Discover how Ansys Twin Builder revolutionizes simulation by enabling real-time digital twins and performance benchmarking for cutting-edge applications.

Unlocking the Power of Digital Twins with Ansys Twin Builder

Digital twins are transforming the way industries approach system design, maintenance, and optimization. With Ansys Twin Builder, organizations can construct real-time digital replicas of physical assets, unlocking new possibilities for predictive maintenance, operational efficiency, and rapid troubleshooting. This technology integrates data from sensors and control systems, delivering actionable insights that drive informed decision-making across the asset lifecycle.

By leveraging Ansys Twin Builder, engineering teams can simulate complex multiphysics interactions in real time, validate control strategies, and optimize system behavior before deployment. This not only reduces downtime but also extends asset lifespan and enhances reliability, addressing the increasing demands for operational excellence in capital-intensive sectors such as mining, energy, and manufacturing.

Key Features that Set Ansys Twin Builder Apart

Ansys Twin Builder stands out with its robust support for reduced order modeling (ROM), enabling high-fidelity simulations to be executed with unprecedented speed. Its seamless integration with leading engineering tools—including MATLAB, Python, and OPC UA—facilitates the creation of comprehensive simulation workflows that mirror real-world processes, enhancing accuracy and adaptability.

The platform’s ability to connect virtual models to live operational data supports advanced digital twin and predictive maintenance workflows. Twin Builder offers a library of pre-built components and supports custom scripting, allowing for scalable, enterprise-grade simulation solutions tailored to unique industry requirements. Automated validation, data-driven optimization, and cross-domain multiphysics capabilities further differentiate Ansys Twin Builder as a leader in digital twin technology.

The Digital Twin Engineering Solution

Ansys Twin Builder, supported by SimuTech Group’s simulation consulting expertise, offers comprehensive solutions to these challenges. By combining advanced simulation technologies with industry-specific workflows, our teams streamline model development, data integration, and validation processes, ensuring rapid and reliable deployment of benchmark applications.

Our engineering approach emphasizes robust project management, iterative validation, and compliance with industry regulations. Tailored consulting, hands-on training, and ongoing technical support ensure that teams can maximize the value of their digital twin investments, from initial concept through long-term operation.

Benchmark Application: Golden Gate Bridge Digital Twin

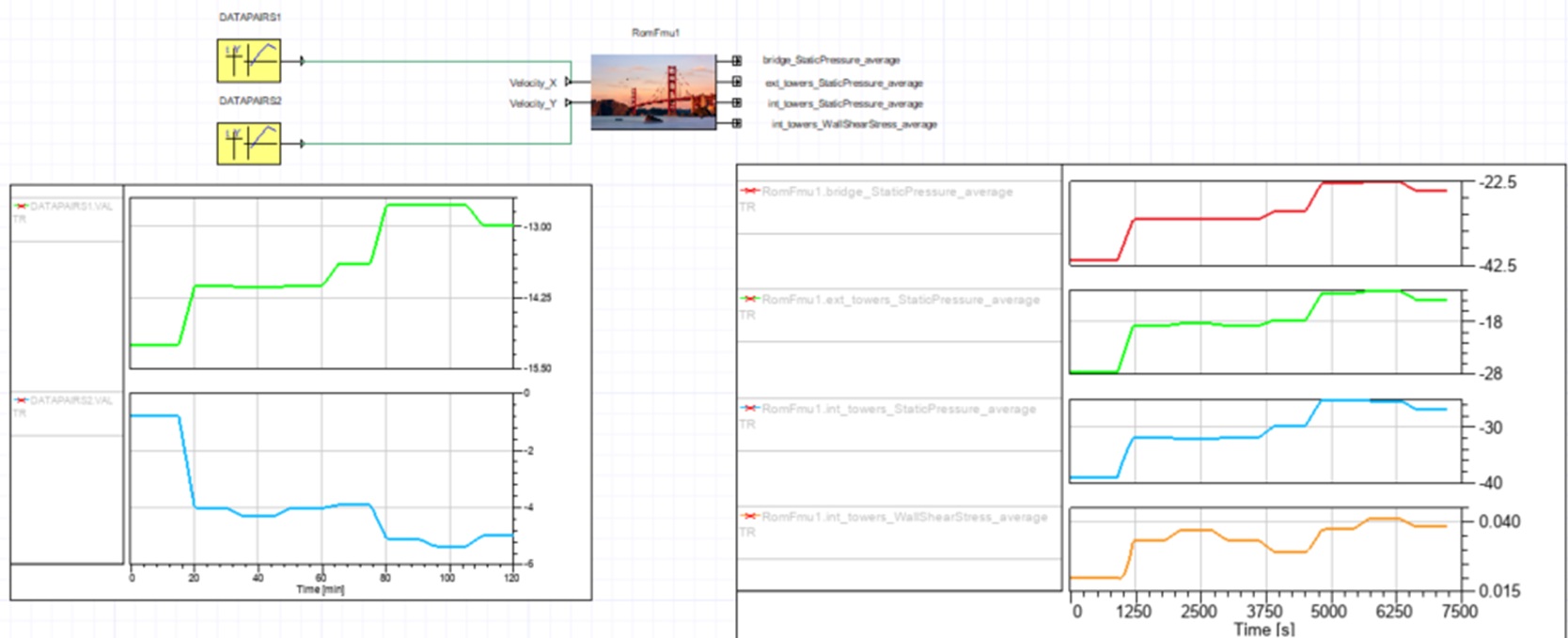

The process of building a benchmark application with Ansys Twin Builder begins with defining the system architecture and identifying key performance indicators (KPIs). Model components are then developed or imported, leveraging Twin Builder’s extensive libraries and ROM capabilities to ensure both accuracy and computational efficiency.

In this benchmark application, a digital twin of the Golden Gate Bridge was developed. The step-by-step workflow was presented in consecutive videos.

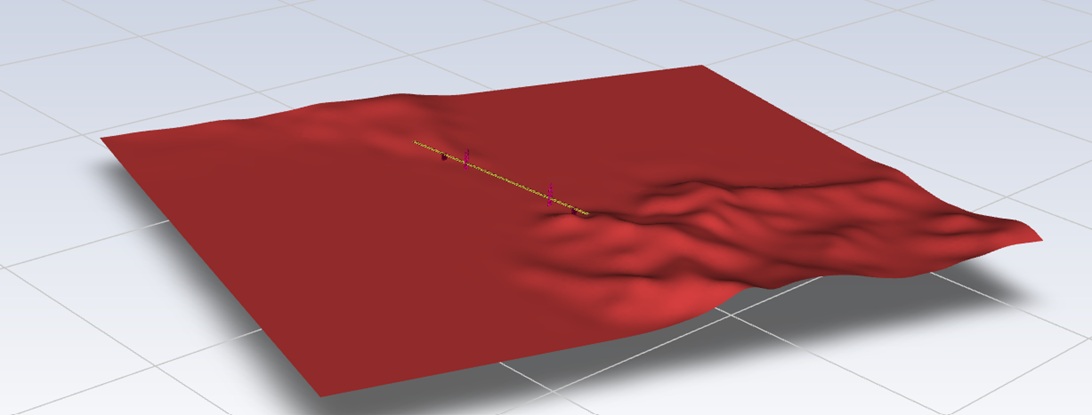

Part 1: Generating the model of the bridge and surroundings with Ansys Fluent, determining the model inputs and outputs and reduced order model (ROM) generation.

Part 2: Importing the generated ROM to Ansys Twin Builder and setting up the features to create the twin.

Part 3: Reading the live weather data, feed into the twin, and obtain the outputs.

Ansys Twin Builder: Benefits & Next Steps

Ansys Twin Builder empowers engineers to create high-fidelity digital twins that combine physics-based simulation with live operational data, enabling real-time monitoring, predictive maintenance, and system performance optimization. These capabilities reduce downtime, enhance model accuracy, and extend the lifecycle of critical assets.

In the Golden Gate Bridge benchmark application, Twin Builder was used to integrate aerodynamic simulation data, reduced order models, and real-time weather inputs—allowing engineers to analyze structural responses under varying wind conditions and continuously validate system behavior. This approach demonstrates the platform’s ability to deliver actionable insights for large-scale infrastructure through scalable, data-driven digital twin workflows.

Turn your digital twin into a real-time decision tool

Ready to move from high-fidelity simulation to live, real-time insights? Talk with SimuTech Group about building a digital twin workflow in Ansys Twin Builder—complete with ROMs, live data inputs, and KPI-driven performance benchmarking.

Ertan Taskin, Ph.D., Chemical Engineering

Principal Engineer, SimuTech Group

Ertan is a Principal Engineer with more than two decades of experience in CFD, fluid-structure interaction, and biomedical device design. He has advanced ventricular assist devices, transcatheter heart valves, and artificial lungs through hydraulic optimization, in vitro validation, predictive modeling, and AI-driven data analysis. His recent work integrates machine learning for performance prediction and design optimization. His career includes senior engineering roles at Medtronic, HeartWare, Roketsan, and Ozen Engineering, where he led projects spanning medical devices and aerospace propulsion. Ertan’s expertise includes blood damage modeling, uncertainty quantification, integrated thermo-fluid systems, and AI-assisted simulation workflows. He holds a Ph.D. in Chemical Engineering from Worcester Polytechnic Institute, along with Master’s and Bachelor’s degrees in Chemical Engineering from Middle East Technical University.