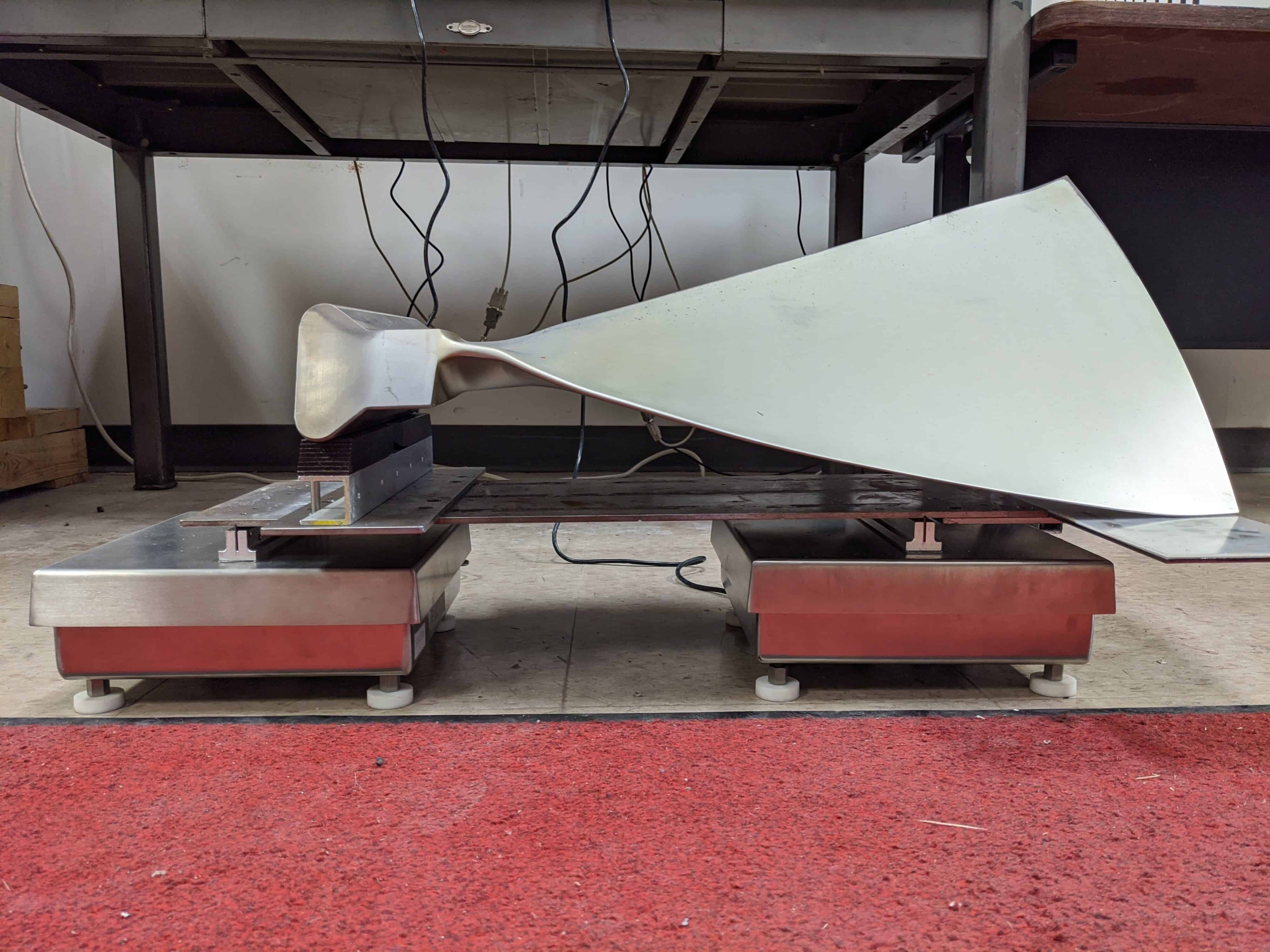

Blade Moment Weigh Testing

Moment weighing is a technique for locating an object’s center of gravity.

Moment weighing is a technique for locating an object’s center of gravity.

During moment weighing, blade weight and the center of gravity location (CG) are measured and analyzed with a software program to determine an optimal blade stacking position (loading chart) that minimizes blade row unbalance.

Blades need to work under a high-load, high-speed, and high-vibration environment, and improper stacking or installation of the blades in a turbine can result in costly delays or down time due to potential imbalances during startup.

During standard service and maintenance, mixing new and used blades may be a viable option, but moment weighing should always be done fresh on a whole row of blades, whether they are new, used, or a combination of the two. It should also be done whenever one or more blades/seals are physically modified. This helps minimize the number of balance weights that need to be added to the turbine after final assembly.

SimuTech Group utilizes a proprietary, portable moment weigh system that allows us to perform onsite moment weighing anywhere in the world. It has also been shown to be reasonably insensitive to temperature allowing for moment weigh in less than ideal temperature conditions.

To match the blade specifications for partnering businesses, SimuTech Group has moment weighed turbo blades and seals ranging in length from 1 to 60 inches (4 oz to 250 lbs) spanning multiple industries and application categories.

Our team of experienced engineers can assist you at any step of your process.