Background

MSE Technology Applications Inc. specializes in providing engineering management, and technical support services to public and private sector. One of their specialties is the design and operation of mobile demilitarization systems for the disposal of out of date and recovered ordnance.

MSE-TA has designed a new mobile system that will be able to dispose of larger ordnance. Although the design is like their existing designs, the chamber is larger and needs to withstand larger explosions. Work was performed for the U.S. Department of Defense.

Challenge

The production of a blast chamber and associated components is extensive and so testing of multiple design iterations is not very feasible. Computer simulation was required to validate a design before a prototype is produced.

The simulation is highly complex due to several factors. The speed of the event requires very small-time steps. The interaction between the solid, liquid, and gas regions is difficult to capture.

Solution

The customer’s CAD model was imported into Ansys Workbench. The geometry was processed with Design Modeler. Ansys simulation was used to create a finite element mesh of the model which was imported directly into AUTODYN.

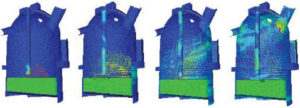

AUTODYN was used to set up the initial conditions and interfaces between the fluid, solid, and shell regions. The extensive material library provided by AUTODYN was also very useful for some of the standard materials. Simulations of blasts at various locations inside the chamber predicted that it will be capable of withstanding explosions. Regions with higher stresses were noted for possible design improvements.

To create this simulation, SimuTech Group used AUTODYN, an explicit solver that specializes in explosions and hyper-velocity impacts.

![]()