![]()

Testing product integrity requires either numerous physical prototypes or a concentrated 3D CAD model.

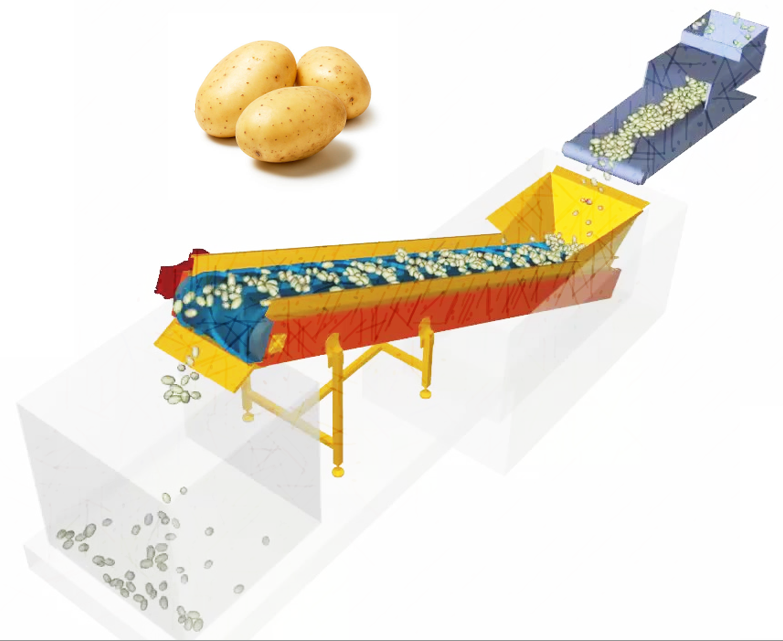

Whether creating a smart-product, motorcycle helmet, pet-related product, or food processing equipment, manufacturers are all looking to create worthwhile products for consumers with meaningful margins, all while beating the competition to the market.

From 4K televisions to washing machines, personal care products, and food and beverage, trendsetters in the consumer goods industry are advancing their innovation pipeline with the powerful stimulus known as simulation.

These software solutions permit engineers to produce competitively differentiated products to market at an accelerated rate, at lower cost than their peers, all-the-while satisfying the sustainability concerns of their clientele and the community at large.

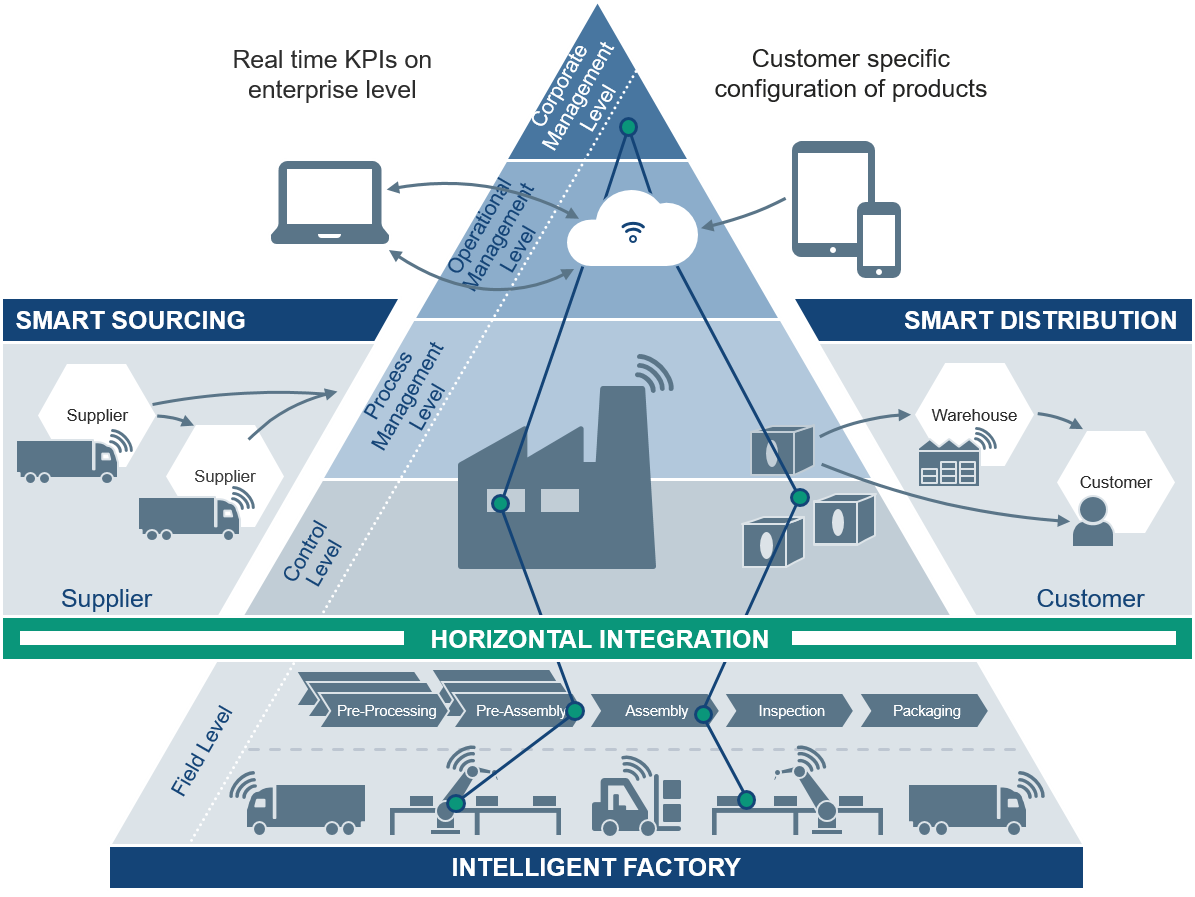

Introducing a Total Manufacturing Workflow Solution – a comprehensive solution for designers, engineers, and analysts that spans the full workflow, from design for additive manufacturing (DfAM) to validation, process simulation, and material exploration (even those of atypical to standard assembly lines).

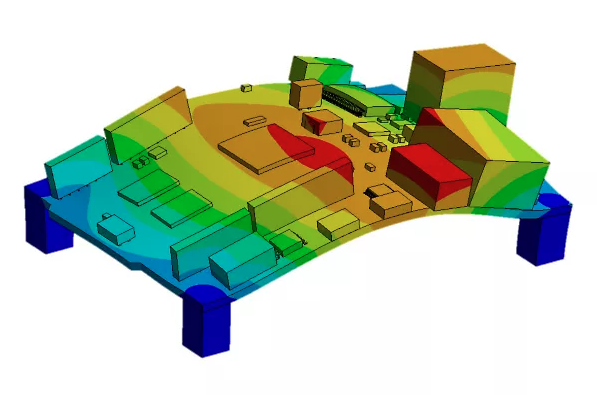

Simplifying 3D Printing Part Orientation – engineers can determine the suitable orientation using heatmapping technology to orient components and specify build parameters. The new BPT enables users to export files directly to a 3D machine, control scaling, slicing, and other specific machine parameters.

Enhance ROI by Building Precision Parts – Rapidly check for distortion, stress and strain regions, predict blade crash, and export for advanced post processing analysis. Differing levels of simulation fidelity empower users to navigate from estimation to detailed thermal analysis in seconds.