Automatically Regenerate Mesh with Nonlinear Mesh Adaptivity in Ansys Mechanical

In many industries — including aerospace, defense, automotive, power generation, oil and gas, and power electronics — simulation software Ansys Mechanical is reputed for its ability to work with CAD geometry through meshing, contacts, constraints, solving, parameterization, and optimization.

Users often work with complex models in Mechanical that involve materials like elastomers, gaskets, plastics, metal forming etc. In an analysis where geometric distortion (change of initial shape) is minimal, controlling the quality and size of the initial mesh is sufficient. But with complex models mentioned above the geometry undergoes large distortion and deformation. When geometry is expected to have significant distortion, it’s hard to maintain the quality of the mesh as it deforms and distorts. In these situations, it’s useful to re-mesh to avoid distorted meshes. This can be cumbersome if a manual process of remeshing is involved. Ansys’ Mechanical has a solution for this built in called Nonlinear Mesh Adaptivity (NLAD). In NLAD, 2D and 3D distorted elements can be re-meshed automatically.

What is NLAD?

Simulations which involve elastomers, metal forming, and metallic seals can exhibit large distortions in the mesh that are accompanied by substantial shape changes. As an example, analysis of rubber seals or softened ductile metals to prevent fluid or gas leakage often include severe distortion. In these types of analyses, the shape change is so severe that the quality of the initial mesh is lost.

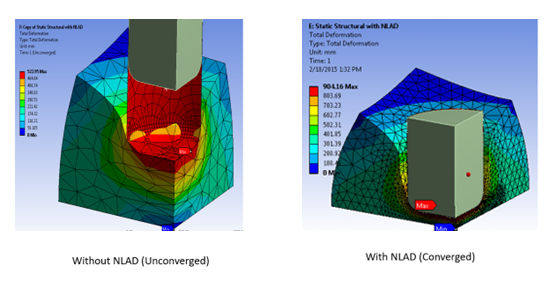

Nonlinear Mesh Adaptivity (NLAD) resolves mesh distortion issues in such analyses. The solver keeps track of the mesh quality, and when distortion is seen, a higher quality mesh is generated. The user has the flexibility to re-mesh the distorted region by refining, maintaining the same size, or coarsening the mesh. In the metal forming example shown below the usefulness of NLAD can be seen. The left image shows the initial model which did not converge due to severe mesh distortion from large deformation. The right image shows automatic re-meshing done by the NLAD functionality and subsequent mesh at the end of the converged solution. NLAD has automatically repaired the mesh distortions that triggered the convergence issues under large deformations. From there, the NLAD process refined the mesh as it distorted to ensure local phenomena are captured correctly. Unlike manual rezoning, mesh nonlinear adaptivity is completely automatic, requiring no user input during solution.

How Does NLAD Work in Ansys Mechanical?

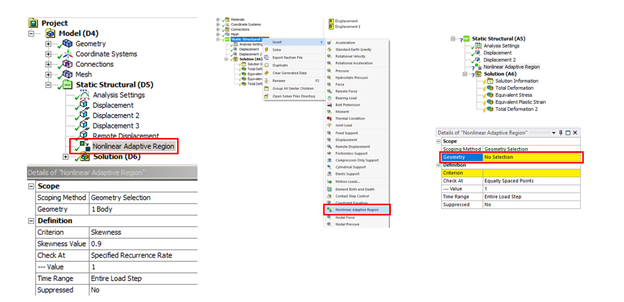

The NLAD tool will automatically re-mesh the geometry. However, the user controls how often this happens. This control is set up through various criteria in the details panel. If one criterion is met during the simulation, it triggers a specific mesh modification algorithm that is linked to that criterion. Mesh nonlinear adaptivity is based on criteria checking at the end of each specified converged substep. If the criteria indicate that it should be done, a new mesh is generated on the currently deformed geometry, and the solution moves on to the next substep.

Three inputs from the user are necessary to set up Mesh Nonlinear Adaptivity:

- Defining Element Components

- Defining Nonlinear Adaptivity Criteria

- Defining Criteria Checking Frequency

To use Nonlinear Adaptivity most effectively, it is important to understand the criterion that will trigger mesh modification. Choices are:

- Energy Based: If, during a substep, an element’s strain energy becomes greater than or equal to the mean strain energy of component(s) to which the element belongs times a user-defined factor, then that element is split and re-meshed.

- Box Based: If, during a substep, all nodes of an element move to within a user-defined region, that element is split and re-meshed.

- Mesh Based: When an element’s skewness is greater than the user-defined threshold, that element is identified as a seed element for remeshing.

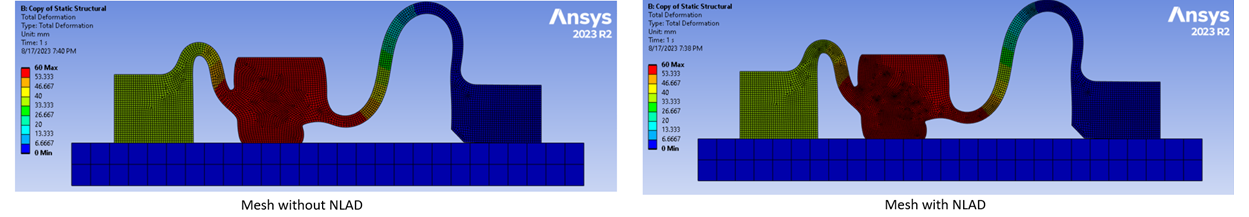

The technique can re-mesh when there is self-contact. This is typical when simulating rubber seals being squeezed into small crevices to prevent fluid or gas leaks in high pressure vessels, pipes, and other mechanical equipment. An advantage of NLAD is controlling mesh discretization errors. A common error with coarse meshes in regions of interest leads to underpredicting the stresses at critical locations. Nonlinear mesh adaptivity can alleviate these issues by monitoring the ability of a mesh to capture variations in stresses and strains and refine them to better capture stress and strain changes in neighboring elements. In the example below, a hyperelastic key undergoes large deformation and contact. The analysis solves fully both with and without NLAD. However, with NLAD activated the solver automatically has refined the mesh in the critical locations of the key such as bends. For very large models or in complex assemblies where the location of hot spot stresses remains unknown, having the solver automatically refine the meshes in selective regions to improve accuracy of results is a very powerful benefit.

The Nonlinear Mesh Adaptivity (NLAD) feature resolves mesh distortion issues in complex large deformation analyses automatically. The solver keeps track of the mesh quality, and when distortion is seen, a higher quality mesh is generated. Unlike manual rezoning, mesh nonlinear adaptivity is completely automatic, requiring no user input during solution. Engineers spend less time manually rezoning for complex large deformation models and more time optimizing their designs, leading to accelerated time to market and more robust product designs.

Looking for Ansys training courses? Our paid offerings can help you and your team accelerate your learning, sharpen your abilities, and help you stay current with latest simulation technologies. Check out our Ansys Training Courses.