Experimental modal analysis is a vibration testing technique for determining the natural frequencies, mode shapes and damping ratios of a structure.

With over 30 years of service, SimuTech Group has tested steam turbines, gas turbines, pumps, blowers, compressors, foundations, buildings, optics, piping, and many more structures for wide variety of industries. Industries served include aerospace, automotive, military, electric power generation, research and development, tool and die, nuclear, petrochemical, air conditioning and refrigeration.

SimuTech Group’s repertoire of excitation techniques include hammer impact (rap, bump, or bonk), electro-dynamic shaker (exciter), operating modal analysis, piezoelectric actuators, and multiple input multiple output (MIMO). SimuTech Group’s modal testing service offers state-of-the-art techniques at competitive prices with a strong commitment to customer service.

Experimental modal analysis is one of the principal techniques for validating structural FE models. Most analysts will agree that applying boundary conditions and determining system properties which pose the greatest modeling challenge. Correlation of experimental and analytical natural frequencies can verify that modeling data such as geometry and material properties are accurate and that assumptions about boundary conditions are valid.

Modal Assurance Criterion (MAC) is used to quantify the correlation between experimental and finite element modal analysis results. Modal testing can also determine the modal damping ratios that are crucial for dynamic stress and fatigue life calculations.

These modal parameters may be used for finite element analysis (FEA) model validation (correlation) and refinement, failure investigation, vibration troubleshooting and diagnostics, and quality assurance.

Due to the versatility of modal testing it can go by several names such as resonance test, natural frequency measurement, frequency response test (FRF), modal survey, or modal vibration test to name a few.

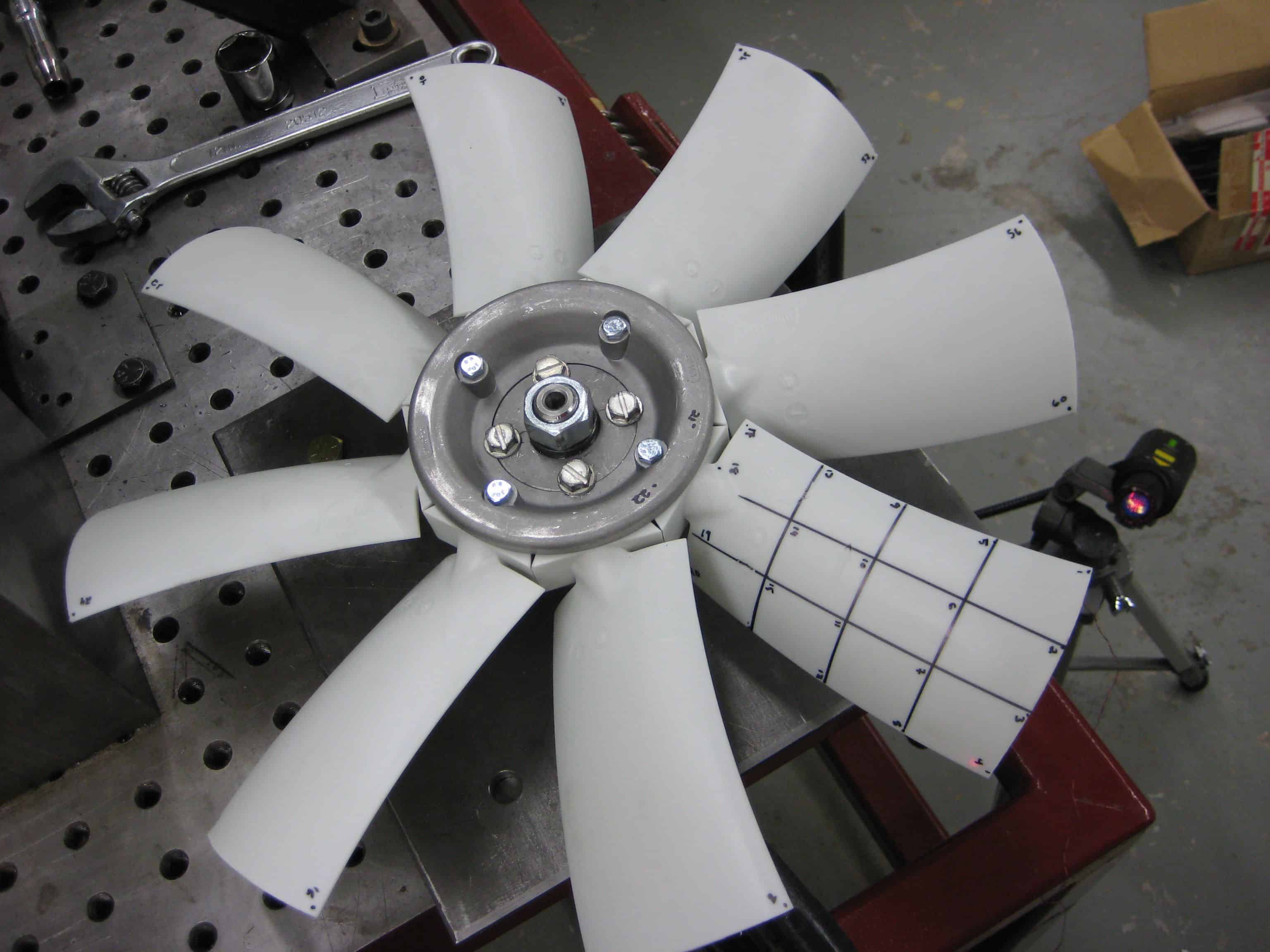

During modal testing or modal analysis, an instrumented hammer, electromagnetic shaker, or piezoelectric actuator is used to excite vibration of the test article.

The vibration amplitude and phase in response to the excitation is measured at multiple locations using sensors including accelerometers and laser vibrometers. Frequency response functions are calculated with a dynamic signal analyzer.

Curve fitting techniques are used to extract the natural frequencies, mode shapes and damping ratios of a structure.

Recent modal test applications include flight qualification of helicopter modifications, mixed flow impellers, gas turbine blades and an optical table.

The modal assurance criterion (MAC) is a technique for quantifying the comparison of mode shapes from two sources. A MAC value greater than 90% generally indicates highly correlated modes. SimuTech engineers often use MAC to compare the mode shapes from two test articles or to correlate the results from a modal test with those from a corresponding finite element analysis.

For new, refurbished, or reverse engineered turbine blades (buckets) to ensure that natural frequencies are within specifications.

Measure the dynamic response characteristics of an airframe with MIMO signal processing and analysis.

Measure and analyze blade weight and the COG location to determine the optimum blade stacking position.

Our team of experienced engineers can assist you at any step of your process.