Background

MultiDrain® Systems is a manufacturer and distributor of pre-engineered trench drain systems. Products include the EconoDrain® EPS forming system, EconoDrain PT-3™ heavy-duty trench drain system. In addition, MultiDrain® steel trench drain, and Alfa Channel® polymer concrete trench drain. To enhance productivity and mitigate design costs, the team contacted SimuTech Group to conduct a deformation plasticity analysis.

Prior to investment in prototype construction and physical testing, MultiDrain® utilizes FEA services to assure compliance with regulatory conformance to AASHTO, DOT, FAA, Military and “Euro” specifications.

Engineering Challenge | Large Deformation Plasticity Analysis

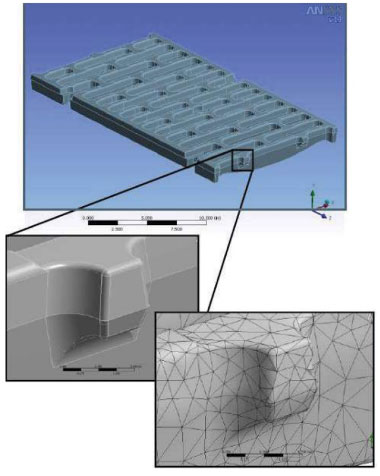

Perform large deformation plasticity analysis with detailed CAD geometry in a timeframe allowing for design iterations.

In addition, the CAD geometry consists of very small features compared to global dimensions, making meshing a challenge.

Solution | Ansys Workbench Plasticity Simulation

An advanced meshing algorithm with Ansys Workbench uses state-of-the-art meshing technology from ICEMCFD/AI* Environment to create a uniformly sized mesh, marginalizing insignificant features without the need to manually remove them.

Beyond the grating, we also utilize your service to evaluate total system performance to assure service continuity and life expectations.

– Engineering Manager, MultiDrain® Systems, Inc.