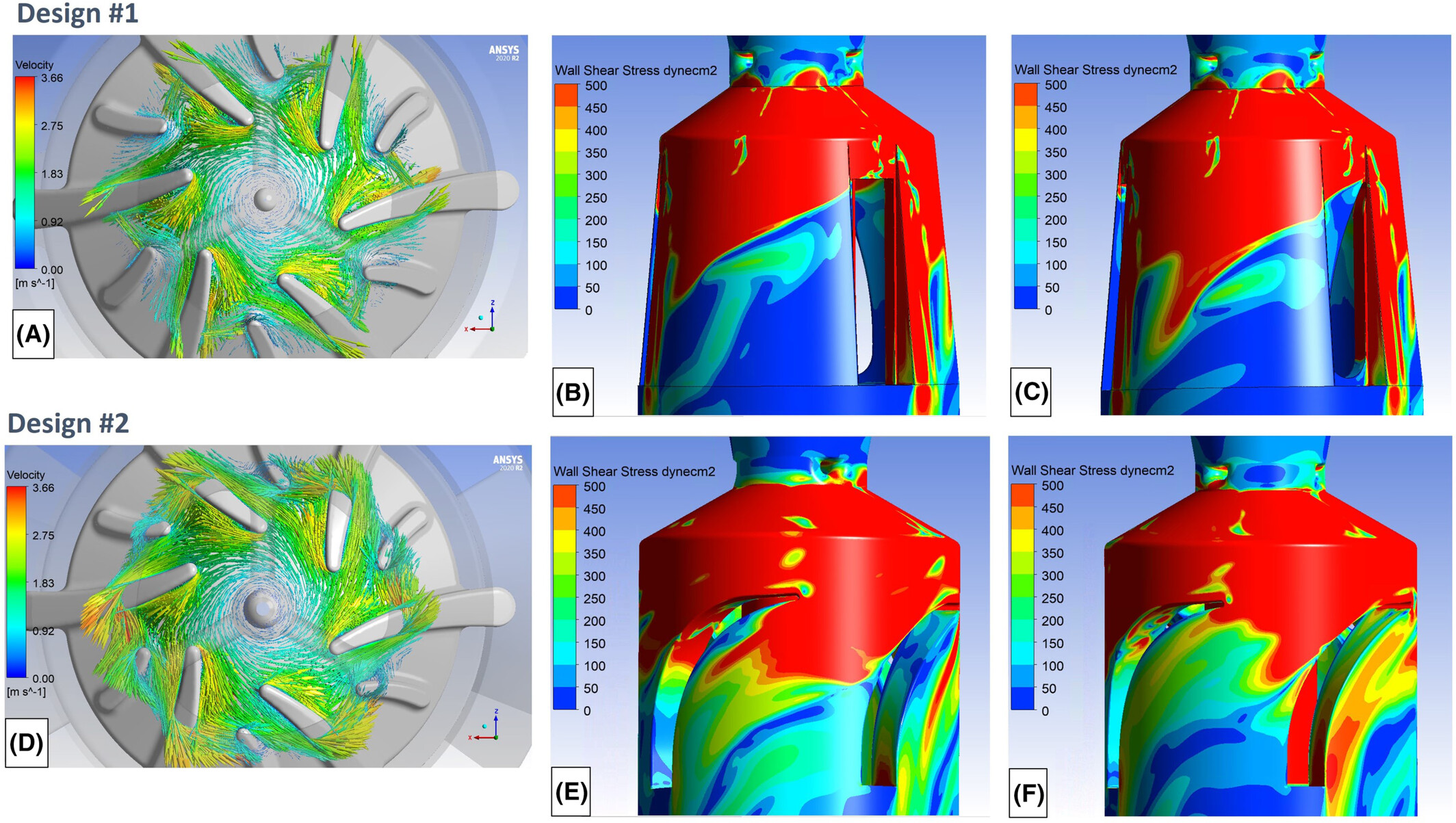

Plot contours of velocity, pressure, temperature, turbulence quantities, species, vorticity, and Q-criterion. Check y⁺ values on surfaces, used for assessing near-wall mesh resolution for turbulent flows, and wall shear stress levels. Identify under-resolved zones.

Step 4. Apply targeted local controls

Add bodies of influence, feature sizing, and curvature controls. Expand or refine inflation layers to meet y⁺ targets and maintain a healthy growth rate.

Step 5. Turn on solution-based adaptive mesh refinement (AMR)

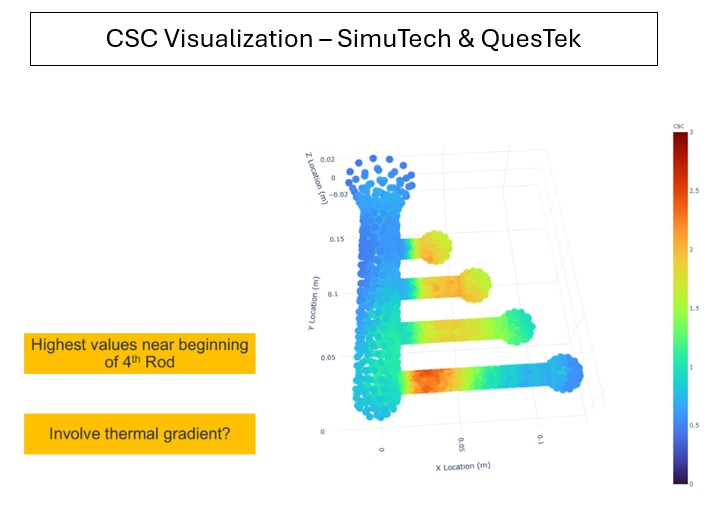

Use Ansys Fluent mesh adaption functions to refine cells where flow field gradients or error indicators are high. Typical choices:

- Gradient of velocity magnitude, pressure, or temperature

- Turbulent kinetic energy or vorticity

- Volume fraction gradient or interface curvature (multiphase)

- Species mass fraction or heat release rate (combustion)

- Q-criterion, which is used to identify swirling flow regions, for coherent structures

Limit the maximum cell count increase per adaptation cycle to maintain stability. Re-run for a few additional physical time scales or iterations, then adapt again if needed.

Step 6. Re-assess and iterate

Compare key outputs before and after refinement: integrated forces, pressure drop, heat transfer, wall shear, mixing index, mass flow splits. If changes fall below your acceptance threshold, you are approaching mesh independence.

Step 7. Document a mesh independence study

Generate two or three meshes that differ mainly in the refined regions. Show convergence of critical outputs with increasing resolution. Capture cell metrics and y⁺ statistics. This record supports design reviews and certification packages.

Using AMR Effectively for Mesh Refinement in Ansys Fluent

- Choose indicators tied to your objective. For pressure drop, adapt on the pressure gradient. For drag and separation, adapt to vorticity or Q-criterion. For hot spots, adapt to temperature gradient or heat flux.

- Control refinement depth and frequency. Too many levels of refinement at once can destabilize the solve. Refine incrementally, then advance the solution to let new cells “settle” into the solution.

- Balance refinement and time step. In transient cases, ensure the Courant number, a non-dimensional number used to set an appropriate time-step, stays in a healthy range after refinement.

- Coarsen where physics are smooth. Some workflows allow coarsening to keep the cell economy in check as flow features convect out of the domain.

Near-wall Resolution and y⁺ Management

- Set a target y⁺ early and compute the first-layer thickness from expected wall shear. Fluent can help estimate this with boundary layer tools.

- Keep layer growth rates modest, often between 1.15 and 1.25, to avoid abrupt transitions.

- Avoid truncating layers at sharp corners. Blend layers through difficult regions or locally modify the geometry to improve meshing behavior.

- Follow the wall function guidance for your chosen turbulence model.

Highly Efficient Performance Tips

Parallel meshing and solving: Use the parallel meshing capability to reduce pre-processing time for large models.

Hybrid meshing: Poly-hexcore meshes often yield faster convergence with fewer cells and similar accuracy when compared with all tetrahedral meshes.

Feature suppression for early passes: Suppress tiny fillets or holes that do not influence the physics of interest, then reintroduce them for final verification if needed.

Monitors over residuals: Monitor physically meaningful quantities like lift, drag, pressures at different tap locations, or average outlet temperature to judge convergence. Assessing residuals alone can be misleading.

Ansys Fluent Mesh Refinement Use Cases

- Automotive aerodynamics: Refinement around A-pillars, mirrors, underbody, and wake for accurate drag and lift; AMR on vorticity/Q-criterion during transient yaw studies.

- Aerospace nacelle cooling: Layered refinement in boundary layers, tight gaps, and impingement zones; gradient-based AMR on temperature for hot spot prediction.

- Additive manufacturing gas flow: Adaptive refinement on jet shear layers and recirculation to predict spatter particle transport and shield gas effectiveness.

Where SimuTech Group Fits In

If your team wants to standardize a repeatable Fluent meshing playbook or scale AMR across programs, SimuTech Group can help you:

- Establish y⁺ targets and inflation layer strategies per application

- Build BOI and adaptation templates tied to key performance indicators

- Set up parallel meshing and Mosaic meshing workflows for large assemblies

- Train analysts and designers to reach mesh independence with fewer trials

The result is a repeatable meshing workflow that delivers faster solves, consistent accuracy, and documentation stakeholders trust.

Refine with Intent: Fluent Meshes You Can Trust

A great CFD result starts with a great mesh. Targeted Ansys Fluent mesh refinement puts cells where physics demand them — near walls, wakes, gaps, and hot spots — while adaptive methods and y⁺ discipline keep accuracy high without bloating cell count or runtime. Documented mesh-independence gives you results stakeholders can rely on.

If you’re ready to standardize Ansys Fluent meshing, SimuTech Group can help you build a fast, repeatable playbook. Contact us today to turn mesh refinement into a confident habit across your programs.