Overview

Design Department Inc. is a product design consulting firm that collaborates with medium and large corporations to develop new products. Specializing in the early stages of the product development cycle, they focus on concept development and engineering, ensuring their designs are both innovative and practical.

Unlike other firms that may produce imaginative but unrealistic designs, Design Department delivers grounded concepts with a high likelihood of moving into mass production. As Patrick Tetzlaff, General Manager, humorously puts it, “There are design firms that will give you a beautiful rendering of Bigfoot riding a unicorn, but you’ll never encounter that in the real world.”

At-A-Glance

Technology Used

Ansys LS-DYNA

Challenge

Inaccurate simulation tools led to inefficiencies, prolonged design cycles, and uncertainty in product durability.

Outcomes

- Reduced mold iterations from 12 to 2-3

- Shortened timelines with 1-3 simulations daily

- Improved confidence in complex tooling

- Enhanced expertise with SimuTech training

- Strengthened product durability and reliability

The Problem

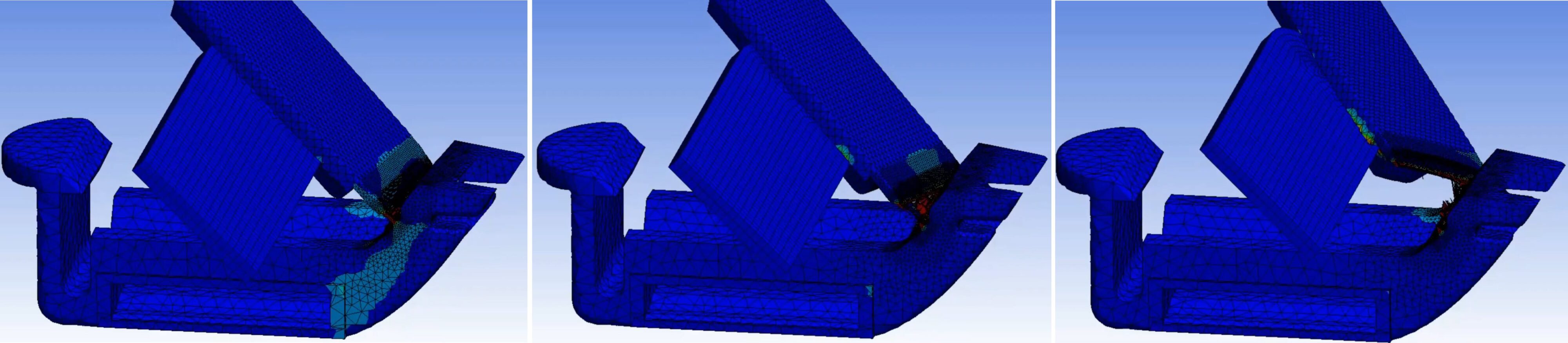

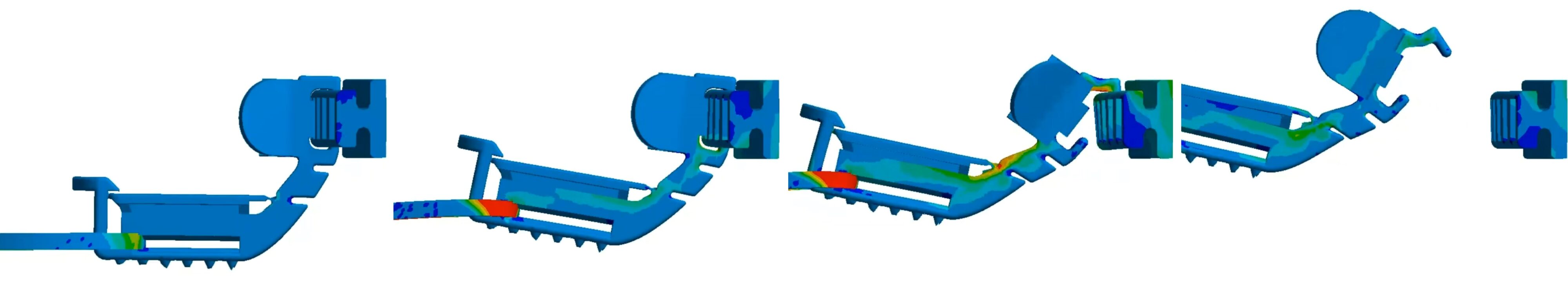

Design Department Inc. faced significant challenges in simulating the behavior of plastic components subjected to extreme conditions. Their existing tools struggled to accurately model parts approaching failure. This limitation led to inefficiencies in product development, including increased design cycles and uncertainty about whether products could withstand real-world stresses. As Tetzlaff noted, “We found ourselves wasting a lot of time with tools that weren’t appropriate for the job. There was uncertainty in whether the part would withstand the loads before breaking, leading to wasted hours and inefficient product cycles.”

The Solution

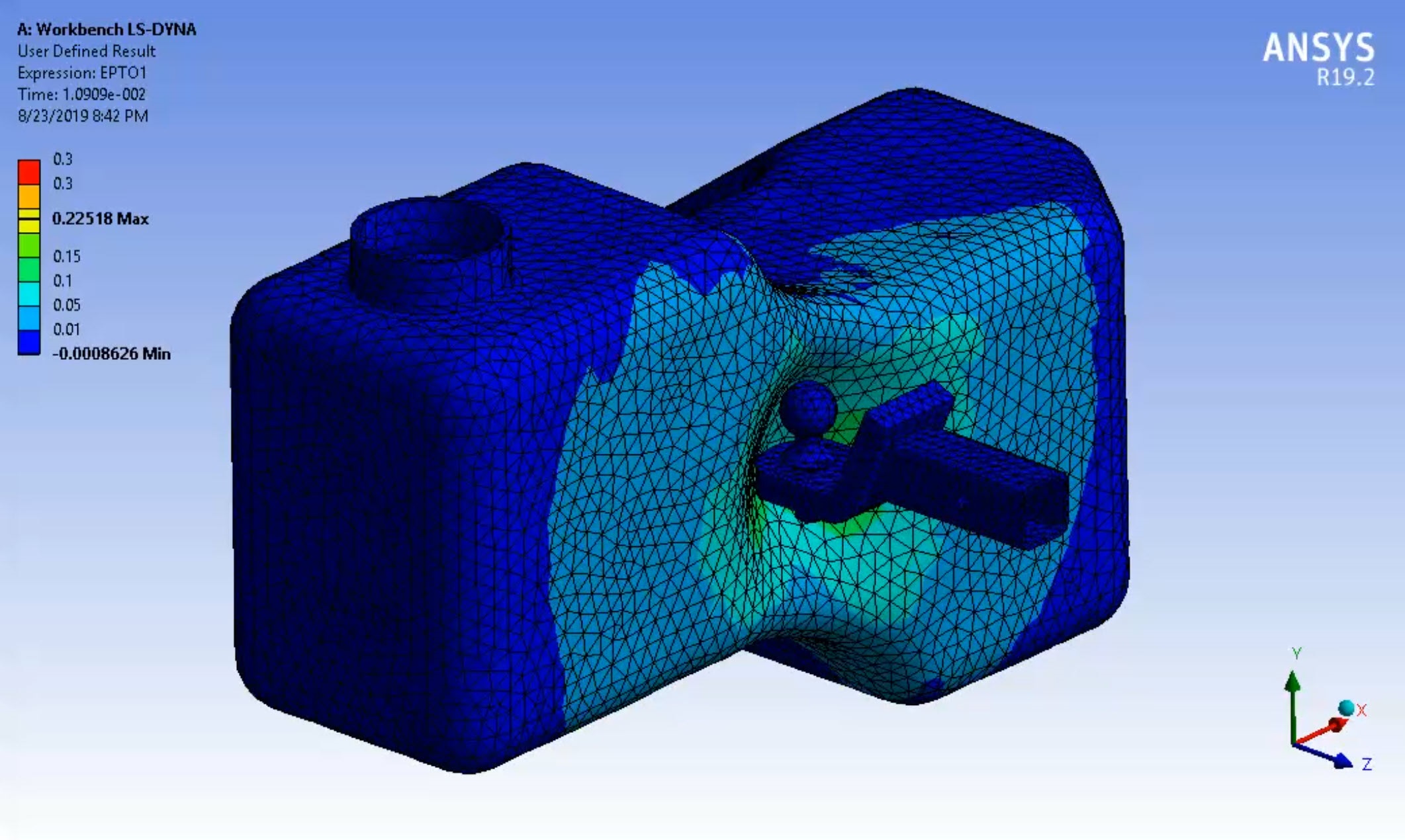

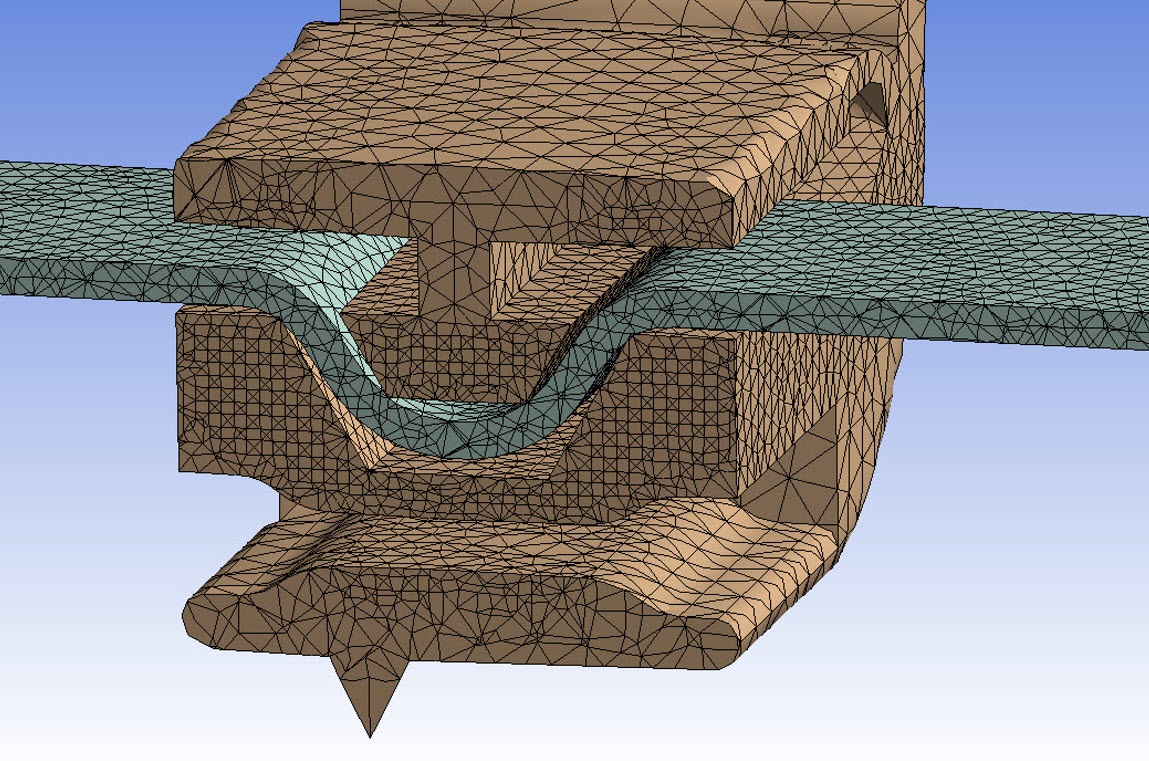

To address these issues, Design Department Inc. turned to SimuTech Group for Ansys simulation software, specifically LS-DYNA, which is renowned for its ability to handle large deformations and simulate nonlinearities in materials. The team was impressed by Ansys’ capability to model realistic behaviors, such as the way plastic parts stretch and yield when pushed to their limits. Design Department immediately put Ansys to the test, sending one of their toughest design problems to the SimuTech team. When the software demonstrated its ability to solve the issue, the firm adopted the software for their most complex projects.

The Benefits

Since integrating Ansys simulation software, Design Department has seen dramatic improvements in their design process. By using LS-DYNA, they reduced the number of physical mold iterations required for projects from a dozen to just two or three, saving both time and cost. The ability to simulate real-world conditions accurately has also increased the firm’s confidence in releasing complex, expensive tooling for production, ensuring fewer surprises during the manufacturing process.

We can now run through 1-3 simulations a day, cutting weeks off the project timeline. This is far more effective than getting numerous molds, which allows us to validate designs faster and with more confidence.

Patrick Tetzlaff

General Manager, Design Department Inc.

Collaborating with SimuTech Group

One of the key factors that amplified the benefits of adopting Ansys software was the support and training provided by SimuTech Group. SimuTech’s three-tiered support system made a significant difference in ensuring that Design Department Inc. could fully leverage the power of Ansys software. The team at Design Department had access to the SimuTech Skills Center, an online library filled with extensive training resources that helped their engineers quickly get up to speed with the software. In addition to this self-paced learning, they also participated in live training sessions where instructors guided them through real-world problems and provided hands-on exercises.

Tetzlaff emphasized the value of this blend of training: “The feedback from my team was very positive. They appreciated that it wasn’t just sitting and listening to a lecture, but involved real exercises where they could apply what they learned immediately. It’s a fantastic mix that really helped our engineers develop a strong understanding of the software.”

In addition to training, Design Department Inc. benefited from SimuTech’s technical support, which provided quick and effective responses whenever the team faced roadblocks. This ongoing assistance helped prevent delays and ensured that they could tackle complex simulations with confidence. The collaborative partnership with SimuTech Group empowered Design Department Inc. to maximize the efficiency of their product development cycles and make the most out of their Ansys software investment.

In Summary

Ansys simulation software combined with SimuTech Group’s comprehensive training and support has not only streamlined Design Department’s development processes but also significantly enhanced their ability to design robust, failure-resistant products. This powerful combination of cutting-edge tools and expert guidance has given Design Department Inc. a critical competitive edge in their industry.

Ready to Turn Your Innovative Concepts into Reliable Products?

At SimuTech Group, we empower design teams to bring practical, production-ready solutions to life. With advanced engineering simulation tools like Ansys LS-DYNA and expert engineering support, we help predict real-world behavior, streamline design cycles, and reduce costly iterations to give your projects the confidence and efficiency needed to succeed.