Thermal Analysis Simulation Consulting

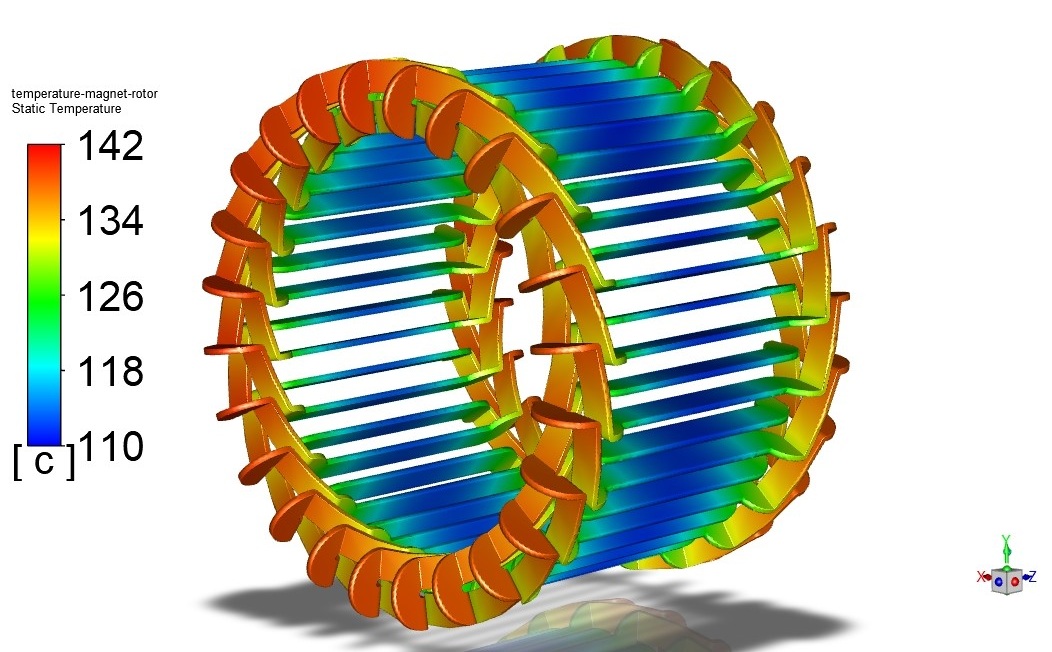

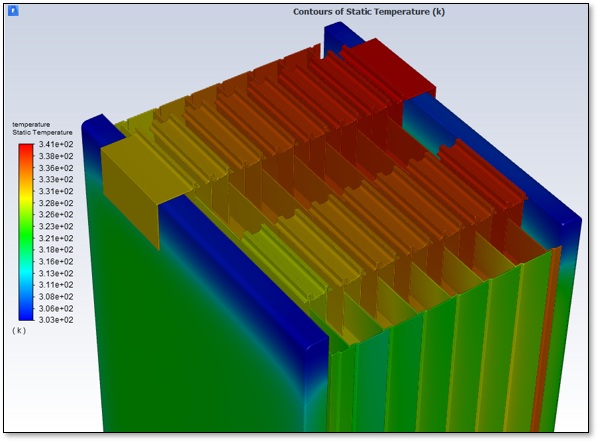

Thermal analysis simulation plays a crucial role in engineering by leveraging Computational Fluid Dynamics (CFD) to calculate heat transfer due to conduction, convection, and radiation through fluid and solid regions. With accurate thermal insights, engineers can optimize designs for improved performance and safety.