Electronic products are devices that utilize electrical energy to perform various tasks or functions. These products are a crucial part of modern life and serve various industries from consumer and automotive, to healthcare, aerospace, and defense.

As electronic products grow increasingly complex, it is important to ensure these products meet the highest standards of reliability. Electronics reliability is critical for all industries and technology trends, but it is especially impactful for small and medium-sized businesses. Maintaining high standards of electronics reliability can:

- Accelerate time-to-market

- Improve first-pass yield

- Increase the number of new product features

- Decrease warranty rate

Ansys simulation solutions give engineers the ability to address and achieve these standards while realizing numerous additional benefits.

Areas to consider when designing for Electronics Reliability:

- Component Selection

The reliability of an electronic product depends on the quality and selection of the components used. It is important to select the components that meet the required quality standards and are suitable for the application. - PCB Layout

The PCB layout plays a critical role in the reliability of the electronic product. A well-designed PCB layout not only ensures the proper functioning of the product but also improves its reliability. The PCB layout should be designed to reduce the possibility of issues such as electromagnetic interference (EMI) and crosstalk.Development teams can analyze various design configurations and optimize them for EMI/EMC compliance quickly and accurately with Ansys simulation solutions. - Thermal Management

The reliability of the electronic product can be affected by thermal stress or overheating. The proper thermal management of the electronic product is essential to ensure its reliability. As an Electronics Engineer, it is essential to design the product in such a way that its temperature remains within the safe operating limit.

- Test Plan

The electronic product’s reliability can be improved by implementing a comprehensive test plan that covers all aspects of the product. The test plan should include tests for each component, subsystem, and full system operation. - Compliance with Standards

Compliance with relevant standards is critical for electronic product reliability. The product should be designed and tested to meet the relevant standards, such as CE, FCC, and RoHS - Field Failure Analysis

To improve the electronic product’s reliability, it is important to analyze the field failures and take corrective actions. Simulation can help identify failure and inform corrective actions quickly, thus saving prototyping costs.

Engineers can test for major causes of electrical failure (thermal, mechanical and electrical stress) and make quick design changes to improve reliability with Ansys Electronics Reliability (ER), a dedicated multi-physics, multi-tool solution. The ER workflows currently feature Mechanical, LS-DYNA, Sherlock, and Icepak integrations. This comprehensive Electro-Thermo-Mechanical Reliability workflow can improve product reliability and operational performance while addressing the challenges of modern electronics systems.

Electronics Reliability Challenges Addressed

- Electrical ReliabilityUnlock the ability to optimize overall system performance, improve signal and power integrity. improve antenna performance, and minimize EMI risk. With a fully couped system, connections can be made with thermal and mechanical reliability solutions.

- Thermal ReliabilityUnderstand thermal impact on electrical and mechanical reliability. A comprehensive electro-thermal and thermo-mechanical workflow helps address thermal management at multiple scales, thus enabling enhanced cooling strategies, improved product reliability, and decreased product development time.

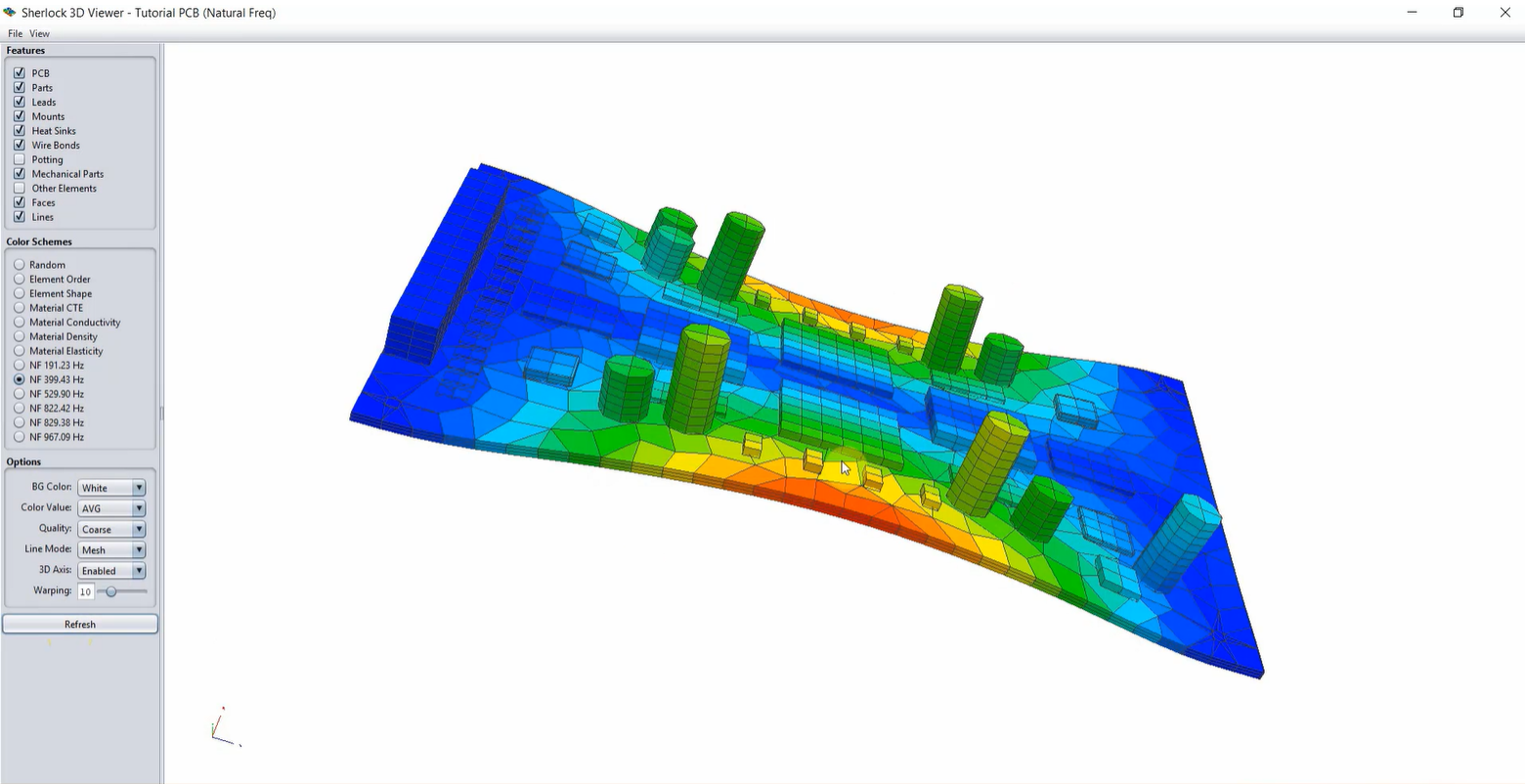

- Mechanical ReliabilityNonlinear materials, detailed traces, and vias modeling using reinforcements, enable engineers to model trace effects, solder fatigue, and assembly stress effects, evaluate performance under environmental conditions and duty cycle, and simulate product durability such as shock and drop events.

- Comprehensive MultiphysicsAddress thermal demands with miniaturization of electronics, reduce cost of cooling hardware selection, and mitigate the risks for system integration with multidomain, multiscale system level evaluation. Seamless and intuitive workflows allow end-to-end validation across various domains using seamless and intuitive workflows.

- Reliability Physics AnalysisSee 20-50% time reduction in PCB reliability prediction at component, board and system levels. Ansys simulation solutions can help engineers reduce costs for various industry standards by reducing physical prototypes by ~50%.

Electronic products play a crucial role in our daily lives and serve various industries, providing convenience, efficiency, automation, and more. Electronic product reliability is essential to ensure consumer safety and customer satisfaction. Ansys simulation software for electronics reliability ensures product safety, performance, and cost-control across multiple physics and scales.

Sound like a project your team is working on? Contact us today for any of your consulting, training, mentorship, or physical testing needs.