Introduction

The medical technology (medtech) industry is under constant pressure to deliver safer, more effective devices at an accelerated pace. With growing regulatory requirements, rising development costs, and increasing demand for personalized solutions, traditional design and testing methods often fall short. This is where simulation steps in as a transformative tool—enabling virtual prototyping, predictive modeling, and data-driven decision-making that streamline development and reduce risk.

Why Medical Simulation Matters

Simulation allows engineers and researchers to create digital models of devices, biological systems, and clinical environments. These models can be tested under a wide range of conditions without the need for costly physical prototypes. By leveraging computational power, medtech companies can:

- Shorten Development Cycles: Virtual testing identifies design flaws early, reducing the number of physical iterations.

- Lower Costs: Fewer prototypes and less reliance on animal or human trials translate into significant savings.

- Improve Safety and Efficacy: Simulations predict device performance under real-world conditions, helping ensure patient safety.

- Support Regulatory Submissions: Digital evidence is increasingly accepted by regulatory bodies, complementing traditional testing.

- Attain Deeper Insight: Simulation reveals detailed field behavior throughout tissues and devices—insights that are difficult or impossible to measure directly in physical testing.

Accelerating Regulatory Approval

Regulatory agencies are increasingly recognizing the value of simulation in demonstrating safety and efficacy. Digital evidence can complement bench testing and clinical data, creating a more robust submission package. For example, simulations can validate:

- Implantable defibrillators under extreme electrical loads.

- Endoscopic tools in scenarios that would be impractical or unethical to replicate in real life.

This not only speeds up approval but also builds confidence in innovative designs.

Like what you’re reading? Watch the on-demand webinar.

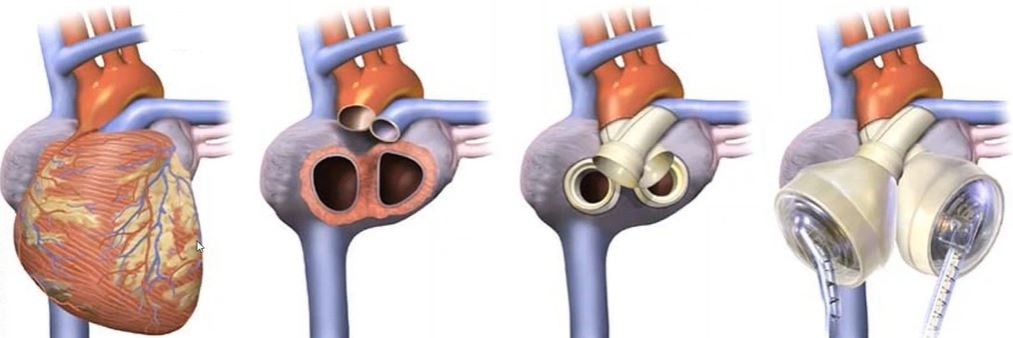

See our engineers build and analyze real CFD and electromagnetic models in “Developing Biomedical Devices with Ansys CFD and Electromagnetic Simulations.” Watch on-screen as they simulate blood pumps and artificial kidneys, explore patient-specific airway flow, and use the Ansys human body model to evaluate device performance and safety.

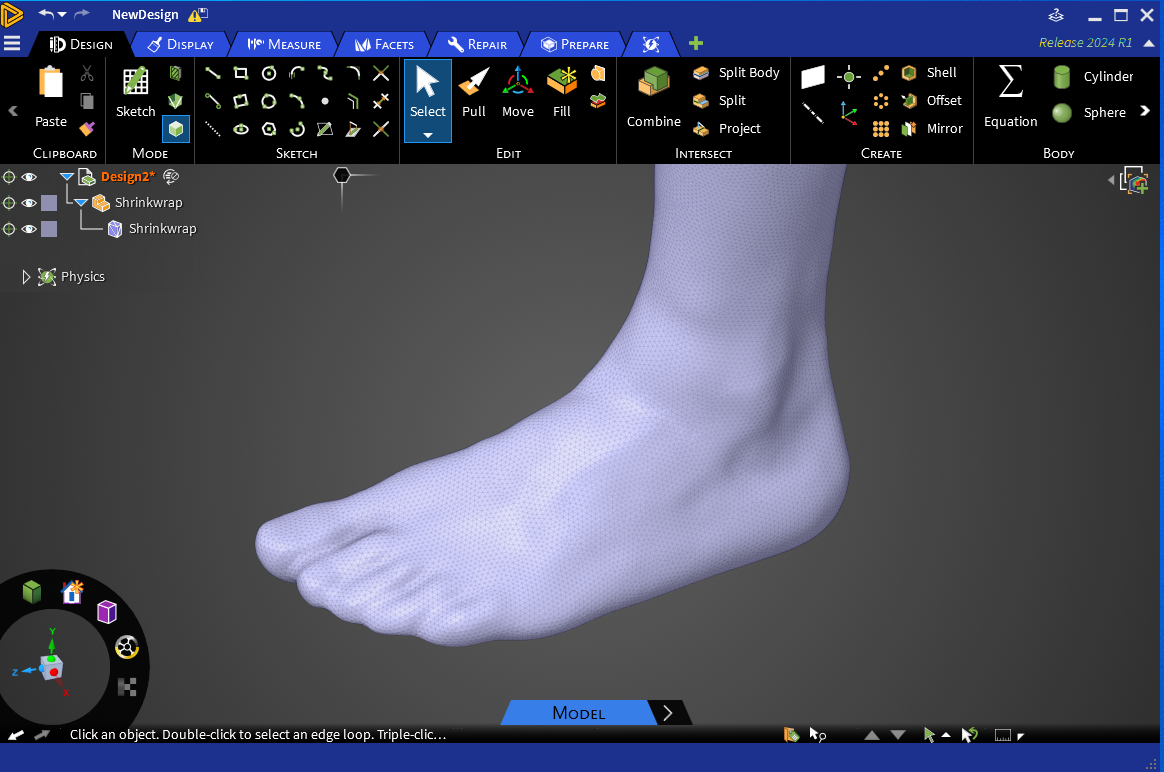

Enabling Personalized Medicine

As healthcare moves toward personalization, medical simulation plays a pivotal role. Patient-specific models allow devices to be tailored to individual anatomy, improving outcomes and reducing complications. For instance:

- Custom orthopedic implants can be designed using simulations based on imaging data.

- 3D-printed surgical guides can be optimized for precision placement during complex procedures.

Medical Simulation Applications Across the MedTech Product Lifecycle

Simulation is not limited to a single stage of development—it can be applied throughout the entire product lifecycle, from concept design to post-market analysis. By integrating simulation early and often, medtech companies can uncover insights that traditional testing might miss, reduce costly redesigns, and accelerate innovation. Below are some of the most impactful areas where simulation is driving change:

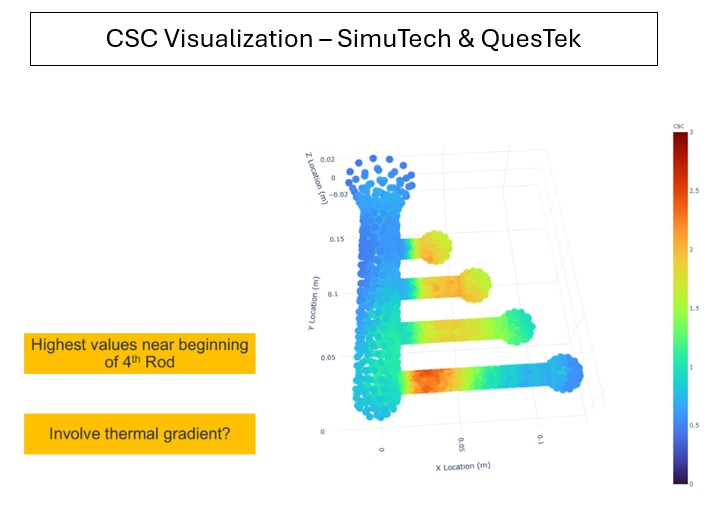

Design Optimization: Simulation enables engineers to refine device geometry, material properties, and mechanical performance before manufacturing begins. For example:

- Cardiovascular stents can be virtually tested for fatigue resistance and flexibility under pulsatile blood flow.

- Hip and knee implants can be analyzed for stress distribution and wear patterns, ensuring durability and patient comfort.

- Insulin pumps can be modeled to optimize housing design and internal mechanisms for reliability.

Biomechanical Modeling: Advanced simulations replicate human anatomy and physiology, allowing devices to be tested in patient-specific contexts. For instance:

- Spinal implants can be evaluated for load-bearing capacity across different vertebral structures.

- Cranial plates can be tested for impact resistance and anatomical fit using CT-based models.

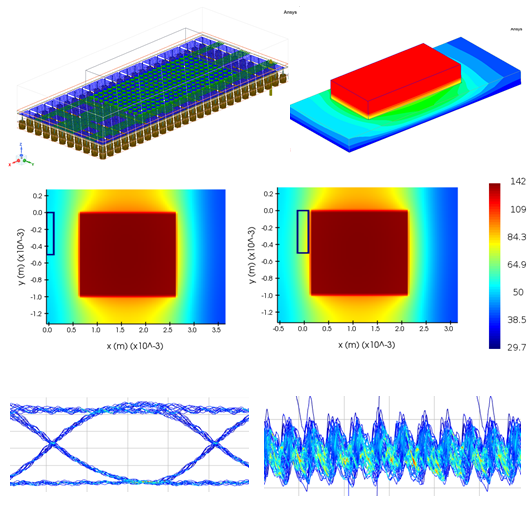

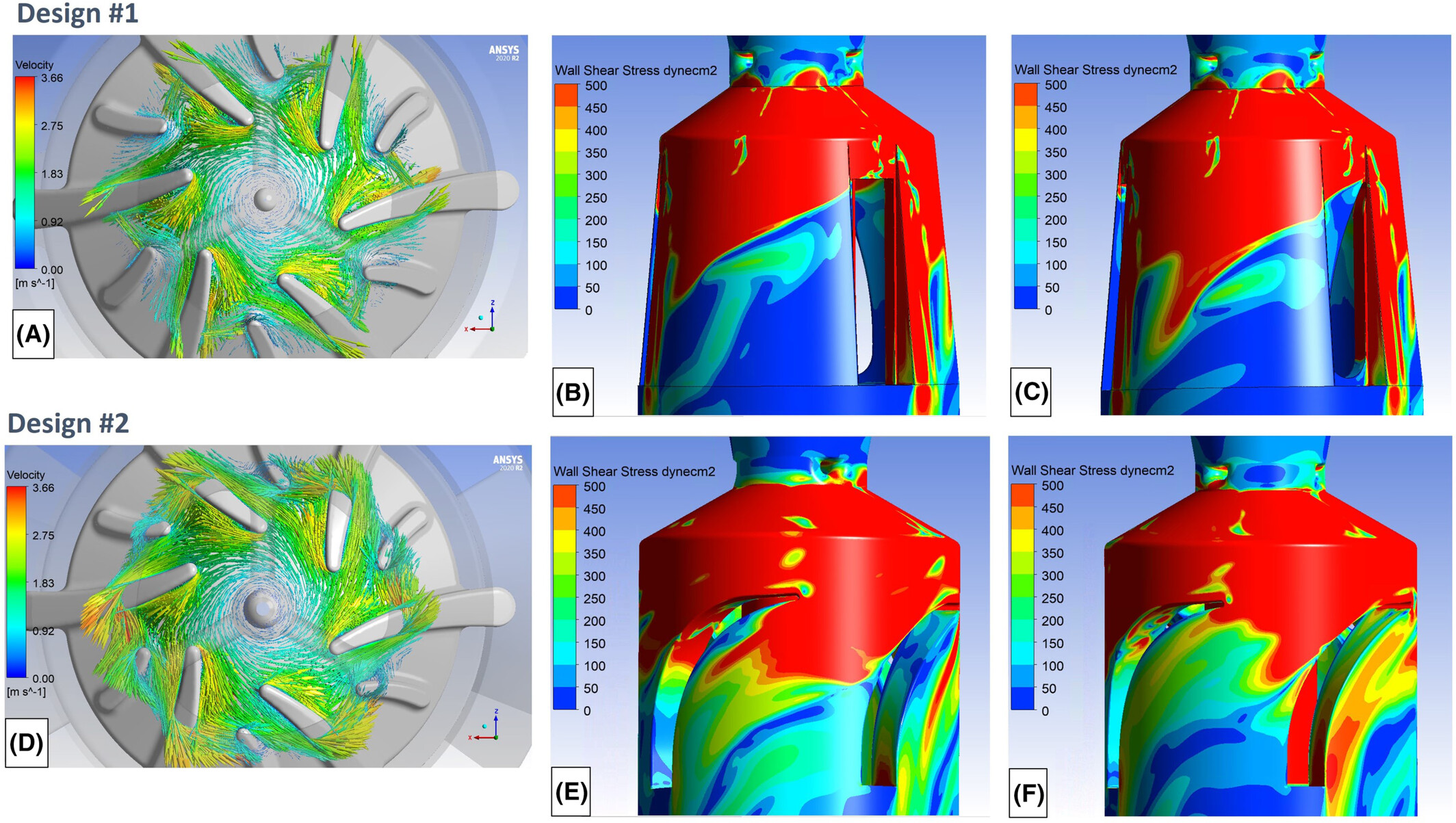

Fluid Dynamics: Drug Delivery Devices such as inhalers or infusion pumps rely on precise fluid mechanics. Computational fluid dynamics (CFD) simulations predict:

- How aerosolized drugs disperse within the lungs for inhalers.

- Flow rates and pressure variations in dialysis machines or catheters, improving dosing accuracy and patient safety.

Thermal and Electrical Analysis: For devices like surgical tools or diagnostic sensors, heat generation and electrical performance are critical. Simulation helps predict:

- Thermal effects during laser surgery, reducing the risk of tissue damage.

- Electrical conductivity and signal integrity in cardiac pacemakers or neurostimulators.

Virtual Clinical Trials: One of the most promising applications is the use of in-silico trials—computer-based simulations of patient populations. These trials can model thousands of virtual patients, providing insights into device performance across demographic and anatomical variations. For example:

- Heart valve replacements can be tested across different age groups and comorbidities.

- Wearable glucose monitors can be evaluated for accuracy under varying physiological conditions.

Challenges and Future Outlook

While the benefits are clear, implementing medical simulation best practices in medtech development requires overcoming challenges such as:

- Data Quality: Accurate simulations depend on high-quality input data from imaging, material properties, and clinical studies.

- Computational Resources: Complex models demand significant computing power, though cloud-based solutions are making this more accessible.

- Regulatory Alignment: Continued collaboration between industry and regulators is essential to standardize simulation methodologies and validation protocols.

Looking ahead, advancements in artificial intelligence and machine learning will further enhance simulation capabilities. AI-driven models can predict outcomes faster and with greater accuracy, while integration with real-world data will create dynamic, adaptive simulations that evolve throughout the product lifecycle.

Medical Simulation & the Future of Healthcare

Simulation is no longer a supplementary tool—it is becoming a cornerstone of medtech innovation. By enabling faster design iterations, reducing costs, and supporting regulatory compliance, simulation empowers companies to deliver safer, more effective devices to patients worldwide. As technology continues to evolve, its role in shaping the future of healthcare will only grow stronger.