An Introduction to NVH

NVH (Noise, Vibration and Harshness) engineering targets often are very challenging to accomplish. In the past, there has been heavy reliance on NVH testing of prototypes which no doubt was expensive in a product life cycle. Hardly, any time was devoted to conducting an NVH simulation. Today, the scenario seems to be reversed with focus on NVH simulation entirely. With significant advancements in Ansys NVH engineering in all branches of engineering, structural, CFD, electrical, etc. ; an NVH engineer has several NVH tools at his disposal to solve complex noise and vibration concerns way early in the design phase before any physical prototypes are created. This is indeed great news to cherish!

However, in a field like NVH engineering, especially in noise source identification or control, it would be beneficial for an NVH simulation engineer to incorporate lessons learned from previous or ongoing testing into their simulation. This allows the engineer to not only hone the analysis to conduct an accurate simulation but also to validate it. Ansys has been working very diligently to include test data into a simulation process, with its NVH tool kit. The purpose of this blog is to not only highlight the NVH tool kit but also to briefly extol the beauty of Mechanical Acoustics and Ansys Sound.

NVH Vibration Kit

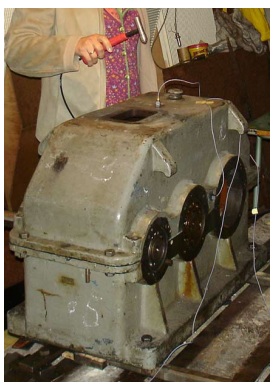

Vibration industries manufacture products often fall into 2 categories, either isolate or dampen vibration with a goal to improvise product durability when operating in dynamic environments. As mentioned above, if you go even to a decade ago, vibration testing was always chosen to be the first step. The reason being vibration testing was done on structural assemblies, and they capture the data in real environment. As an example of modal vibration testing:

Ref: Modal testing of gear box housing, FME Transactions, Vol.35, No.2.108.

The vibration outputs from such modal testing are often Frequency Response Functions (contain amplitude and phase information) and hence Mode Shapes. At that time, if one wanted to make a comparison of the modal test results with modal simulation from Ansys, it would be an arduous task.

Currently in 2025, Ansys Mechanical has an NVH ribbon embedded in its Mechanical GUI:

Three of the above-mentioned NVH tools have established a firm handshake between a vibration simulation engineer and a vibration test engineer. By using the Pre-Test Calculator, a vibration simulation engineer can also guide a vibration test engineer in how to conduct the modal testing, including where to position the sensor and exciter locations for experimental modal testing to effectively capture several modes of importance:

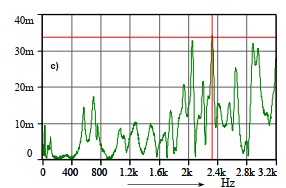

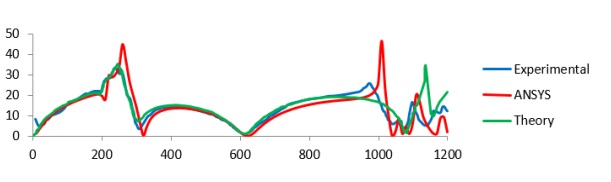

Using the FRF calculator, vibration simulation engineers can simulate the FRFs’ and further compare experimental FRFs’ measured from vibration testing. Here is an example of Accelerance (Acceleration/Force Transfer Function) obtained from Modal simulation for the above gear box assembly:

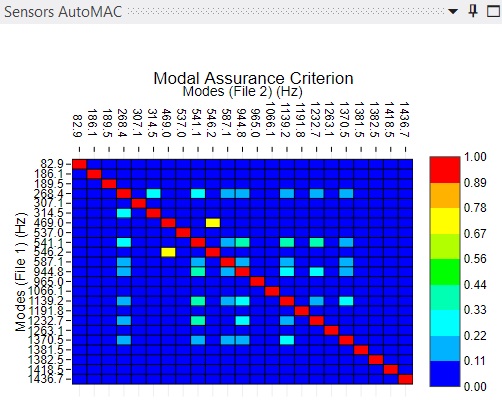

The third NVH tool, Modal Assurance Criterion (MAC) Calculator, checks whether mode shapes obtained from simulation correlate with those obtained from modal testing. This correlation is possible because in Ansys’s MAC, one can easily read the results from Modal testing that are often exported into a universal file format. One can also compare 2 different Ansys simulation results:

Acoustics in Ansys Mechanical

Acoustics is an ocean with a wide range of industry applications. One example application in the automobile industry is minimizing noise radiated from their engines. NVH automobile engineers who are tasked with this goal to minimize the engine noise directly target the source of this noise; one approach followed is to minimize engine vibration. This application is a case of structure-borne inducing noise simulation. Another associated application is design and manufacture of acoustics insulation products specifically for engine dashboards to block or minimize the engine sound to be transmitted into the automobile’s cabin. This application is a case of airborne noise simulation. Another example of airborne noise application is designing exhaust systems with minimum noise emanating from the tail pipe. The acoustics goal of the supplier of the exhaust systems is to meet a state’s noise regulation without reducing the exhaust back pressure.

Ansys’s Mechanical Acoustics can simulate both structure-borne noise and airborne noise. Acoustics testing is often very expensive and time consuming because they involve testing in quiet anechoic chambers. Some of the testing involves a specific type of reverberation rooms that enables one to generate a specific type of diffuse sound input source where sound with equal pressure and probability arrives from all directions. Here are some testing chambers:

Anechoic chamber Ref: ACS Testing Services. Reverberation room Ref: DTU Electro

It should be noted that in any acoustics simulation using Ansys Mechanical Acoustics, one can easily create an anechoic chamber and a diffuse sound input excitation if needed. This is the beauty of simulating in Ansys’s Mechanical Acoustics! Here are few applications:

Muffler Design:

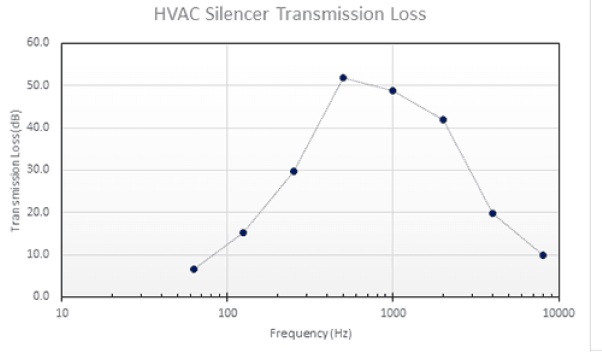

HVAC:

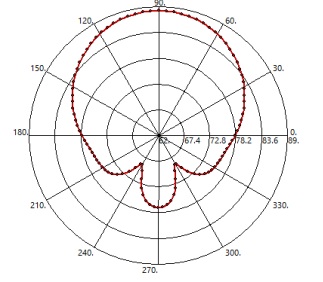

Loudspeaker:

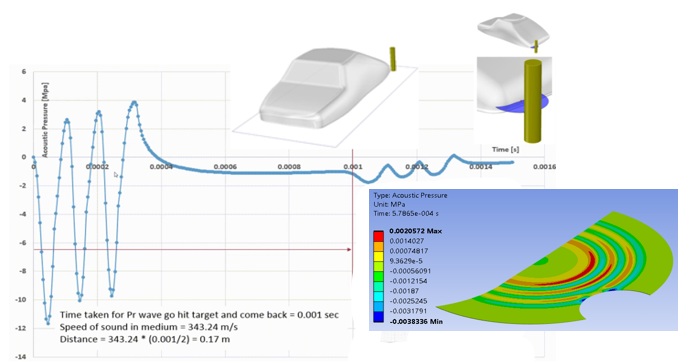

Sensor Detection:

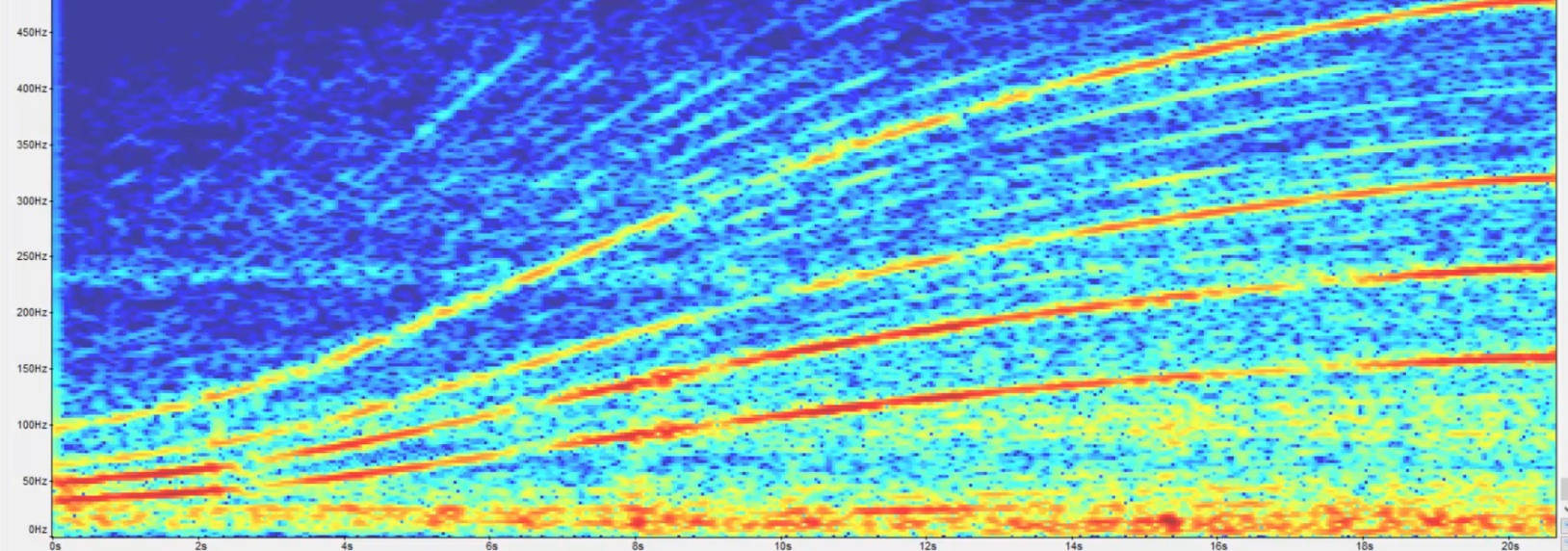

In NVH and acoustics testing, test engineers can deploy advanced measurement equipment and techniques to obtain test results such as acoustics holography for noise source identification, waterfall plots of an engine run up, etc. Similar simulation output results can be obtained in Ansys:

Holography:

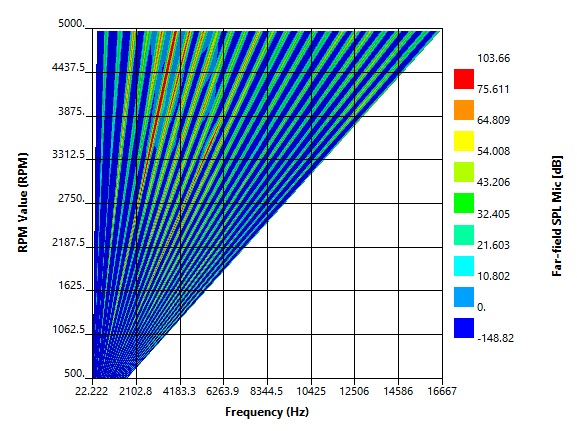

Waterfall:

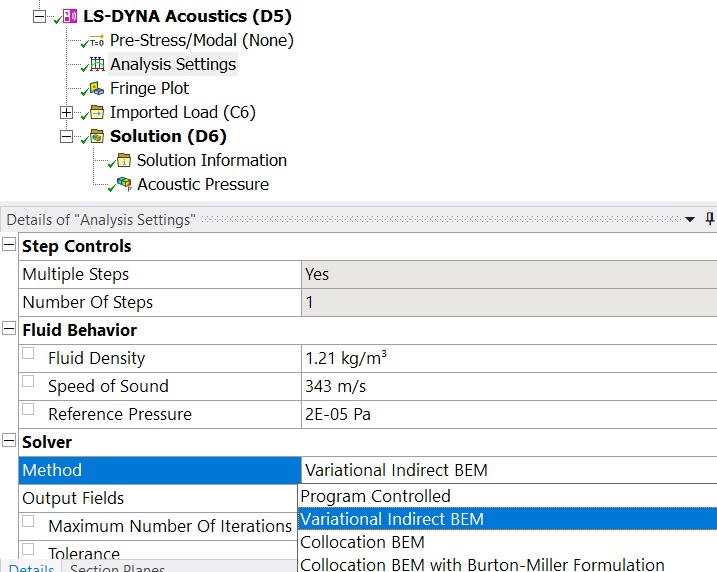

Using Ansys LS-DYNA Acoustics, one can also solve acoustics problems using BEM (Boundary Element Method):

Ansys Sound

Acoustics Sound blends Ansys’s simulation and NVH testing. Here are some of the scenarios where Ansys Sound is used:

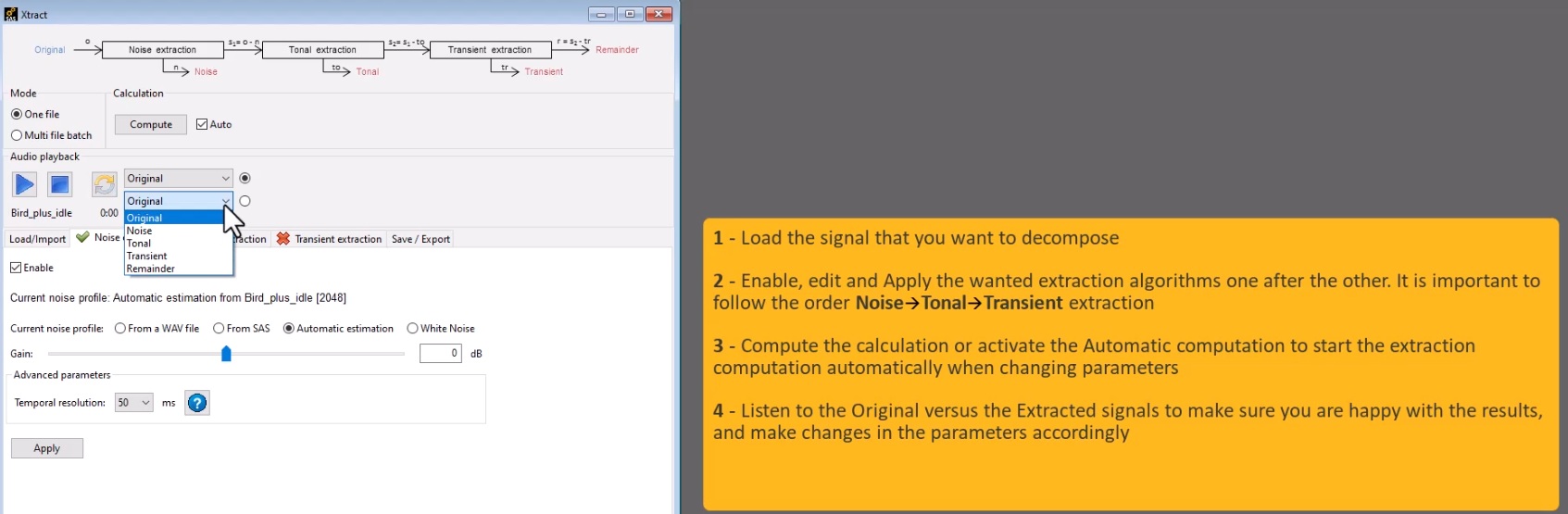

Cleaning Acoustics Test Data:

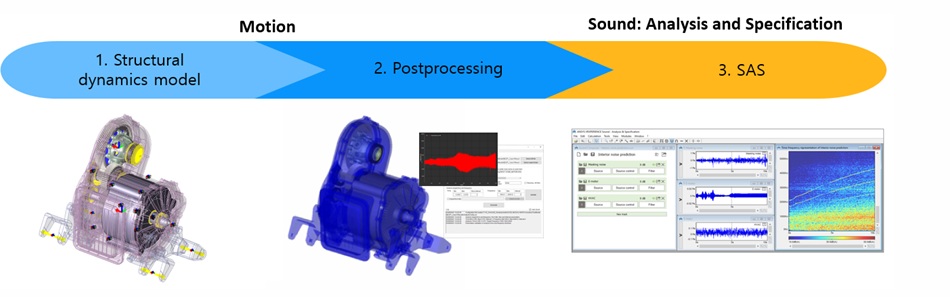

Simulation Workflow:

Ansys Sound interfaces with different Ansys simulation modules. As an example, here is the workflow from Ansys Motion to Ansys Sound.

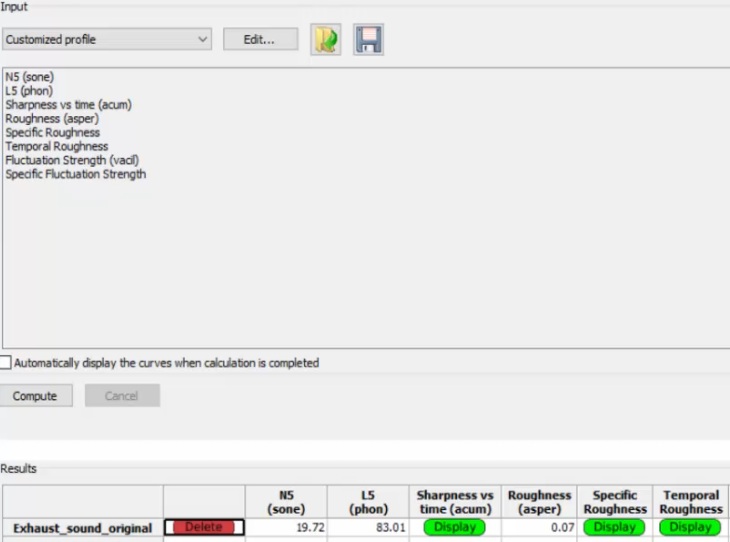

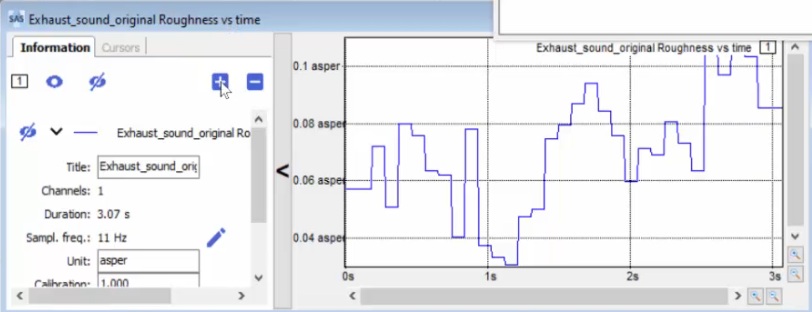

Sound Quality Assessments:

One can compute and display several sound quality metrics whether these sounds have been simulated from Ansys simulation or measured from NVH testing.

Set NVH Targets:

This tool can be used to set NVH targets for future design simulation iterations with goals to improvise a sound quality metric, reduce the overall sound dB level, meet a specific state environmental regulation, etc. by filtering certain orders from the color map.

Noise Source Identification:

Identifying what are the sources that contribute to an overall noise signature obtained from simulation or measurement often poses a significant challenge to an NVH engineer. Ansys Sound has the built in tools to accomplish this challenge.

Conclusion

Ansys’s NVH solutions bring vibration and acoustics together in one connected workflow, linking simulation and test data so engineers can predict, diagnose, and improve NVH performance earlier in the design cycle. By combining Mechanical NVH tools, Mechanical Acoustics, and Ansys Sound, teams can validate results, identify noise sources faster, and set clear NVH targets with confidence. The end result is fewer prototype iterations, smarter design decisions, and quieter, higher-quality products delivered to market sooner.

Balaji Benjamin, Ph.D., Mechanical Engineering

Senior Staff Engineer, SimuTech Group

With 13 years at SimuTech Group and more than 20 years of experience in NVH simulation and testing, Balaji supports customers across vibration and acoustics workflows, including noise source evaluation, correlation to test data, and performance-driven design refinement. He holds a Ph.D. in Mechanical Engineering from the State University of New York at Binghamton.