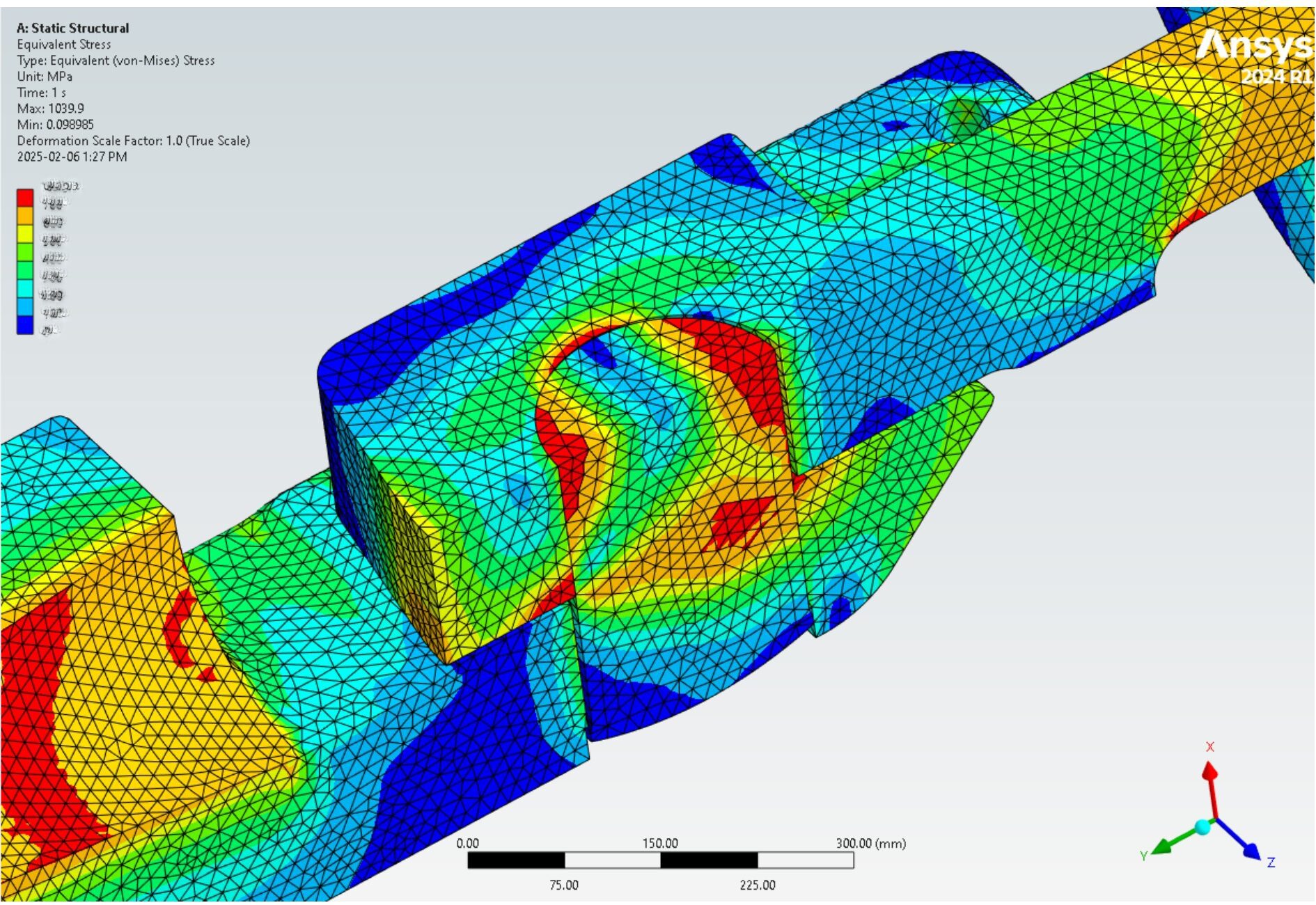

FEM Modeling Approaches of Bolted Connections

Many methods are available to model bolts. What are the best ways Ansys simulation software can help engineers with bolt simulation, and how might an engineer best approach modeling bolted connections.

Ansys Mechanical Workbench Topics Covered:

In this recorded webinar, SimuTech Group shares our expertise using Ansys Workbench™ in models that:

- Use bonded contact to attach the parts (bolts not included)

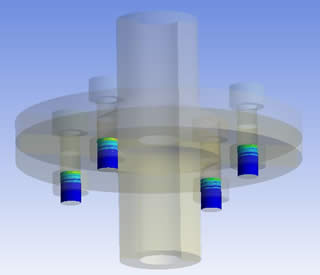

- Use beam elements to model the bolts

- Use solid elements to model the bolts but do not model the threads

- Include the threads in modeling

Related Software for FEM Bolted Connections:

ANSYS Workbench | Tactics for developing bolted connections

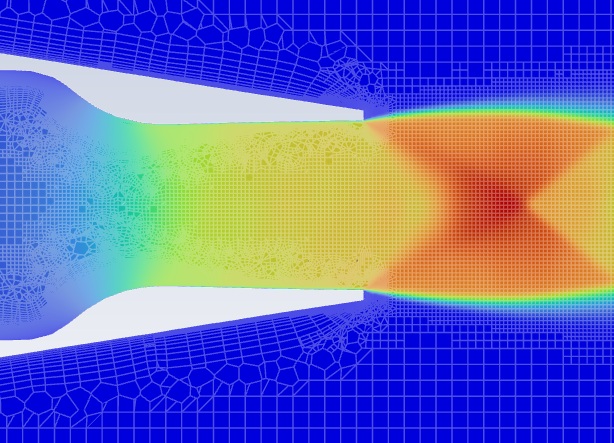

Expanded Read

One of the core obstacles for engineers that are new to the simulation world, is that there are often many decisions that need to be made by the engineer, that trades off the accuracy of the simulation versus computation efficiency.

It can take many years of experience of both product knowledge and simulation methods to understand where to compromise the simulation model to enable it to be solved in the computational resource available while maintaining a reasonable level of accuracy.

Running with bolted assemblies is one area where this tradeoff is readily evident.

Common Bolt Modeling Questions

- Do you model the whole bolt, with rings and nuts, possible even the thread?

- Or do you use some level of generalization, some representation of the bolt, which captures the behavior of the bolted connection. In effect, allowing for a much more efficient solution?

- Our team will review some of the possible approaches closely in our advanced webinar training.