Background

Astroscale U.S. is a leader in on-orbit servicing, dedicated to developing innovative solutions for satellite servicing and logistics. As the space industry evolves, the company faces unique challenges in designing reliable, cost-effective, and high-performance systems that can withstand the harsh conditions of space. To meet these demands, Astroscale U.S. sought a solution that would enable rapid, accurate, and efficient design validation.

At-A-Glance

Technology Used

- Ansys Mechanical

- Ansys Medini

- SimuTech Group training and mentoring solutions

Challenge

Astroscale U.S. needed to conduct rapid, high-fidelity analyses for parts and assemblies in the emerging field of on-orbit servicing under tight timelines and without relying on extensive physical testing.

Outcomes

- Accelerated design validation through in-house simulation capabilities

- Reduced prototyping costs and development timelines

- Greater design flexibility with the ability to explore unconventional concepts

- Strengthened position as a leader in space sustainability and innovation

The Problem

Because on-orbit servicing is an emerging and rapidly evolving field, Astroscale U.S. has to do quick-turn analyses on parts and assemblies. The team needed a high fidelity, in-house virtual environment so that they could take advantage of their existing skills and expertise. Given their tight design and delivery schedules, they need to identify design shortcomings as quickly as possible.

The Solution

To overcome these challenges, Astroscale U.S. contracted SimuTech Group to integrate Ansys Mechanical simulation software into its engineering processes. The collaboration provided Astroscale U.S. with access to online training resources and expert mentoring from SimuTech Group. Through this support, the team quickly became proficient in using Ansys for structural analysis, thermal environments, and launch condition assessments. By leveraging simulation, Astroscale U.S. was able to optimize designs before physical prototyping, reducing both costs and development time.

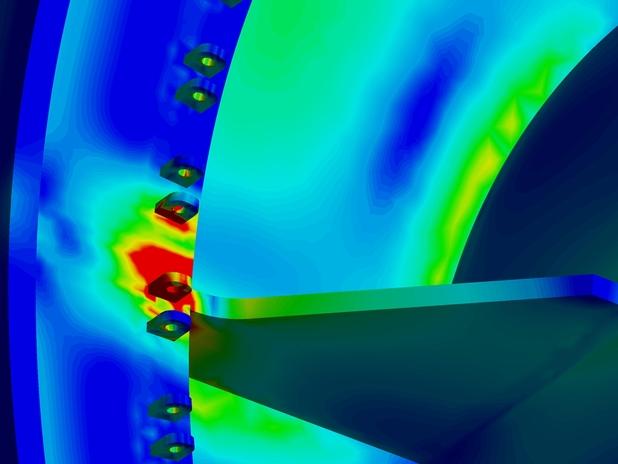

Ansys Mechanical generic simulation image shown for illustrative purposes only.

The Benefits

The adoption of Ansys simulation software has yielded multiple advantages for Astroscale U.S., including:

- Enhanced Innovation: The ability to experiment with unconventional designs while ensuring robustness and reliability.

- Cost and Time Savings: Reduced prototyping needs and faster iteration cycles, leading to lower production costs and accelerated project timelines.

- Greater Independence: The in-house simulation capabilities have decreased reliance on subcontractors, allowing for more control over the design process.

- Industry Leadership: By breaking new ground with cutting-edge solutions, Astroscale U.S. continues to position itself as a leader in on-orbit servicing to make space sustainable.

Ansys allows us to try unconventional designs, look at their performance, and iterate without going directly to prototyping and testing, saving us time and money.

Mark Jesik

Mechanical Engineer, Astroscale U.S.

Conclusion

By integrating Ansys simulation software with the support of SimuTech Group, Astroscale U.S. has transformed its design and development process, ensuring more efficient, cost-effective, and innovative solutions for on-orbit servicing. As the industry continues to evolve, the company remains at the forefront of engineering excellence, leveraging cutting-edge simulation tools to drive future advancements in space technology.

Advancing On-Orbit Servicing with Simulation-Driven Engineering

At SimuTech Group, we help pioneers like Astroscale U.S. lead the way in on-orbit servicing with cutting-edge Ansys simulation tools. Whether you’re optimizing structures for launch conditions or validating thermal performance in extreme environments, our expertise empowers your team to move faster, reduce risk, and innovate with confidence. Partner with SimuTech to bring your space technologies to life, and contact us today!