CFD Optimization

SimuTech Group has several optimization tools, using both parametric and non-parametric methods, that intelligently guide the optimization process.

SimuTech Group has several optimization tools, using both parametric and non-parametric methods, that intelligently guide the optimization process.

The evaluation of design changes is a strength of simulation in general. Once an initial model is solved, resolving with new conditions and/or geometry can be as simple as updating the model and rerunning it.

Modeled direct shape optimization of after-treatment devices for an automobile. This method used non-parametric optimization to produce a unique design with performance superior to the original design.

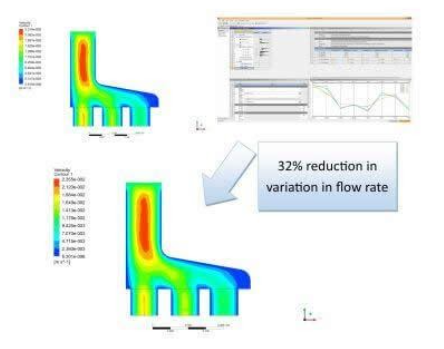

Optimized the fluid flow distribution across manifold design used in the polymer extrusion industry. The simulation required modeling a high-viscosity Non-Newtonian fluid and then evaluating the effect on the distribution to changes in the manifold shape.

Simulated the flow patterns that are used to stabilize membranes used in an industrial process, with the goal of optimizing an industrial sensor’s membrane measurement capability.

Calculated and then optimized the fluid shear forces acting as a cleaning process on a cleaning tank which was generated by transient turbulent waves. Once the initial model was created, the process was optimized to reduce the residence time the tubes were in the tank.

The turbulent mixing characteristics inside an oil storage-tank and resulting tank fluid velocities were predicted and then used to optimize the mixing process, reducing the mixing time of the mixer.

Our team of experienced engineers can assist you at any step of your process.