Background

Allerion Oilfield Services (www.allerion.com) develops products and solutions for the petro-chemical industry. Currently, Allerion is engaged in developing and deploying static mixers for desludging and destratification of large crude oil storage tanks all over the world. Their simple and easy to deploy “DS Jet” mixer designs allow their customers to recover large amounts of oil product trapped in settled sludge. With rising oil prices, the DS Jet mixer has become a must-have tool with a great return on investment. With demand high, Allerion is aiming to develop this line of products further.

Challenge

The production of a blast chamber and associated components is extensive and so testing of multiple design iterations is not very feasible. Computer simulation was required to validate a design before a prototype is produced.

The simulation is highly complex due to several factors. The speed of the event requires very small-time steps. The interaction between the solid, liquid, and gas regions is difficult to capture.

The simulation is highly complex due to several factors.

Solution

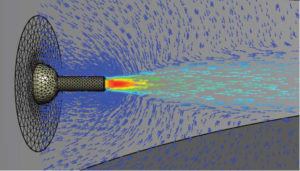

SimuTech Group was employed to perform the CFD simulations of two designs and compare the flow patterns and velocities required for desludging. Detailed CFD models were created for use within the Ansys CFX advanced flow solver. CFX is uniquely suited due to ability to model transient boundary motions (allowing mixer motion) coupled with customized computational mesh deformation routines. Furthermore, advanced post processing techniques allowed advanced visualizations and animations to be made, to fully understand performance.

![]()