Background

Horst Welding (www.horstwelding.com) is known for its aftermarket product to support the construction and agricultural industry. Their reputation is such that they are recommended by the OEM of the equipment. Always wanting to improve their product, Horst Welding decided to perform finite element analysis (FEA) simulations, as a structural comparison, of their SB4000DMKUM110 undercarriage tractor mount that is used on a Kubota tractor.

Structural Comparison Challenge

Horst Welding was interested in performing a relative structural comparison between their existing design and a newly developed concept. Of particular interest was the optimization in the load transfer to the Kubota tractor. It was recognized that a physical prototype would be expensive and take significant time to build and perform field testing.

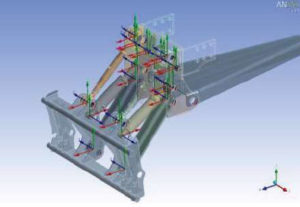

Detailed finite element models of the designs were constructed utilizing the advanced engineering software Ansys.

Solution

SimuTech Group was employed to perform FEA simulations of the two designs to obtain relative comparisons. Detailed finite element models of the designs were constructed utilizing the advanced engineering software Ansys. Its capabilities in combining rigid and flexible bodies in combination with joints were particularly useful in representing the mechanical behavior of the assembly.