Simulation facilitates faster innovation, lower costs, and can shorten the regulatory processes in the healthcare industry, ultimately saving and improving countless lives.

February was first proclaimed as American Heart Month in 1964 by President Lyndon B. Johnson. Since then, heart disease has remained a leading cause of death in the United States. By raising awareness about heart health throughout February, we can help to reduce the burden of heart disease and help people live longer, healthier lives.

Our engineering team has worked on multiple studies modeling the heart and devices supporting heart function. Read on to learn more about the expanding role of using computational fluid dynamics modeling for cardiovascular devices.

Total Artificial Heart Computational Fluid Dynamics: Modeling of Stator Bore Design Effects on Journal-Bearing Performance

SimuTech Contributing Engineers:

Maryam Khelghatibana, Sr. Staff Engineer

Mark S. Goodin, Principal Engineer

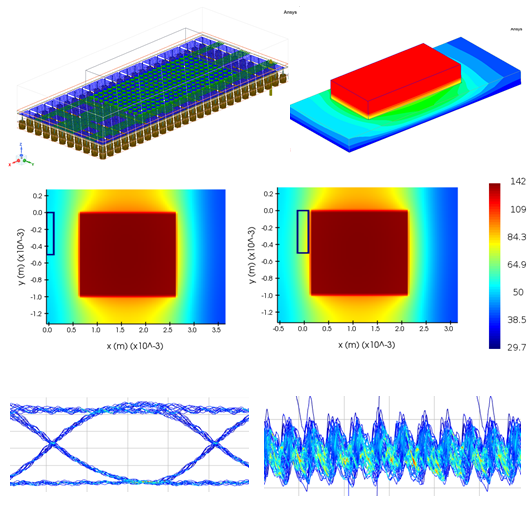

Ansys software was used to model and compare performance of a continuous-flow total artificial heart (CFTAH) under different operating conditions. The CFTAH is a centrifugal blood pump that utilizes a rotating assembly which is magnetically and hydrodynamically suspended. The simulation results guided the selection of a new bearing design which improved the pump’s performance and biocompatibility.

Characterization and Development of Universal Ventricular Assist Device: Computational Fluid Dynamics Analysis of Advanced Design

SimuTech Contributing Engineers:

Mark S. Goodin, Principal Engineer

Michael S. Showalter, Lead Engineer

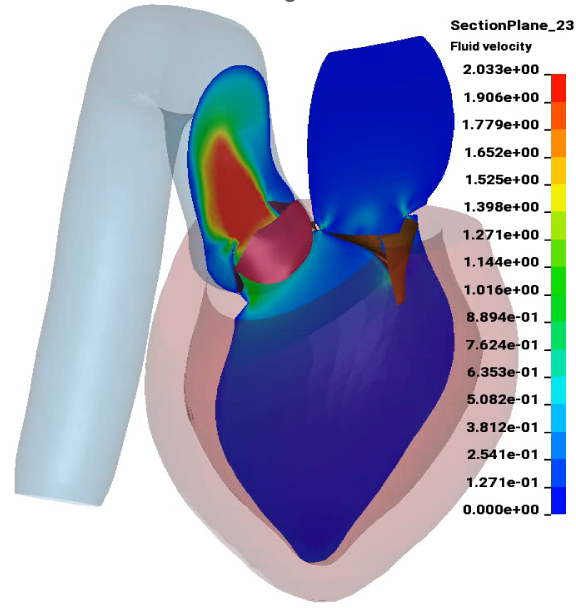

The primary objective for this computational fluid dynamics (CFD) study was to analyze the biventricular performance of an advanced ventricular assist device (AVAD) across a wide range of operating conditions.

An AVAD CFD model was created and validated using in vitro hydraulic performance measurements taken over conditions spanning the device’s intended operating range. The CFD results helped demonstrate the unique ability of the AVAD in providing the desired left or right ventricular hemodynamic support using a single device design.

Computational Fluid Dynamics Model of Continuous-Flow Total Artificial Heart: Right Pump Impeller Design Changes to Improve Biocompatibility

SimuTech Group Contributing Engineers:

Mark S. Goodin, Principal Engineer

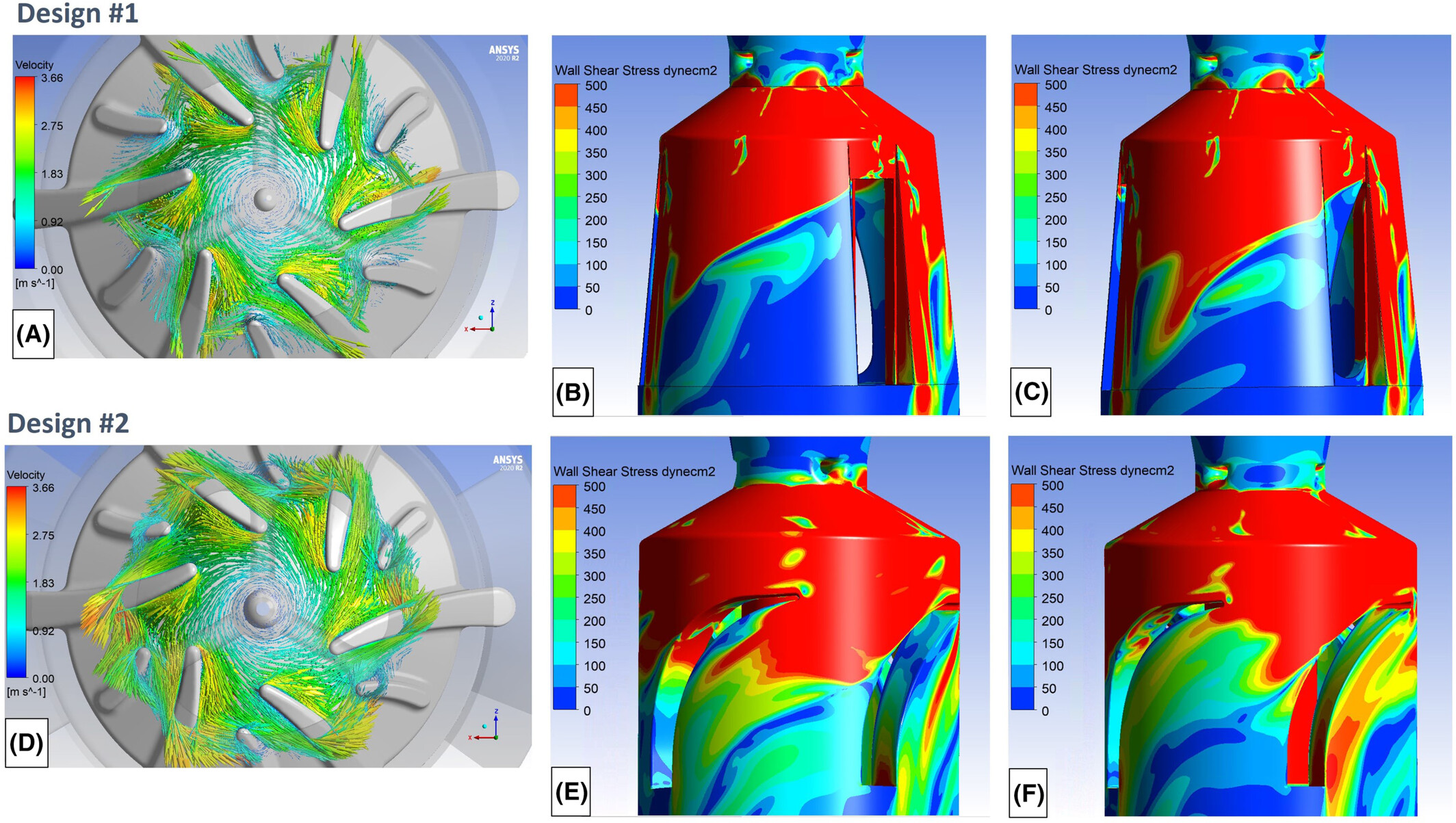

This study aimed to (1) use computational fluid dynamics (CFD) to gain insight into the differences in the flow fields surrounding the blood pump’s left and right impellers, and (2) leverage that knowledge in identifying an improved right impeller design that could reduce the potential for thrombus formation.

Transient CFD simulations were used to mimic in vivo conditions for the continuous-flow total artificial heart (CFTAH) and revealed significant blade tip-induced flow separation and clustered regions of low wall shear stress near the right impeller that were not present for the left impeller.

The next-generation right impeller design reduced both the flow separation from the blade leading edges and the extent of low shear regions near the right impeller surface, while maintaining the desired hydraulic performance of the original CFTAH design.