Aerospace Optical Design Considerations

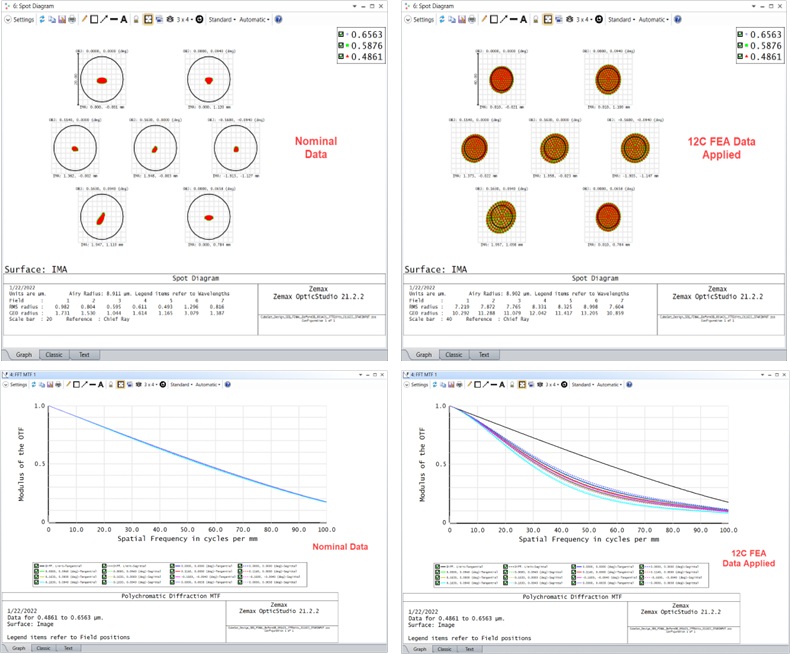

In aerospace optical system design, thermal deformation, coating-induced surface distortion, and misalignment from tolerance stack-up can significantly impair system performance. Identifying these effects late in the process, during prototyping or environmental testing, often leads to costly redesigns. Structural-thermal-optical-performance (STOP) and tolerance analyses allow engineering teams to quantify these risks early in the design cycle, supporting data-driven decisions around manufacturing methods and alignment strategies.

STOP Analysis and Predictive Performance Modeling in Aerospace Optical Components

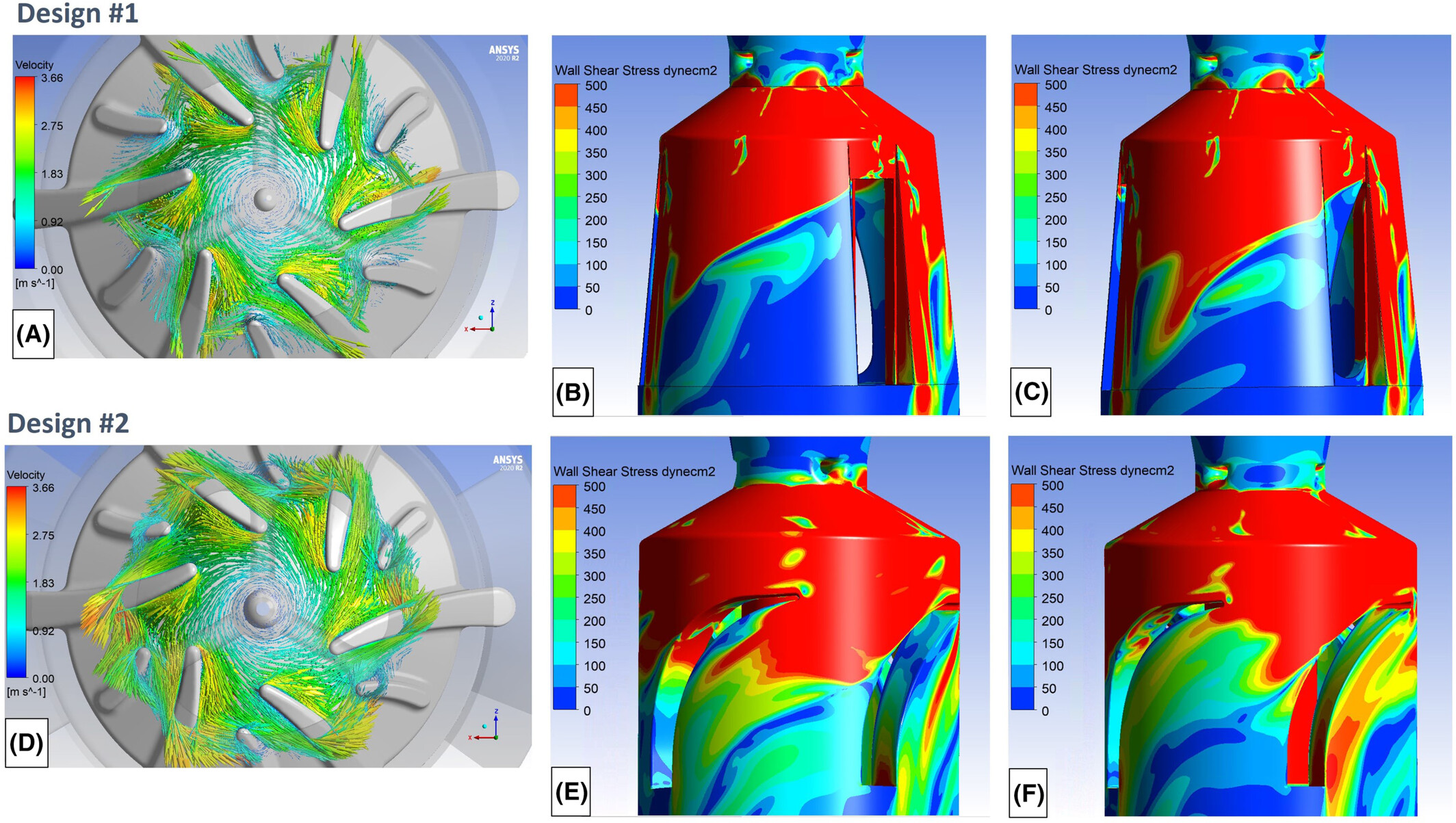

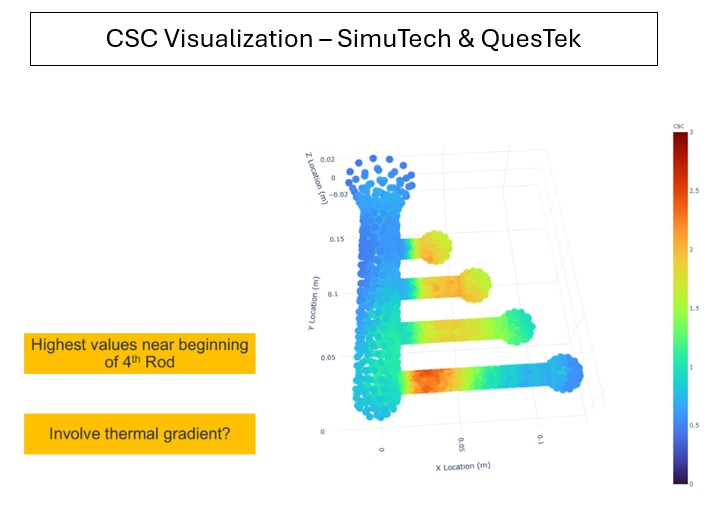

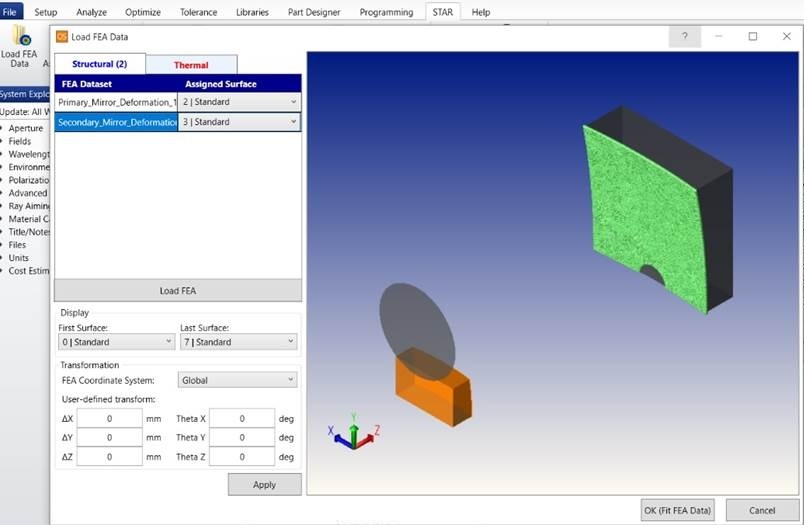

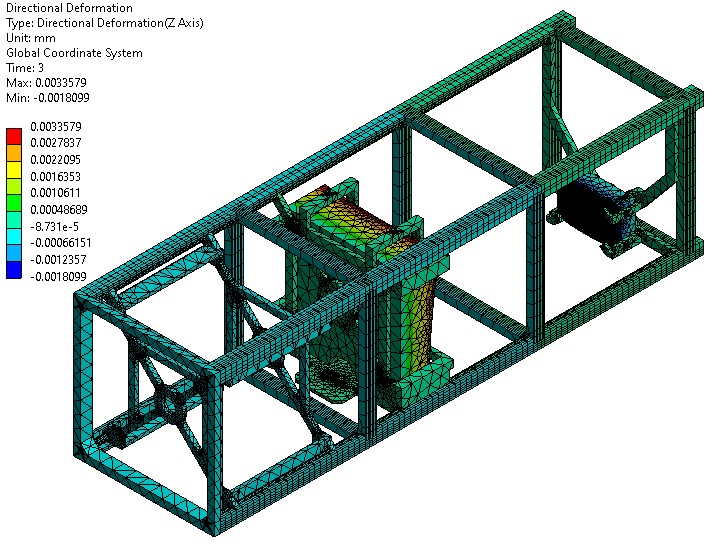

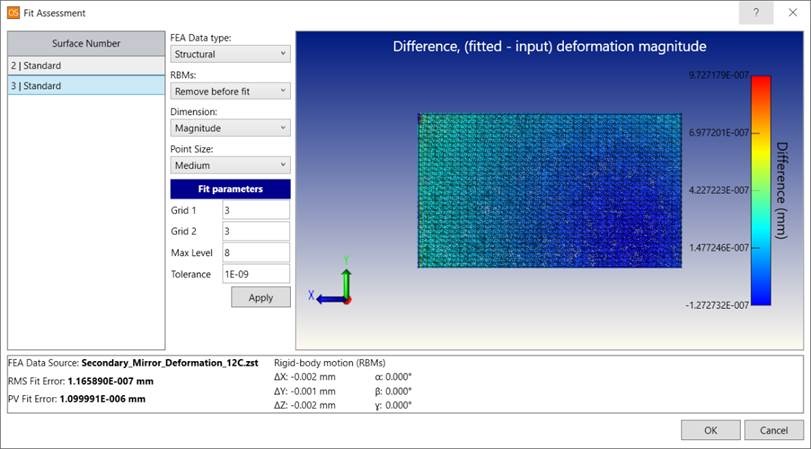

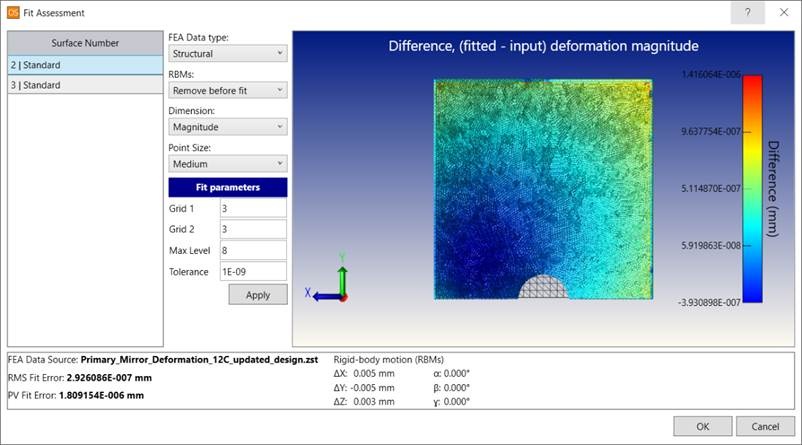

STOP analysis integrates structural, thermal, and optical simulations to estimate thermally induced degradation of optical performance. It is used at multiple stages of the design process, from conceptual sensitivity studies to final performance validation. Outputs include predicted mirror surface distortion, rigid-body motions, refractive index changes, system wavefront error, and pointing shifts—all of which can be mapped directly to optical performance metrics.

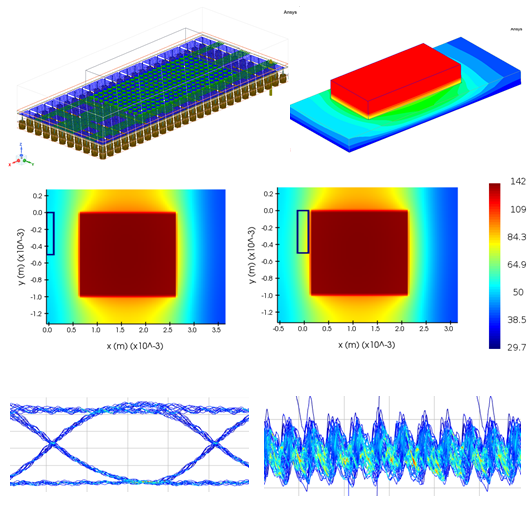

The process begins with thermal models providing temperature distributions under worst-case operating conditions common for aerospace optical components. These temperatures are input to structural models to compute resulting displacements, index changes, and stresses in optical elements. These deformations are then incorporated into optical performance simulations using ray tracing or wavefront analysis tools.

The fidelity of the STOP model progresses through the design phases—from simplified plate models in conceptual design to detailed representations of core and mirror geometries in final verification stages. This phased approach ensures increasing accuracy without delaying early development.

Tolerance Stack-Up and Alignment Error Propagation

There are no second chances in aerospace optical components. Tolerance analysis evaluates the cumulative effect of manufacturing and assembly deviations. Monte Carlo-based simulations model how combinations of small variations, such as lens decenter or optic tilt, affect performance metrics like RMS wavefront error or image blur. This process allows design teams to identify critical tolerances that require tighter control and those that may be relaxed to reduce cost.

In STOP workflows, structural models can incorporate these tolerance ranges and simulate their contribution to surface figure deformation. Combined with environmental thermal data, engineers gain a full picture of how real-world variation will impact aerospace optical component performance.

Process Route Evaluation Using Simulation Outputs

Results from STOP and tolerance simulations directly inform the selection of the route in aerospace optical parts manufacturing. Common pathways include:

- CNC machining and polishing: Conventional route for large mirrors and mounts. STOP analysis helps assess stress-induced deformation during polishing or thermal soak, guiding material and support structure design.

- Additive manufacturing (AM): Simulations model residual stress and distortion during build and cooldown phases. These inform whether post-process machining can bring the optic within spec.

- Glass molding: Suitable for replicated optics and aspheres, provided surface deformation and birefringence remain within acceptable limits. STOP analysis can model thermal cycles to ensure final surface shape integrity.

- Diamond turning: Often used for IR optics and metal substrates. Mechanical compliance and thermal behavior under tool loads are simulated to ensure surface precision and mitigate mid-spatial frequency errors.

Model Validation and Certification Support

Validated STOP models can reduce the scope and frequency of environmental testing in aerospace optical components. Oudijk et al. (2023) demonstrated that STOP analysis accurately predicted the thermal-vacuum behavior of a CubeSat hyperspectral imager. This validation supported its use in qualification documentation and alignment planning. Such models also contribute to optical and mechanical budgets for flight certification and anomaly resolution.

Aerospace Optical Manufacturability & Certifiability: In Conclusion

Simulation-based design-for-manufacture strategies improve robustness, manufacturability, and certifiability of aerospace optical systems. STOP and tolerance stack-up analyses offer predictive insights across thermal, structural, and optical domains. By embedding these methods early and iteratively into the development process, engineers can reduce design cycles, ensure compliance, and confidently select optimal manufacturing routes.

Bolognese, J., & Irish, S. (2015, August). Structural-Thermal-Optical-Performance (STOP) Analysis. TFAWS 2015. NASA GSFC. Visit source.

Oudijk, A. E., Navarro-Medina, F., Henriksen, M. B., Garcia-Luis, U., Gomez-San Juan, A., & Johansen, T. A. (2023). Structural thermal optical performance (STOP) analysis and experimental verification of a hyperspectral imager for the HYPSO CubeSat. NTNU Open. Visit source.

Siew, W. (2020). Monte Carlo Simulation and Analysis in Modern Optical Tolerancing. SPIE Press. Visit source.

Wang, L., Liu, J., & Chen, Y. (2020). Mid-spatial frequency reduction via zero-depth of cut rapid-feed passes in single-point diamond turning. Precision Engineering, 65, 132–139. Visit source.

Zhang, Y., & Chen, Y. (2025). Rapid residual stress simulation and distortion mitigation in laser additive manufacturing. Additive Manufacturing, 38, 101771. View source.