Computational Aeroacoustics (CAA) Consulting Services

Simulate and reduce noise from airflow, turbulence, and vibration using computational aeroacoustics and advanced CFD tools.

Simulate and reduce noise from airflow, turbulence, and vibration using computational aeroacoustics and advanced CFD tools.

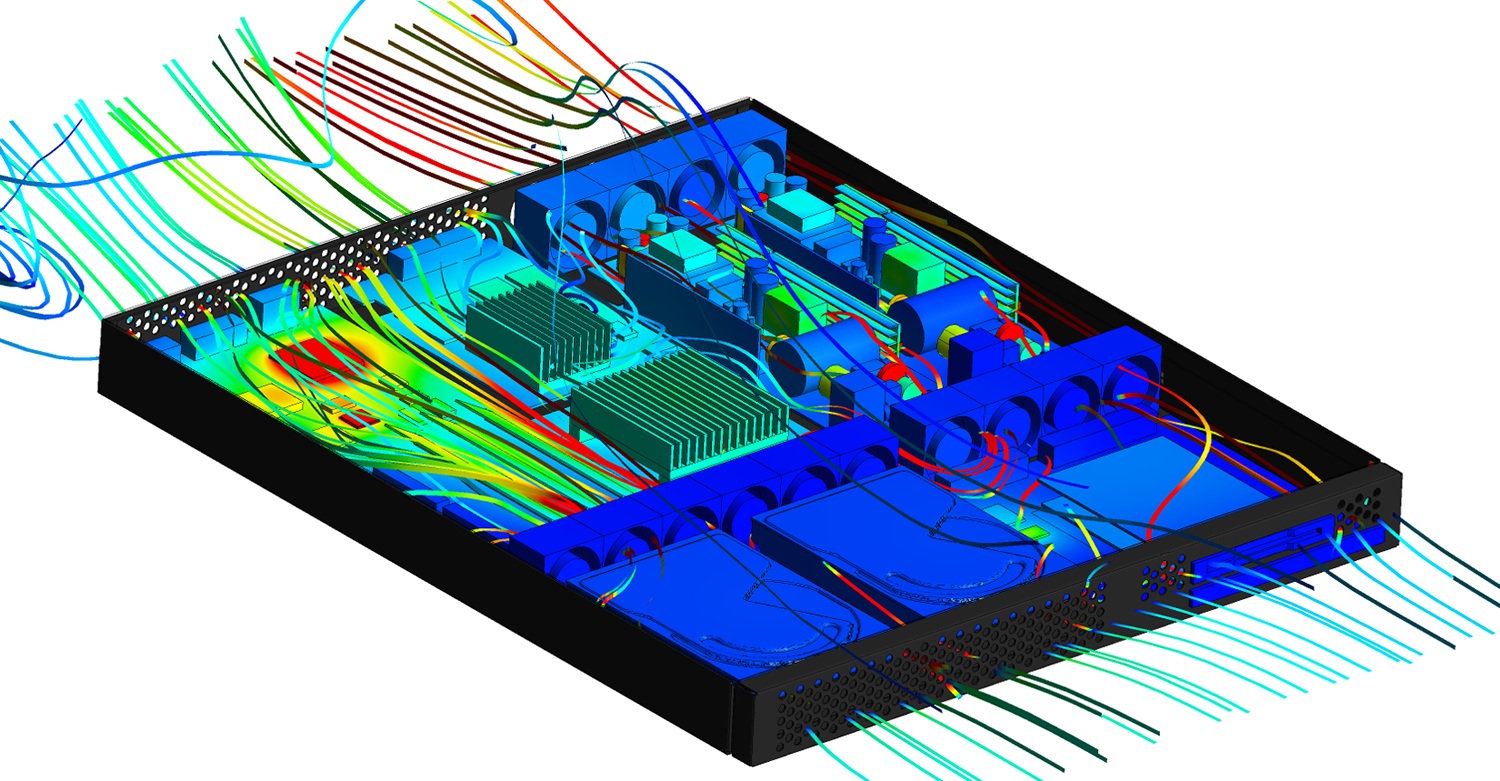

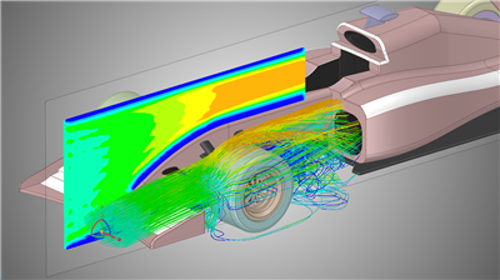

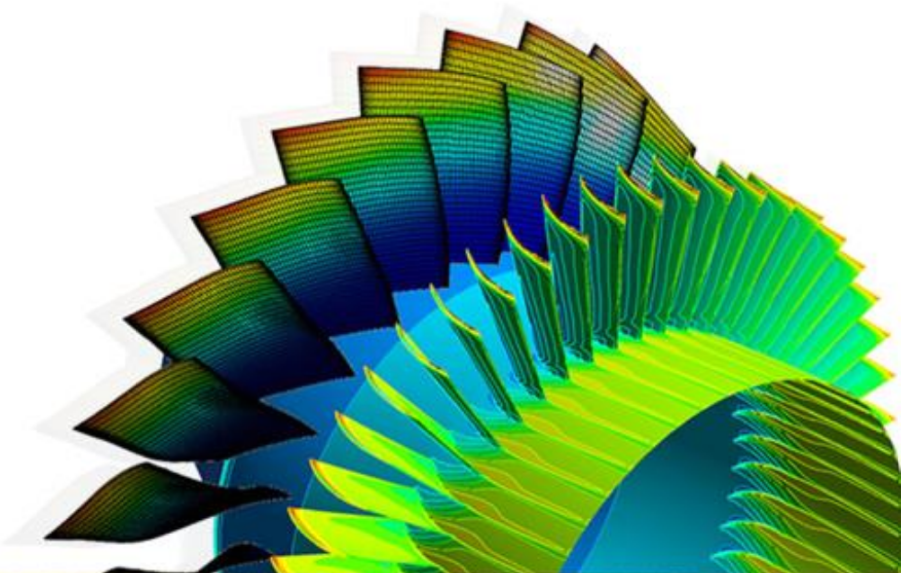

Aeroacoustics is the study of noise generated by turbulent fluid flow or aerodynamic forces. Using Ansys CFD software, one can simulate aeroacoustics for a broad range of industrial applications. Common applications include fans, blowers, jets, HVAC, and exhausts. Based upon the CFD simulation results, one can post-process the predicted flow fields to not only assess sound power but also evaluate several sound quality metrics that can be used for noise source identification and “what if” design scenarios.

By coupling Ansys Mechanical and CFD software within a single Ansys Workbench Project, one can effectively conduct vibro-acoustic simulations to predict structure-borne noise resulting from fluid pressures. At SimuTech Group, we have experience in modeling aeroacoustics and vibro-acoustics and can assist your efforts in reducing aeroacoustics related noise.

Aeroacoustics consulting engineers from SimuTech Group are respected experts in the combined study of aerodynamics and acoustics, or “aeroacoustics,” across the US and Canada.

Our engineers are well-versed in using cutting-edge Computational Fluid Dynamic (CFD) modeling technologies to solve challenging engineering and architectural design issues. As a result, they offer client management-design teams the solutions they need to either implement the most recent, high-performance system or building designs or to identify and fix an existing issue.

In addition, aeroacoustics CFD simulations from SimuTech Group are used to simulate aerodynamic and hydraulic designs (generically referred as “fluid flows”). The CFD science enables the following determinations:

Answer Air and Fluid Flow Questions Quickly and Reliably

When fluid flows inside or around a building, advanced computer modeling can predict what will happen statistically, graphically, and animatedly. In order to model a 3D structure, our engineers replicate real-scale geometry during pre-construction CFD (computational fluid dynamics) study.

Computer simulations of the suggested layouts, choices, and/or various physical, fluid, and/or climatic conditions are carried out, providing information and visuals of what will occur in reality when certain conditions, physical shapes, events, and weather situations occur.

Finally, these findings are then used to inform the design during the engineering phase or as suggestions for correction – as a source of information, ideas, or tactics.

Using the principles of established fluid flow, CFD forecasts 3D aerodynamic and hydraulic performance inside and outside of a structure, enabling the capacity to troubleshoot and confirm effective designs. Essentially, it enables decision-makers, engineers, and regulatory agencies to see what happens within and around a hypothetical or actual structure with a level of visual animation and detail that is impossible to see firsthand using wind tunnel modeling, smoke tracing, and/or area sampling.

When SimuTech Aeroacoustics CFD skills are used during the project design phase, theoretical notions are confirmed and cost effectiveness is achieved through system efficiencies. Expensive and useless “cut and try” attempts are prevented thanks to this robust diagnostic tool employed with computational aeroacoustics (CAA) consulting.

CFD offers insight into how the design will perform based on a solid scientific foundation by modeling fluid flow in 3D on a prospective or existing design. If necessary for the project, recommendations can be experimentally supported through large-scale wind tunnel performance. Or, via scale model testing on our own Aeroacoustics aerodynamic flow bench.

An engineering management team will receive sound solutions from our CFD design analysis and/or remedial diagnostics. This is our promise so that your team can make decisions quickly, choose the best design, and save money on prototyping.

Allow a skilled SimuTech Group Aeroacoustics engineer to help you create a successful protocol and a timetable for deployment. Let us ease your job with our nearly 25 years of experience and dozens of successful projects under our belt.

Additional Computational Aeroacoustics (CAA) Consulting Services include:

SimuTech Group’s CFD consultants apply computational aeroacoustics to help engineers analyze and reduce noise generated by airflow, turbulence, and vibration. From aircraft engines to HVAC systems, our simulations reveal hard-to-measure acoustic behaviors, enabling smarter design decisions without the need for excessive prototyping or physical testing.

Let’s work together to reduce the noise and enhance performance.

Our team of experienced engineers can assist you at any step of your process.