FEA Consulting Services for Structural & Thermal Applications

Ensure the structural and thermal integrity, performance, and reliability of your designs with our expert FEA consulting services.

Ensure the structural and thermal integrity, performance, and reliability of your designs with our expert FEA consulting services.

SimuTech Group has been in the structural analysis and FEA (finite element analysis) consulting business for 40+ years. With approximately 30 FEA engineers on staff and over 400 combined staff-years of FEA consulting experience, we have the expertise to meet your most challenging structural and thermal simulation needs.

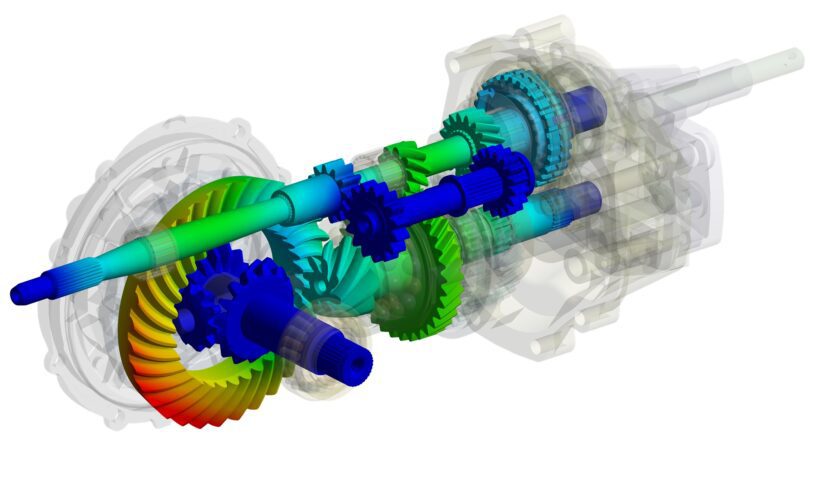

We use the powerful Ansys suite of FEA tools including Ansys Mechanical, Ansys LS-dyna, Ansys Motion and Ansys nCode DesignLife on a daily basis. Our engineers will guide your teams with meaningful FEA simulation results, results interpretation, and conclusions that allow you to make data-driven structural and thermal design decisions and bring your products and processes to market ahead of deadlines.

SimuTech Group also offers expertise in optimization and robust design methods. If your designs must operate over a broad range of conditions and are built from components with real-world manufacturing tolerances, optimization can make a significant difference. You’ll realize robust performance over a wide envelope of operating conditions and reduce warranty costs.

Our structural and thermal analysis consulting engineers have experience in a vast array of industries that inherently benefit from FEA, including:

FEA can be used to predict the performance of a given design under a diverse array of loading conditions.

Under what internal pressure will it burst? Under what static loads will it collapse? At what environment temperature will thermal stresses result in failure? What is the expected service life under cyclic loading? Will operating the design within a specified frequency range (operating speeds) excite resonant frequencies that will prematurely damage the structure? Will existing cracks in the structure grow to the extent of catastrophic failure under a specified number of load cycles?

SimuTech Group’s expert FEA consulting engineers have successfully answered these questions many times in our 40+ years in the business. We welcome the opportunity to partner with you in developing next generation designs by supporting your FEA related simulation needs.

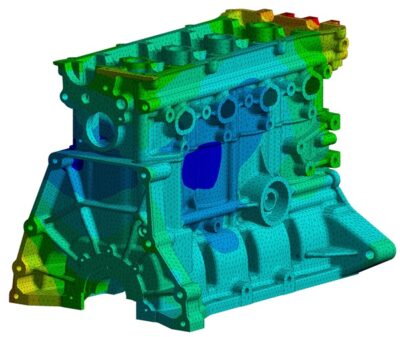

Static Structural

Linear Dynamics

Nonlinear Dynamics

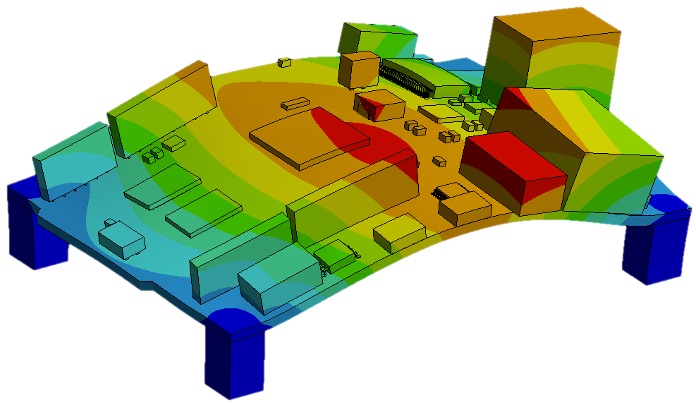

Thermal Analysis and Heat Transfer

Composite Components and Structures

Fatigue

Fracture Mechanics

Acoustics

Coupled Physics

Optimization and Design of Experiments

Our team of experienced engineers can assist you at any step of your process.