ROCKY DEM | Ansys CFD Integration and Fiber Modeling

Engineers must comprehend how particles interact with equipment, fluids (liquids and gases in the case of particle-fluid systems), and other particles in order to properly develop products since particles are everywhere. In order to create, evaluate, and conduct virtual experiments as well as “what-if” scenarios that reduce time and costs and speed up time to market, these applications use CFD-DEM techniques.

Did you know that Rocky and Ansys Fluent are utilized (in tandem) in a variety of applications, such as particle systems for handling solids and liquids, across a wide range of industries? Continue reading to learn more about the advantages of simulating these flow-driven, fluid-solid scenarios and to see examples from a few different fields that make use of the special features of Rocky-Fluent coupling.

Ansys Fluent and Rocky Coupling Application in Medicine and Pharmaceuticals

Tablet Coating Simulation

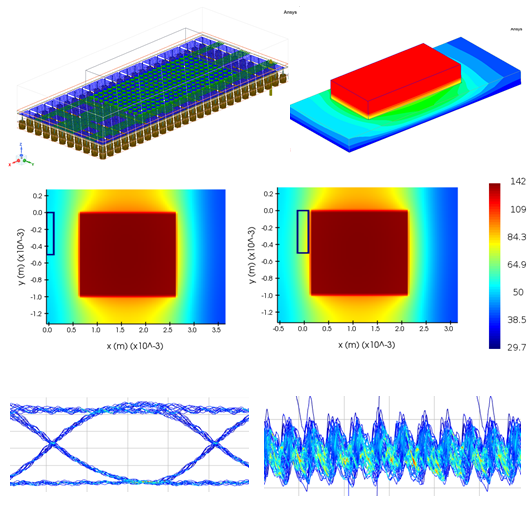

To mimic tablet coating procedures, Ansys Fluent and Rocky are utilized. Rocky can compute the fluid forces acting on the particles and accurately depict shapes, including special convex and concave shapes. To determine coating homogeneity, adhesive/cohesive materials can be modeled.

Using Rocky DEM and Ansys Fluent in full coupling, a drying process in a tablet coater has also been successfully simulated.

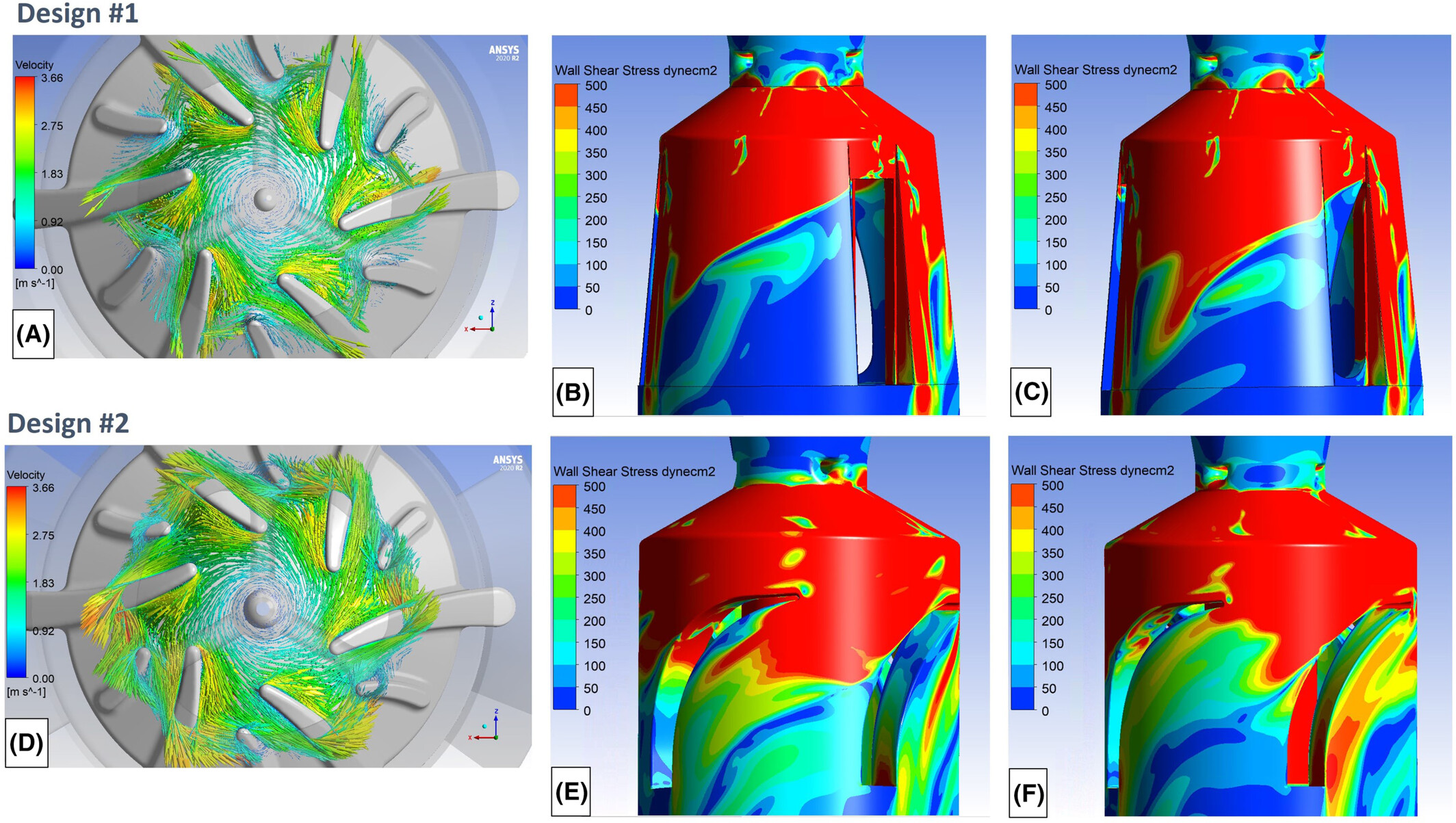

Asthma Inhaler Simulation

To administer the proper dose to the patient, it is important to comprehend how dry powder drugs are activated in an asthma inhaler and subsequently travel through the human airway. Engineers may simulate how particles are moved and deposited in a human airway using a Rocky DEM – Ansys Fluent coupling.

Latest Rocky DEM and Ansys CFD Integrations

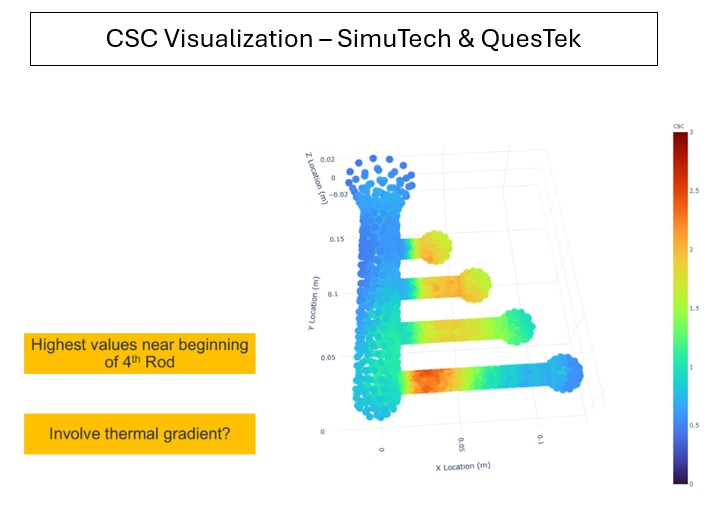

In addition, the latest release of Rocky DEM builds upon innovative multi-core and multi-GPU engines providing unmatched ANSYS CFD integration and fiber modeling.

It also expands the range of multiphysics particle-dynamics simulation with improved features and new models.

- ANSYS CFD Integration Improvements.

- Coarse Grain Model (CGM)

- Liquid Film and Bridge Model

- Plastic Fiber Deformation

- Discrete Breakage (available for fiber, shell and solid particles)

- Volume Filling Particle Initialization

- Unified Particle and Boundary Collision Statistics

- Contact Data Visualization and Post-Processing

- Ray Tracing for Particle Coating Analysis

For more, visit the official Rocky Installation page.