Flow Foundation (Fluids) Services

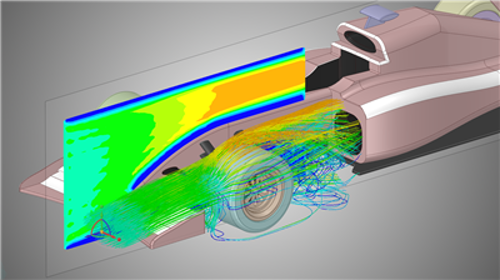

Computational Fluid Dynamics (CFD) models are built on the ability to calculate the flow with the variation in velocity and pressure throughout the fluid volume.

Computational Fluid Dynamics (CFD) models are built on the ability to calculate the flow with the variation in velocity and pressure throughout the fluid volume.

CFD models have been extended over time to include more complex physics like combustion, multiphase, detailed turbulence, aeroacoustics, and coupling with other physics solvers. These original, highly validated CFD models are still used today when the more complex models are not needed, and they can answer a significant number of fluid problems.

However, often times, it takes a skilled fluids engineer to bridge the gap between computational analysis and the environment in which real-life application is being conducted. A seasoned engineer would understand and apply this nuance to the mathematical models, which is the level of expertise SimuTech Group can provide to your business.

Predicted the change in turbulent pressure drop in a complex large-scale duct system preceding the gas turbines in a gas-fired power station due to the retrofitting of additional structural members. (Power Generation).

Calculated the supersonic turbulent lift and drag coefficients of various wing profiles at various angle of attacks and altitudes. Compressibility and high-speed energy effects were included as well as the accurate prediction of the turbulent shear forces and separation points. (Aerospace).

Analyzed the aerodynamic drag forces and their corresponding effect of geometry variations to the aerodynamic design of add-on car body kits for a current on-road vehicle. (Automotive).

Simulated the transient dispersion due to an accidental release and flashing of a volatile gas in a chemical processing plant. The simulation of the gas dispersion was used to evaluate different HVAC designs. (Building Design).

Optimized the time that contaminants were in contact with disinfectant by calculating the turbulent mixing for several different feed streams to different configurations to different baffle and flow configurations. (Water & Waste).

The volume of the fluid that travels a given distance in a given amount of time remains constant as fluid passes from a bigger conduit to a narrower one. However, because the narrower pipe’s width is smaller, the fluid must flow more quickly (and under greater dynamic pressure) in order to cover the same distance in the same amount of time.

Our team of experienced engineers can assist you at any step of your process.