Your trusted partner for over 25 years.

partner for over 25 years.

Multiphysics Simulation for Automotive

Engineering Confidence Into Every Design Decision

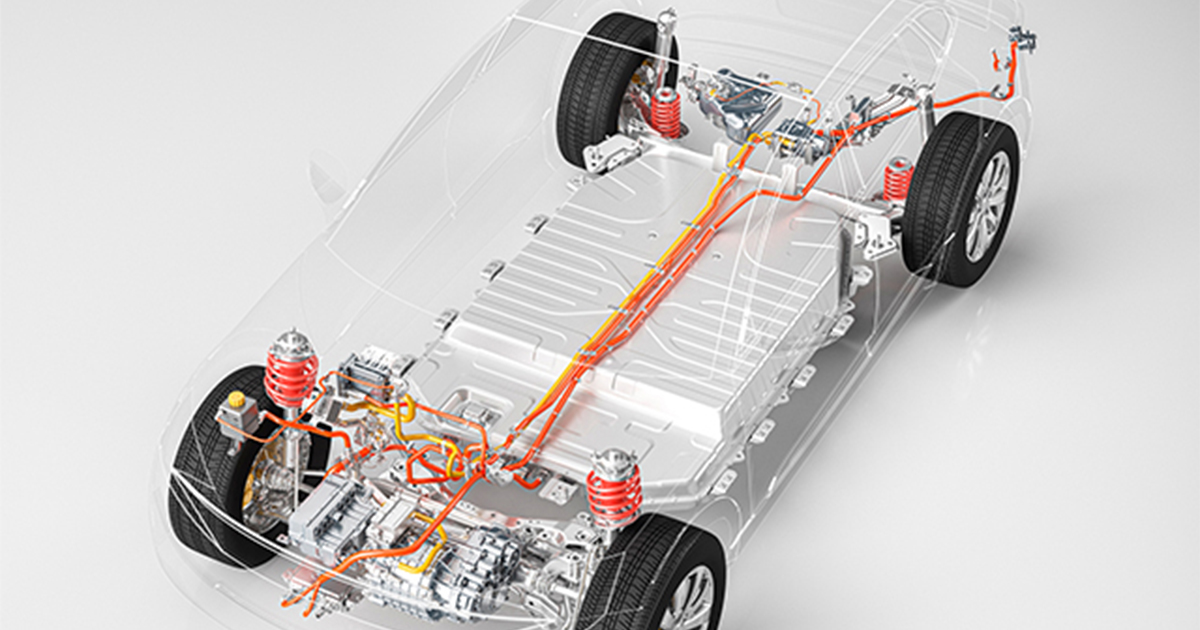

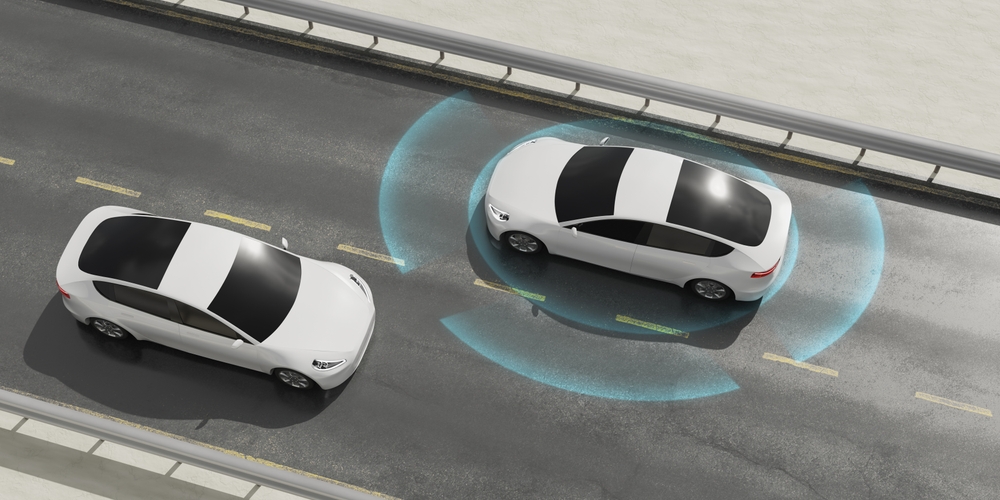

Modern EVs and autonomous systems demand tight control over battery safety, motor efficiency, power electronics reliability, and sensor performance. These interconnected challenges leave no room for guesswork. Ansys delivers the multiphysics accuracy engineers need to solve issues early—optimizing thermal behavior, electromagnetic integrity, and vehicle efficiency using tools like Motor‑CAD, HFSS, and Fluent. The result: fewer prototypes, reduced risk, and faster delivery of safer, smarter vehicles.

The Roadmap to Next-Gen Mobility

Engineering Simulation: The Future of Automotive Innovation

As the automotive industry experiences disruption in areas of technology, competition, regulation and shifting consumer demand, engineering simulation leads the way in delivering the highest level of competitive advantage and proven return on investment.

Design high-efficiency traction motors and integrated e-drives.

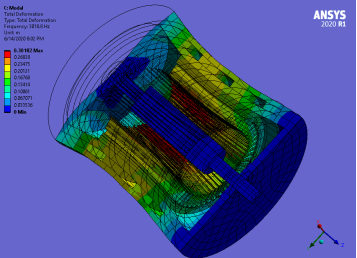

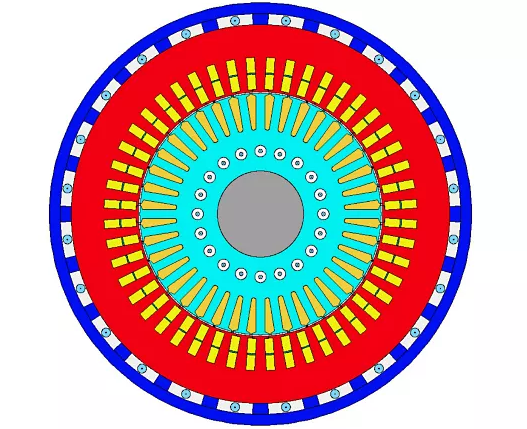

Ansys Motor-CAD

Electric powertrains demand rapid iteration across electromagnetic performance, thermal limits, and mechanical constraints. Ansys Motor-CAD enables fast, accurate electric machine design exploration—helping engineering teams optimize torque, efficiency, and temperature rise while reducing reliance on prototype-heavy development cycles.

- Optimizes motor torque, efficiency maps, and loss breakdowns early in the design process

- Evaluates thermal behavior and cooling strategies to support performance and reliability targets

- Accelerates design trade studies and reduces prototype loops for faster program timelines

Predict EMI/EMC risk and validate high-voltage electronics performance.

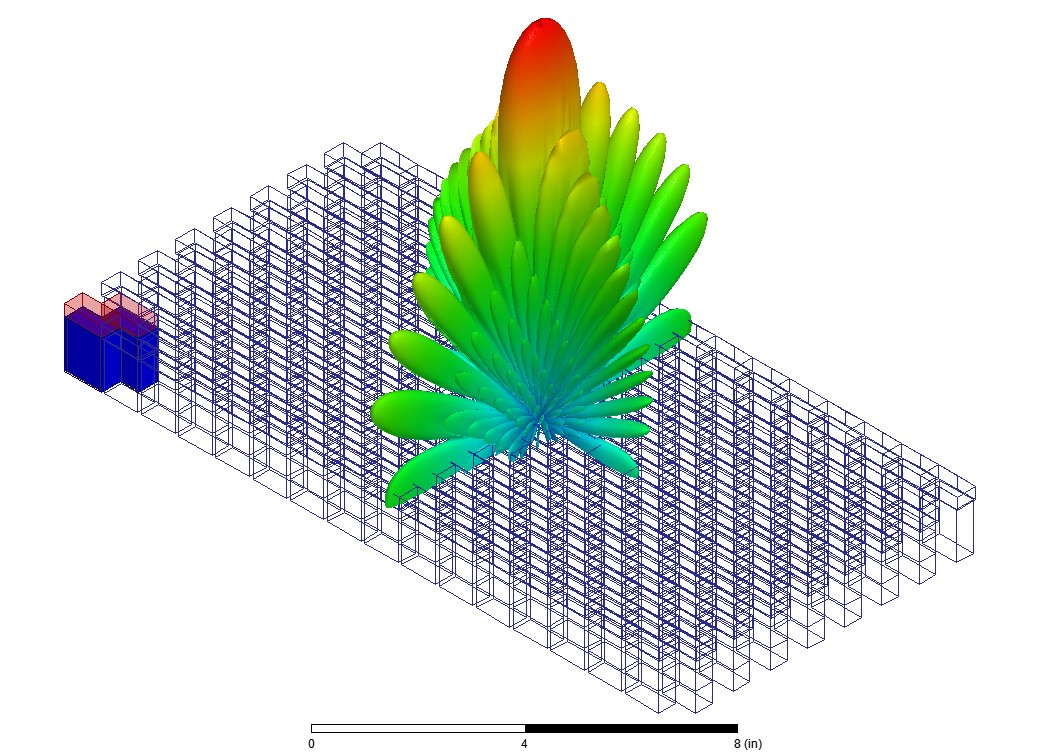

Ansys HFSS

As vehicle electronics density grows, electromagnetic interference can disrupt radar, antennas, and high-speed signal integrity—especially in EV architectures with high-voltage switching. Ansys HFSS provides high-fidelity 3D electromagnetic simulation to uncover interference early, improve EMC performance, and strengthen reliability across critical electronic systems.

- Delivers 3D full-wave EM simulation for antennas, radar components, cables, and interconnects

- Supports EMI/EMC analysis to identify coupling, noise sources, and susceptibility risks sooner

- Optimizes RF performance and electromagnetic integrity across ADAS and connected systems

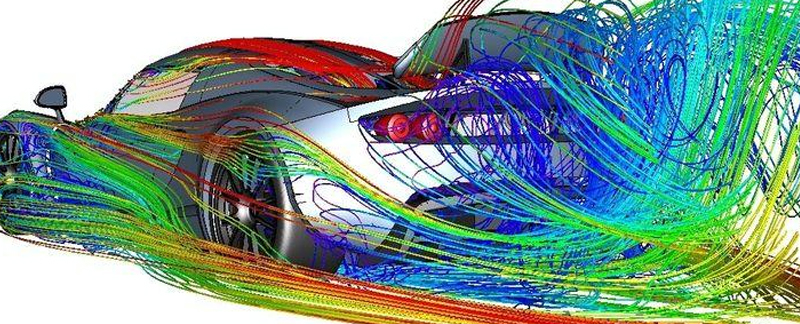

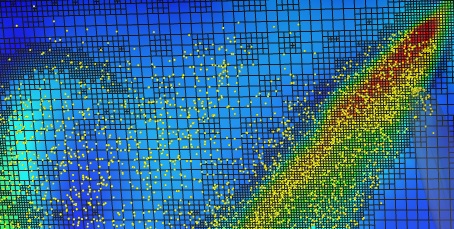

Optimize thermal performance across the vehicle—from battery to airflow.

Ansys Fluent

Thermal performance impacts EV range, durability, and safety across batteries, power electronics, and cabin/underhood systems. Ansys Fluent delivers advanced CFD and thermal simulation to evaluate cooling strategies, improve airflow and aerodynamics, and model battery safety scenarios—enabling smarter decisions earlier in development.

- Models battery cooling performance and thermal runaway behavior to support safety-focused design

- Improves aerodynamic efficiency and thermal airflow management across full-vehicle conditions

- Supports thermal system integration and design validation with fewer physical iterations

Where We’ve Helped

OEMs and suppliers trust SimuTech Group to engineer safer, more efficient vehicles — from electrified powertrains and battery safety to EMI/EMC, thermal management, and ADAS validation.

Related Resources

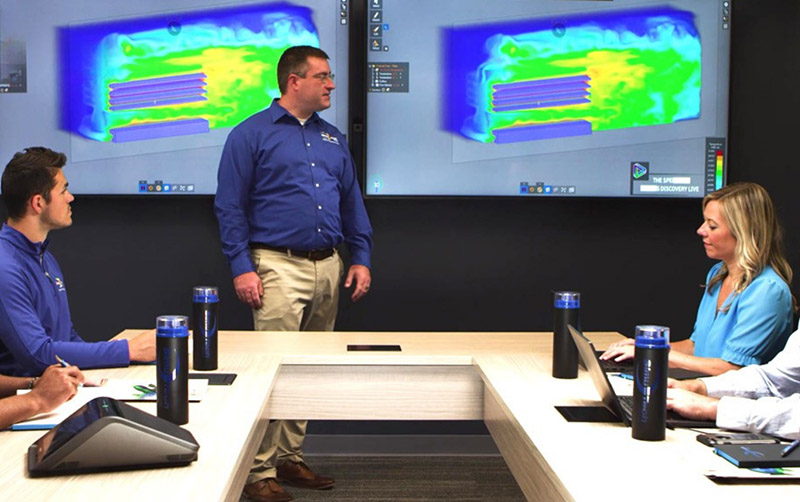

Your Full Service Partner

Ansys Software

We are North America’s #1 Ansys partner, delivering expert sales, support, and software integration for our clients.

Simulation Consulting

We have over 25 years experience with solving complex engineering challenges with our deep simulation and domain expertise.

Training & Mentoring

We provide hands-on Ansys and simulation training led by our engineers, tailored to real-world applications and industry needs.

Physical Testing Services

We diagnose machinery faults, support failure investigations, and validate modeling parameters with advanced engineering testing.

Ready to Accelerate?

Rising thermal, electronics, and safety demands require fast, accurate validation. Ansys simulation reduces prototypes and accelerates confident design decisions. Connect with our experts to advance your next‑gen mobility roadmap.

![auto-battery-background-e1768780112651[1]](https://simutechgroup.com/wp-content/uploads/2026/01/auto-battery-background-e17687801126511.png)